You need to understand how your materials flow, but your current methods are inaccurate or waste precious samples. This leads to inconsistent product quality and higher development costs.

A cone and plate rheometer is a specialized lab instrument that measures a fluid's flow properties. It uses a rotating cone and a stationary plate to create a uniform shear rate, making it ideal for precisely analyzing non-Newtonian fluids with very small sample volumes.

At Martests, we know that precision is everything. My clients, who are distributors of scientific instruments across Europe and Southeast Asia, always ask for tools that deliver reliable data. The cone and plate rheometer is one of those key instruments. It helps manufacturers develop better products, from smoother paints to creamier yogurts. In this post, I’ll explain what this device is, how it works, and why it might be the perfect tool for your quality control or research needs. Let's dive into the details.

What is rheology and why is a cone and plate rheometer important?

You hear the term "rheology" but are not sure how it applies to your products. This uncertainty means you are just guessing about the flow behavior of your paints or sauces.

Rheology is the science of how materials flow and deform. A cone and plate rheometer is a vital tool in this field because it provides highly accurate and repeatable data, especially for non-Newtonian fluids, by using a uniform shear rate and a small sample size.

Rheology helps us understand why some fluids, like water, flow consistently, while others, like ketchup or polymer solutions, change their viscosity when a force is applied. These are called non-Newtonian fluids, and they are common in many industries. To test these materials, we use different types of rheometers.

Common Rheometer Geometries

While several instruments can measure viscosity, they are suited for different tasks. The cone and plate system has unique advantages that make it a top choice for many applications.

| Rheometer Type | Key Advantage | Best For |

|---|---|---|

| Capillary Rheometer | High shear rates | Polymer melts |

| Coaxial Cylinder | Good for unstable samples | Suspensions, emulsions |

| Parallel Plate | Versatile, adjustable gap | Pastes, solids, curing materials |

| Cone and Plate | Uniform shear rate | Low-viscosity liquids, solutions |

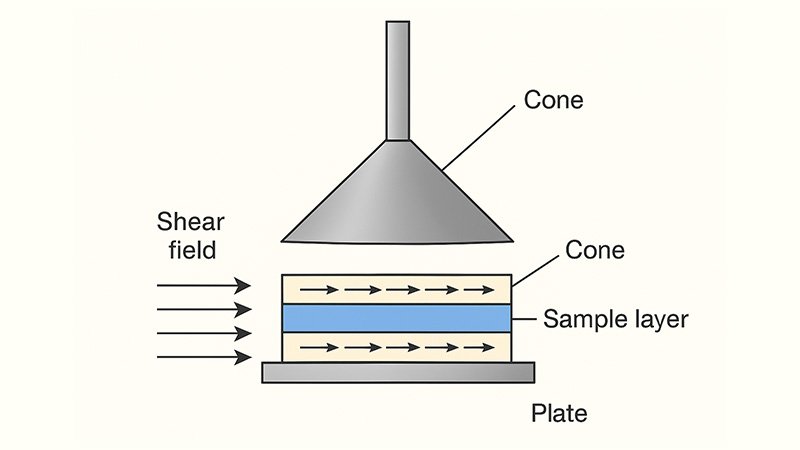

As you can see, the standout feature of the cone and plate rheometer is its ability to create a perfectly uniform shear field. This means every part of the sample is tested under the exact same conditions, which leads to cleaner, more reliable data.

What are the main parts of a cone and plate rheometer?

You look at a rheometer and see a complex machine. Not knowing what each part does can make you hesitant to use it effectively, fearing you might get bad data.

A cone and plate rheometer consists of five main parts: a stationary flat plate, a rotating cone, a temperature control unit, a drive motor, and a torque sensor. Together, these components apply and measure shear on a sample.

Understanding the function of each component demystifies the instrument and helps you appreciate how it achieves such high precision. I often walk my customers, like Jacky in Italy, through these parts to build their confidence in the technology.

The Core Components

- Rotating Cone and Fixed Plate: The bottom part is a flat, stationary plate where the sample is placed. Above it is a cone with a very slight angle (usually 1-4 degrees) that is driven by a motor. The tiny gap between them holds the sample.

- Drive and Detection System: The "muscle" is a precision motor that rotates the cone at a very specific angular velocity. The "brain" is a sensitive torque sensor that measures the rotational force, or resistance, that the fluid exerts on the cone.

- Temperature Control System: A fluid's viscosity is highly dependent on its temperature. To get accurate results, a temperature unit, often a Peltier system or a circulating fluid bath, keeps the sample at a constant, precise temperature throughout the test. At Martests, we use top-quality components to ensure this temperature stability.

How does a cone and plate rheometer actually measure viscosity?

You know the parts, but the link between a spinning cone and a final viscosity number seems like magic. How does the machine convert motion and resistance into a useful data point?

The rheometer works by applying a controlled shear deformation. The rotating cone creates a uniform shear rate across the sample. The system measures the torque (resistance) needed to maintain that rotation, and from these two values, it calculates viscosity.

