Are your prints showing inconsistent color density, smudging, or poor detail resolution? These frustrating issues often stem from improper ink viscosity management, costing you time, materials, and customer satisfaction.

Ink viscosity is the measurement of an ink's resistance to flow, directly affecting how it transfers to substrates and ultimately determines print quality. Proper viscosity control ensures consistent color density, sharp detail reproduction, and appropriate drying times across all print runs.

When I visit printing facilities, the difference between operations with proper viscosity control and those without is immediately apparent. The former produces crisp, consistent prints while the latter struggles with variable quality. Let me share what I've learned about this critical yet often overlooked aspect of print production.

What Is Ink Viscosity and Why Does It Matter?

Printers often struggle with quality issues because they don't fully understand what viscosity is and why it's so fundamental to the printing process. This knowledge gap leads to costly trial-and-error approaches.

Ink viscosity is a fluid's internal resistance to flow under applied pressure. Measured in centipoise (cP) or cup seconds, it determines how ink flows through the printing system and onto the substrate. The right viscosity ensures proper ink transfer, adhesion, and penetration into the substrate.

Understanding ink viscosity requires looking beyond simple thickness to examine its behavior during the printing process. In my 15 years supplying measurement equipment to the printing industry, I've observed how this property affects every aspect of print quality:

The Science Behind Ink Flow

Viscosity is not merely about an ink being "thick" or "thin" – it's about flow behavior under specific conditions. This flow behavior directly impacts how ink transfers from plates, rollers, or screens onto the substrate, and subsequently how it sets on the surface.

| Viscosity Component | Description | Impact on Printing |

|---|---|---|

| Plastic Viscosity | Resistance to flow at high shear rates | Affects ink transfer from rollers/plates |

| Yield Value | Force needed to start ink flow | Influences dot gain and spread |

| Thixotropy | Time-dependent viscosity reduction under stress | Determines recovery time and prevents running/sagging |

| Tack | Stickiness/cohesion of ink | Affects ink splitting and transfer efficiency |

When consulting with a large packaging printer last year, we discovered their color inconsistency stemmed from misunderstanding these viscosity components. Their inks had appropriate "thickness" when measured at rest, but their thixotropic properties were inconsistent. This caused variable flow behavior during high-speed printing, resulting in uneven color density across the press run. After implementing proper viscosity testing that accounted for thixotropic behavior, they achieved remarkable consistency in their output.

How Does Temperature Affect Ink Viscosity?

Many printers underestimate how dramatically temperature fluctuations impact viscosity. Without accounting for this relationship, quality problems are inevitable, especially in facilities with variable environmental conditions.

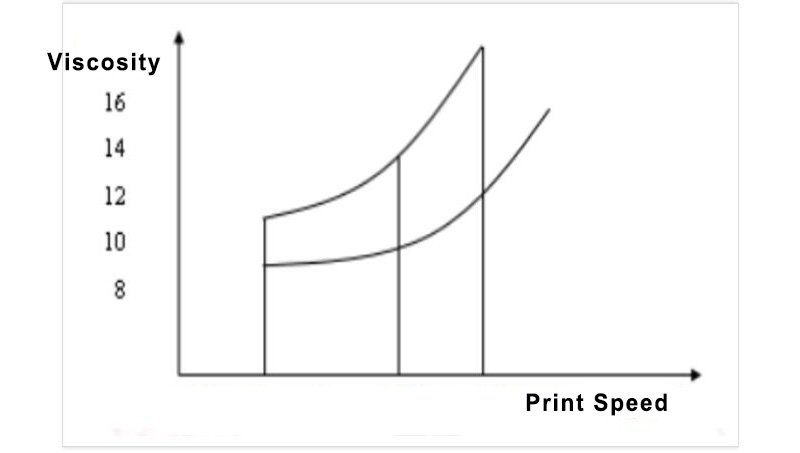

Temperature has an inverse relationship with ink viscosity—as temperature increases, viscosity decreases. Even small temperature variations of 5-10°C can change viscosity by 20-50%, significantly affecting ink flow, transfer properties, and ultimately print quality.

Temperature control is perhaps the most overlooked aspect of viscosity management in print shops. Let me share what I've learned about this critical relationship:

Managing the Temperature-Viscosity Relationship

In my work with printing operations across different climates, I've seen firsthand how temperature variations can undermine quality control efforts. The science behind this relationship is fascinating and essential for any printer to understand.

| Temperature Effect | Technical Explanation | Practical Implications |

|---|---|---|

| Molecular Movement | Higher temperatures increase molecular kinetic energy | Ink flows more readily through systems and screens |

| Solvent Evaporation | Temperature affects evaporation rates of carriers | Changes viscosity during press run |

| Pigment Dispersion | Heat can alter pigment-vehicle interactions | May affect color strength and stability |

| Rheological Recovery | Temperature affects thixotropic recovery time | Impacts set-off and print stack behavior |

| Seasonal Variations | Ambient temperature changes affect ink in storage | Requires seasonal viscosity adjustments |

I once worked with a printer in a facility without climate control who experienced dramatic quality differences between summer and winter production. Their solution was creating temperature-specific viscosity targets and implementing in-line temperature monitoring. This simple change reduced their quality rejections by over 30% and virtually eliminated seasonal color matching issues.

