Working with liquids that flow too easily can be challenging. This can cause spills, waste, and control issues in your production line, leading to inconsistent products and higher costs.

Low viscosity liquids are fluids that flow very easily with little internal resistance, like water or solvents. Understanding their properties is crucial for industries ranging from inkjet printing to pharmaceuticals for ensuring process control and product quality.

At Martests, we know that handling "thin" liquids is just as important as managing thick ones. My customers, from large distributors in Europe to specialized buyers in South America, often need to measure and control these fluids precisely. This guide will walk you through the key aspects of low viscosity liquids. We'll cover what they are, what factors affect them, and how you can master their use in your applications. This knowledge will help you improve efficiency and create better products.

What Exactly is Viscosity?

Are you trying to describe a liquid's thickness but lack the right term? This makes technical communication with suppliers and customers difficult and can lead to misunderstandings.

Viscosity is the scientific measure of a fluid's internal friction, or its resistance to flow. A high viscosity means a fluid is thick, like honey. A low viscosity means a fluid is thin and flows easily, like water.

Think of viscosity as the "stickiness" inside a liquid. In a high-viscosity liquid like honey, the molecules are strongly attracted to each other, making them slow to move. In a low-viscosity liquid like water, the molecules move past each other with very little friction. We measure viscosity in units like centipoise (cP). For reference, water at room temperature has a viscosity of about 1 cP. For my B2B customers, like Jacky in Italy who rebrands our viscometers, having precise viscosity specifications is non-negotiable. It is the language of quality control for any liquid product. Understanding this basic concept is the first step toward mastering your fluid handling processes.

What Factors Change a Liquid's Viscosity?

Does your liquid behave differently on a hot day versus a cold one? This inconsistency can ruin a process and lead to batch failures if you don't know the cause.

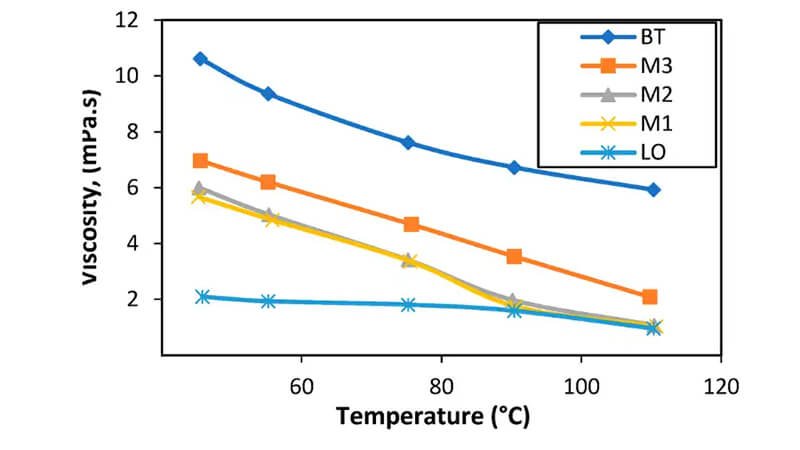

The main factors affecting viscosity are temperature, pressure, and shear rate. For most common applications, temperature is the most significant factor, as a small temperature change can cause a large change in viscosity.

Controlling a liquid's viscosity means you must control the factors that influence it. When I work with clients, we always start by identifying the most critical variables in their specific process.

Temperature

This is the biggest factor for most liquids. As temperature increases, viscosity almost always decreases. The liquid becomes "thinner." A cold engine oil is very thick, but it thins out as the engine warms up. This is why temperature control is essential when measuring viscosity.

Pressure

For most liquids, increasing pressure slightly increases viscosity. The molecules are squeezed closer together, increasing friction. However, this effect is usually small unless you are working with extremely high pressures, like in deep-sea applications or hydraulic systems.

