Confused about how viscosity links to the forces within fluids? This complex relationship impacts product quality and processing. Let's clarify this fundamental concept simply.

snippet paragraph:

Viscosity directly influences shear stress. Higher viscosity means more force (shear stress) is needed to make a fluid flow at a certain rate. This relationship is key to understanding fluid behavior.

Understanding how fluids behave under force is essential in so many industries. At Martests, where we manufacture rotational viscometers, we see this every day. The connection between viscosity and shear stress is at the very heart of what our instruments measure. In viscometer manufacturing, knowing this precise relationship is crucial for us to create accurate and reliable instruments. Our customers, especially industrial buyers and distributors like Jacky from Italy, value this expertise when they seek customized, high-quality lab instruments. So, let’s explore this core idea.

What is Shear Stress?

Hearing "shear stress" but unsure what it really means for fluids? It’s a hidden force defining how liquids move and resist. Let's break down this important concept.

Shear stress is the force per unit area acting parallel to a fluid's surface, causing layers within the fluid to slide past each other. It's what makes a fluid flow.

Imagine you're spreading honey on a piece of bread. The force you apply with the knife, moving it sideways across the honey, creates shear stress within the honey. It's not a pushing force directly down, but a force that tries to make one layer of honey slide over the layer beneath it. We encounter shear stress all the time. When you stir coffee, pour oil, or even when blood flows through your veins, shear stress is at play. In our factory, when we design our rotating spindle viscometers, we're essentially creating a controlled way to apply and measure this shear stress. The spindle rotates within the sample, and the resistance it feels is directly related to the shear stress needed to make that sample flow at that speed.

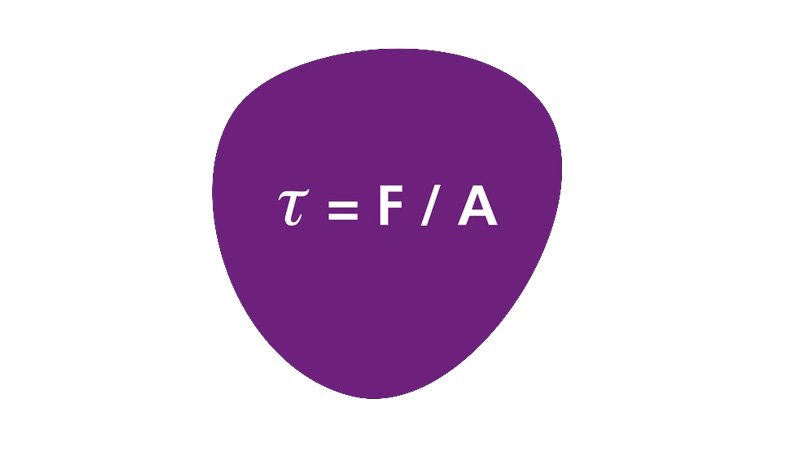

Breaking Down Shear Stress

- Force (F): This is the push or pull you apply. In our honey example, it's the force from your hand moving the knife.

- Area (A): This is the area over which the force is applied, parallel to the direction of flow. For the honey, it's the surface area of the knife in contact with the honey and moving with it.

- Shear Stress (τ): This is calculated as Force divided by Area (τ = F/A). It’s expressed in units like Pascals (Pa) or dynes per square centimeter (dyn/cm²).

Why It Matters

Understanding shear stress is critical because it tells us how much effort is needed to make a fluid move.

| Application Area | Relevance of Shear Stress |

|---|---|

| Manufacturing | Pumping liquids, mixing ingredients, coating surfaces – all involve overcoming shear stress. |

| Product Formulation | The texture of food, cosmetics, and paints (e.g., how easily they spread) is determined by their response to shear stress. |

| Material Science | Characterizing the flow properties of polymers, oils, and other complex fluids. |

For our clients, like purchasing managers from large instrument distributors, explaining this concept helps them understand the fundamental principles behind the viscometers we supply. It's the basis for measuring viscosity.

What is the Relationship Between Viscosity and Shear Stress?

Wondering how viscosity and shear stress actually connect? They are two sides of the same coin in fluid dynamics. Let's explore their direct and defining relationship.

Viscosity is the measure of a fluid's resistance to shear stress. For a given shear rate (how fast layers slide), higher viscosity means higher shear stress is needed to maintain that flow.

Viscosity and shear stress are intrinsically linked. Viscosity, often denoted by the Greek letter eta (η), is essentially the proportionality constant that connects shear stress (τ) to something called shear rate (γ̇, "gamma-dot"). Shear rate is a measure of how quickly the fluid layers are sliding past each other – think of it as the speed gradient within the fluid. The faster you try to make the layers slide (higher shear rate), or the more resistant the fluid is to this sliding (higher viscosity), the more force per unit area (shear stress) you'll need to apply. This is the fundamental principle our Martests rotational viscometers operate on. Our instruments apply a defined rotational speed (which relates to shear rate) using a spindle, and then measure the torque (which relates to shear stress) required to maintain that speed.

The Core Equation

The basic relationship can be expressed as:

Shear Stress (τ) = Viscosity (η) × Shear Rate (γ̇)

This simple equation is powerful. It tells us:

- If viscosity is high, you need more shear stress to achieve a certain shear rate. Think of trying to stir thick molasses versus water.

- If you apply a certain shear stress, a low-viscosity fluid will flow at a higher shear rate than a high-viscosity fluid.