What's particularly important is establishing standard temperature measurement protocols alongside viscosity testing. Without standardized temperature conditions, viscosity measurements become meaningless for comparison purposes. Most professional print shops now maintain temperature-controlled ink rooms and conduct all viscosity measurements at a standard temperature (typically 25°C) to ensure meaningful data.

How Does Ink Viscosity Affect Print Quality?

Print defects that seem mysterious often have viscosity at their root. Identifying this connection can solve persistent quality problems that otherwise might be misattributed to equipment issues or operator error.

Optimal ink viscosity ensures proper ink transfer, accurate dot reproduction, color consistency, and appropriate drying time. Too high viscosity causes poor flow, weak colors, and dot gain issues. Too low viscosity leads to running, bleeding, strike-through, and drying problems.

The relationship between viscosity and print quality extends across all printing processes but manifests differently depending on the technique. Here's what I've observed working with various printing operations:

Viscosity's Multi-faceted Impact on Print Results

Every print quality attribute traces back to viscosity in some way. Understanding these connections helps printers make informed adjustments rather than guessing at solutions:

| Print Quality Attribute | Impact of High Viscosity | Impact of Low Viscosity | Optimal Control Approach |

|---|---|---|---|

| Color Density/Intensity | Inadequate ink transfer, weak colors | Excessive ink consumption, oversaturation | Regular density measurements correlated with viscosity |

| Detail Reproduction | Poor penetration into fine engraving, missing details | Excessive dot gain, blurred details | Microscopic examination of test patterns |

| Drying/Setting Time | Slow drying, set-off problems | Fast initial set but poor cure, blocking issues | Standardized drying tests at production speeds |

| Surface Appearance | Orange peel effect, poor leveling | Inadequate film thickness, poor opacity | Gloss measurements correlated with viscosity |

| Adhesion to Substrate | Inadequate penetration into substrate | Excessive penetration, strike-through | Standardized tape/rub tests |

| Registration Accuracy | Dimensional stability issues with paper | Dimensional stability issues with paper | Register mark verification |

During a consulting project with a security printer producing high-value documents, we discovered that seemingly random print defects appeared only during certain humidity conditions. The root cause was the interaction between paper moisture content and ink viscosity. By implementing humidity-specific viscosity targets, they eliminated these sporadic quality issues entirely.

What fascinates me most is how ink viscosity doesn't just affect visual print quality but also functional properties like durability, rub resistance, and chemical resistance. For example, in packaging printing, incorrect viscosity can lead to products that look perfect but fail scratch resistance tests or show poor resistance to household chemicals. This broader understanding of viscosity's impact helps printers deliver not just visually appealing but functionally superior products.

What Methods Are Used to Measure Ink Viscosity?

Choosing the wrong measurement method often leads to inconsistent results. Many printers don't realize that different viscosity measurement techniques are appropriate for different ink systems and applications.

Ink viscosity can be measured using flow cups (like Zahn, Ford, or DIN cups), rotational viscometers, falling ball viscometers, or inline viscometers. Each method offers different advantages in terms of accuracy, ease of use, and appropriateness for specific ink types.

After supplying measurement equipment to hundreds of printing operations, I've developed clear insights into which methods work best in different situations:

Selecting the Right Measurement Approach

The choice of viscosity measurement method significantly impacts your ability to control print quality effectively. Here's what I recommend based on extensive field experience:

| Measurement Method | Working Principle | Best Applications | Limitations | Accuracy Level |

|---|---|---|---|---|

| Flow Cups (Zahn, Ford, DIN) | Timed gravity flow through calibrated orifice | Press-side quick checks, solvent-based inks | Less accurate for thixotropic inks, operator-dependent | ±5-10% |

| Rotational Viscometers | Measuring torque required to rotate spindle in fluid | Laboratory settings, quality control, high-viscosity inks | Not ideal for press-side, requires careful sample handling | ±1-3% |

| Falling Ball Viscometers | Time for ball to fall through fluid | Transparent fluids, laboratory settings | Not suitable for opaque inks or press-side | ±2-5% |

| Inline Viscometers | Continuous measurement in ink circulation system | Automated press systems, long runs requiring consistency | Initial investment cost, requires integration with systems | ±1-2% |

| Vibration Viscometers | Measuring damping of vibration in fluid | Automated systems, continuous monitoring | Higher cost, requires technical expertise to maintain | ±0.5-2% |

I recently helped a label printer who was experiencing inconsistent quality despite using flow cups to check viscosity. After analyzing their process, we discovered their highly thixotropic UV inks weren't accurately measured by flow cups. Switching to a rotational viscometer that could measure at different shear rates solved their problem, improving their color consistency dramatically.

What's particularly important is matching the measurement method to your specific inks and printing process. For example, screen printing typically uses higher-viscosity inks than flexography, requiring different measurement approaches. Similarly, quick-setting UV inks need different measurement protocols than slower-drying conventional inks.

The measurement frequency is equally important as the method itself. In high-volume operations, I've seen best results when measurements are taken at regular intervals determined by production volume rather than time—for example, every 5,000 impressions rather than every hour.

Conclusion

Ink viscosity is a fundamental factor affecting print quality across all printing processes. By understanding viscosity behavior, implementing appropriate measurement techniques, and controlling variables like temperature, printers can achieve consistent, high-quality results while reducing waste and production costs.