Shear Rate

This refers to the force applied to the liquid, like stirring or pumping. For some liquids (non-Newtonian), viscosity changes with shear rate. For example, paint thins out as you brush it on the wall.

| Factor | Effect on Viscosity | Common Example |

|---|---|---|

| Temperature | Increases → Viscosity Decreases | Warming up honey makes it flow faster. |

| Pressure | Increases → Viscosity Increases (Slightly) | High-pressure hydraulic fluid. |

| Shear Rate | Can Increase or Decrease Viscosity | Stirring paint makes it thinner. |

What Exactly Are Low Viscosity Liquids?

Is the term "thin liquid" too vague for your technical needs? You need a clear, scientific definition to maintain consistent quality standards and select the right equipment for your lab.

Low viscosity liquids are fluids with very little resistance to flow, generally defined as having a viscosity below 100 centipoise (cP). Common examples include water, alcohol, solvents, gasoline, and milk.

When we talk about low viscosity, we are referring to a specific range on the viscosity scale. Water, at 1 cP, is the classic benchmark. Anything that flows similarly to or slightly thicker than water falls into this category. This is a huge group of materials that are essential to countless industries. Here are some everyday and industrial examples:

- Water: ~1 cP

- Milk: ~3 cP

- Acetone (Nail Polish Remover): ~0.3 cP

- Ethanol (Alcohol): ~1.2 cP

- Gasoline: ~0.6 cP

- Mercury: ~1.5 cP

- Light Machine Oils: 10-50 cP

Understanding this classification is important. It helps you choose the right rotational viscometer from our factory, ensuring the spindle and speed settings are sensitive enough to get accurate readings for these free-flowing substances.

Where Are Low Viscosity Liquids Used?

Do you think only thick, heavy materials matter in industry? In reality, many critical processes rely entirely on the unique properties of thin, free-flowing liquids to function properly.

Low viscosity liquids are essential across many sectors. They are used as solvents in cleaning and coatings, as fuels and lubricants in engines, as the base for beverages, and for injectable drugs in pharmaceuticals.

The ability of these liquids to flow easily, penetrate small spaces, and transfer heat makes them incredibly versatile. My customers use our viscometers to control quality in all these areas.

Solvents and Cleaning Agents

Liquids like acetone and isopropyl alcohol have very low viscosity, allowing them to penetrate tiny cracks and dissolve contaminants effectively, making them perfect for cleaning electronics or preparing surfaces.

Inks and Coatings

For spray painting or inkjet printing, the ink or paint must have a low viscosity to be atomized into fine droplets and form a smooth, even layer.

Fuels and Lubricants

Gasoline and diesel must be low viscosity to be easily pumped and injected into an engine's cylinders. Some lubricants are also very thin to reduce drag in high-speed applications.

Food and Beverage

The viscosity of liquids like milk, juice, and soft drinks is a key quality parameter. It affects everything from the "mouthfeel" to the efficiency of filling bottles on a production line.

Pharmaceuticals

Many medicines are delivered as injections. These solutions must have a low, controlled viscosity to be easily drawn into a syringe and injected with minimal pain.

What Are the Advantages of Using Low Viscosity Liquids?

Are you struggling with high energy costs for pumping and mixing materials? Using a low viscosity fluid could be the simple, effective solution you have been looking for.

The primary advantages of low viscosity liquids include easy pumping with low energy use, excellent wetting and penetration into small spaces, rapid mixing and blending, and efficient heat transfer capabilities.

Working with low viscosity liquids brings many process benefits. For my customers who are distributors, highlighting these advantages helps them sell to a wider range of industries. Here are some of the key benefits:

- Easy Pumping: Less energy is required to move them through pipes.

- Low Energy Mixing: They blend together quickly and with minimal power.

- Excellent Penetration: They can easily seep into porous materials or small gaps.

- Good Wetting: They spread out evenly over surfaces.

- Easy Filtration: They pass through filters quickly and with less pressure.

- Effective Heat Transfer: They are great for cooling and heating applications because they circulate easily.