Understanding Shear Rate

Shear rate is the rate of change of velocity at which one layer of fluid passes over an adjacent layer.

| Component | Description | Unit Example |

|---|---|---|

| Velocity (v) | Speed of the fluid layer. | m/s |

| Distance (y) | Distance perpendicular to the flow, between layers. | m |

| Shear Rate (γ̇) | Change in velocity divided by the change in distance (dv/dy). | s⁻¹ |

When we provide our rotating spindle viscometers, cone and plate viscometers, or coaxial cylinder viscometers to distributors or direct B2B clients, we often discuss the shear rates their applications might encounter. This helps them choose the right instrument and accessories for their specific fluids. For example, a customer testing paints might be interested in behavior at both low shear rates (like sagging on a wall) and high shear rates (like during spraying). This understanding is critical for our product design and customization services, allowing us to offer features like variable speed control to cover a wide range of shear rates.

For Newtonian Fluids, What is the State Between Viscosity and Shear Stress?

Dealing with simple fluids like water or oils? Their viscosity behaves predictably with shear stress. Let's examine the straightforward relationship for Newtonian fluids.

For Newtonian fluids1, viscosity remains constant regardless of the shear stress applied or the shear rate. Shear stress is directly proportional to the shear rate, with viscosity as the constant.

Newtonian fluids are the simplest type of fluids when it comes to viscosity. Their defining characteristic is that their viscosity does not change, no matter how much shear stress you apply or how fast you try to make them flow (i.e., regardless of the shear rate). Water, most simple oils, solvents, and air are common examples of Newtonian fluids. If you double the shear stress applied to a Newtonian fluid, its shear rate will also double. Their relationship is perfectly linear. I remember a client who was new to viscosity testing, purchasing viscometers for a teaching lab. Explaining Newtonian behavior was the first step. He needed reliable instruments for basic fluid characterization, and our standard Martests rotating spindle viscometers are perfect for demonstrating this principle.

Key Characteristics of Newtonian Fluids

- Constant Viscosity: The viscosity value (η) is a constant at a given temperature and pressure. It does not depend on the shear rate.

- Linear Relationship: If you plot shear stress (τ) on the y-axis against shear rate (γ̇) on the x-axis, you get a straight line passing through the origin. The slope of this line is the viscosity.

- Equation Reminder: τ = η × γ̇ (where η is constant)

Examples and Importance

| Fluid Example | Typical Behavior | Why This Matters for Measurement |

|---|---|---|

| Water | Flows easily; viscosity is low and constant. | A common calibration fluid and reference point. Easy to measure with almost any viscometer. |

| Simple Oils | Such as mineral oil or some silicone oils. Their viscosity is higher than water but still constant. | Used as calibration standards for viscometers. Their predictable behavior makes them ideal for verifying instrument accuracy. |

| Air / Gases | Very low viscosity, but still Newtonian. | Less commonly measured by rotational viscometers due to very low torque, but the principle applies. |

When we discuss applications with potential customers, like a distributor specializing in lab instruments, knowing if their end-users primarily deal with Newtonian fluids helps us recommend the most cost-effective and suitable Martests viscometer models. For these fluids, a basic rotating spindle viscometer often provides all the necessary accuracy and functionality. The measurement is straightforward: you set a speed, measure the torque, and calculate the viscosity.

For Non-Newtonian Fluids, What is the State Between Viscosity and Shear Stress?

Working with complex fluids like ketchup or paint? Their viscosity changes with force, making the shear stress relationship more dynamic. Let's delve into non-Newtonian behavior.

For non-Newtonian fluids2, viscosity is not constant; it changes with the applied shear stress or shear rate. This results in a non-linear relationship between shear stress and shear rate.

Most fluids encountered in industrial processes and everyday life are actually non-Newtonian. This means their viscosity is not a fixed value at a given temperature; instead, it changes depending on how much shear stress is applied or how fast they are being sheared (shear rate). This is where viscosity measurement gets really interesting and incredibly important for product development and quality control. Think about ketchup: it’s thick in the bottle (high viscosity at low shear), but when you shake it or squeeze it hard (apply high shear stress/rate), it flows much more easily (lower viscosity). This behavior is why our Martests factory produces a range of viscometers, including cone and plate viscometers and those with programmable speed profiles, because accurately characterizing non-Newtonian fluids often requires testing at various shear rates. This is a key selling point for purchasing managers whose clients deal with such materials.

Types of Non-Newtonian Behavior

The relationship between shear stress and shear rate (and thus viscosity) can vary:

| Behavior Type | Description | Common Examples | Viscosity Trend with Increasing Shear Rate/Stress |

|---|---|---|---|

| Shear-Thinning (Pseudoplastic) | Viscosity decreases as shear rate or shear stress increases. The fluid becomes "thinner" when stirred or forced to flow faster. | Ketchup, paint, blood, polymer solutions, creams | Decreases |

| Shear-Thickening (Dilatant) | Viscosity increases as shear rate or shear stress increases. The fluid becomes "thicker" when stirred or forced to flow faster. | Cornstarch-water mixture (oobleck), some industrial slurries | Increases |

| Bingham Plastic | Fluid requires a minimum shear stress (yield stress) to be overcome before it starts to flow like a liquid. Below this yield stress, it behaves like a solid. | Toothpaste, mayonnaise, drilling muds | Constant after yield stress is exceeded |

Why This Is Critical

Understanding non-Newtonian behavior is crucial because:

- Process Design: How do you pump paint if it thickens under stress, or design a mixer for a shear-thinning food product?

- Product Performance: How easily does a lotion spread? Will ink flow properly through a printer nozzle? Does a coating sag after application?

My customer Jacky, who sources various lab instruments and resells them in Italy with his own logo, often gets inquiries about measuring these complex fluids. Being able to explain these behaviors and provide the right Martests viscometer, like a cone and plate model which offers well-defined shear rates, is essential for his business and for his customers' success.

Conclusion

Viscosity quantifies a fluid's resistance to shear stress. This relationship is linear for Newtonian fluids but complex and variable for non-Newtonian fluids, impacting flow behavior.