- Easy to Spray/Atomize: They form fine mists, which is essential for applications like spray coating and fuel injection.

What Are the Disadvantages of Using Low Viscosity Liquids?

Are you dealing with constant spills, leaks, and inconsistent coatings? The problem might not be your process but the inherent challenges of the low viscosity liquid you are using.

The main disadvantages include a high tendency to leak from seals, difficulty in forming stable coatings on vertical surfaces, splashing during handling, and providing poor lubrication under high-load conditions.

While they have many benefits, thin liquids also present a unique set of challenges that require careful engineering and handling. Ignoring these can lead to safety hazards and quality issues.

- Prone to Leaking: They can easily escape through tiny gaps in seals and fittings.

- Splashing and Misting: They can easily splash or create aerosols, which can be a safety or contamination risk.

- Poor Suspension: They cannot keep solid particles suspended for long; particles tend to settle out quickly.

- Difficult to Contain: Spills spread very quickly and can be hard to clean up.

- Higher Evaporation Rate: Many low viscosity liquids are volatile and evaporate quickly.

- Poor Film Build: It is difficult to apply a thick, single-coat layer on a surface.

- Poor Lubrication Under Pressure: They can be squeezed out from between surfaces, leading to wear.

Why is Choosing the Right Low Viscosity Liquid So Important?

Did you choose a liquid based only on its price? This common mistake can lead to a cascade of problems, from equipment failure and production halts to serious safety incidents.

Choosing the correct low viscosity liquid is critical for ensuring process efficiency, final product quality, and operational safety. A wrong choice can lead to equipment damage, inconsistent batches, and dangerous working conditions.

I always emphasize this point to my clients. The liquid is not just an ingredient; it is an integral part of your entire system. Making the right choice from the start saves enormous amounts of time and money.

A correct choice leads to:

- Optimized Performance: Your equipment runs smoothly and efficiently.

- Consistent Product Quality: Every batch meets the required specifications.

- Reduced Wear and Tear: The right fluid protects pumps and machinery.

- Enhanced Safety: Reduces risks of leaks, spills, or hazardous fumes.

- Lower Operational Costs: Less energy use, less waste, and less maintenance.

An incorrect choice can cause:

- Catastrophic Equipment Failure: Using a liquid that provides poor lubrication can destroy pumps and gears.

- Product Rejection: If a solvent evaporates too quickly or a coating runs, the entire batch may be lost.

- Safety Hazards: Using a flammable liquid with a low flash point in a hot environment can lead to fires.

How Do You Adapt to Other Changes in Liquid Viscosity?

Is your viscosity inconsistent even when temperature and pressure are controlled? Other hidden factors might be silently degrading your liquid and ruining your results.

Besides temperature, pressure, and shear, viscosity is affected by aging, contamination, composition changes, evaporation of solvents, dissolved gases, and degradation of the liquid's molecular structure over time.

A liquid's viscosity is not always stable. As a manufacturer, we at Martests design our viscometers to be sensitive enough to detect these subtle changes, which are crucial for long-term quality control. You must be aware of these other factors:

- Aging/Shelf Life: Over time, the chemical structure of a liquid can change, altering its viscosity.

- Contamination: Even a small amount of a different liquid or solid can dramatically change viscosity.

- Solute Concentration: In solutions, adding more dissolved material (like sugar in water) will increase viscosity.

- Evaporation: If a volatile solvent evaporates from a mixture, the remaining liquid will become more concentrated and thicker.

- Dissolved Gases: Bubbles of dissolved gas coming out of the solution can interfere with flow and measurement.

- Molecular Weight Degradation: In polymers or oils, long molecular chains can break down due to stress or heat, permanently lowering the viscosity.

Conclusion

Mastering low viscosity liquids is key. Choosing the right one and controlling influencing factors ensures process efficiency, product quality, and overall safety for your business.