The working principle is based on a few straightforward physics equations. The unique geometry of the cone and plate is what makes these calculations so direct and accurate.

From Rotation to a Viscosity Value

The process can be broken down into three steps:

- Determining Shear Rate (γ̇): The shear rate is how fast the material is being deformed. In this system, it is calculated from the cone's rotational speed (ω) and its angle (θ). Because the gap increases linearly from the center, the shear rate is constant everywhere in the sample. The formula is:

γ̇ = ω / θ - Determining Shear Stress (τ): The shear stress is the force per unit area required to deform the fluid. It is calculated from the torque (M) measured by the sensor and the radius of the cone (R). More resistance from the fluid means a higher torque and thus a higher shear stress. The formula is:

τ = 3M / (2πR³) - Calculating Viscosity (η): Viscosity is defined as shear stress divided by shear rate. The rheometer simply takes the value from step 2 and divides it by the value from step 1 to get the apparent viscosity.

η = τ / γ̇

This clear relationship between the machine's actions and the final result is what makes the data so trustworthy.

What makes the cone and plate rheometer so advantageous?

You are comparing different types of rheometers and are not sure why you should choose a cone and plate system. They all seem to do a similar job on the surface.

The cone and plate rheometer offers four key advantages: a perfectly uniform shear rate for accurate data, a very small sample volume requirement, high sensitivity for low-viscosity fluids, and suitability for steady-state measurements.

| Benefit | Explanation |

|---|---|

| Uniform Shear Rate | Ensures every particle of the fluid experiences the same shear conditions, yielding a single, precise viscosity value. |

| Small Sample Volume | Requires only a few hundred microliters, ideal for costly or rare materials like pharmaceuticals or biological fluids. |

| High Sensitivity | Accurately measures very low resistance forces, perfect for thin, low-viscosity liquids such as milk, blood, solvents. |

| Excellent for Steady-State Measurement | Ideal for tests at constant shear rate or for generating full viscosity curves through shear rate ramps. |

These benefits make it the preferred instrument in many high-stakes industries where precision and efficiency are paramount. Let's explore each one.

- Uniform Shear Rate: This is the most significant advantage. Unlike other geometries where shear can vary, here every particle of the fluid is tested under the same conditions. This gives you a single, unambiguous viscosity value at a specific shear rate.

- Small Sample Volume: The instrument typically requires only a few hundred microliters of fluid. This is a huge benefit when working with expensive or rare materials, such as pharmaceuticals, novel polymers, or biological fluids.

- High Sensitivity: The design allows for the accurate measurement of very low resistance forces. This makes it perfect for analyzing thin, low-viscosity liquids like milk, blood, solvents, and inks, which might not register properly on less sensitive systems.

- Excellent for Steady-State Measurement: This geometry is ideal for performing tests where you hold the shear rate constant to see how viscosity changes over time or ramp the shear rate up and down to generate a complete viscosity curve.

Where is the cone and plate rheometer used in practice?

The theory sounds good, but you're wondering if this instrument is actually relevant to your industry. You want to know if it solves real-world problems for your products.

The cone and plate rheometer is a workhorse in many industries. It is used in food science for texture, in pharma for drug delivery, in coatings for application performance, and in polymers for processability.

My customers are distributors who sell to a wide range of manufacturers. They tell me the cone and plate rheometer is indispensable in many fields.

- Food Industry: It is used to study and control the texture and "mouthfeel" of products like chocolate, yogurt, sauces, and dressings. The flow properties directly relate to consumer perception of quality.

- Pharmaceuticals and Biomedicine: This instrument is vital for analyzing the flow of blood, developing injectable drugs, and ensuring that ointments and creams spread correctly and feel pleasant on the skin.

- Coatings and Inks: It helps formulators predict how a paint will behave. Will it level smoothly without leaving brush marks? Will it be too thin and drip? For inks, it ensures proper flow through a printer head.

- Polymers and Composites: For plastic manufacturers, understanding the flow properties of a polymer melt is crucial for processes like injection molding and extrusion. The rheometer data helps optimize production and prevent defects.

Are there any downsides to using a cone and plate rheometer?

It seems like the perfect tool, but you're rightly worried about potential drawbacks. Ignoring an instrument's limitations can lead to inaccurate results and frustration.

Yes, there are limitations. A cone and plate rheometer is not suitable for materials with large particles, can be sensitive to sample loading and edge effects, and can struggle at very high shear rates where the sample may be ejected.

| Limitation | Explanation |

|---|---|

| Not for Large Particles or Fibers | The cone–plate gap is very narrow. Large particles, aggregates, or fibers can get trapped, causing false readings or damage. |

| Sensitive to Edge Effects | Sample edges are exposed to air, leading to drying or evaporation during long tests. This alters properties and skews results. |

| Difficulty at High Shear Rates | At very high speeds, centrifugal force can eject liquid (edge fracture), limiting the maximum measurable shear rate. |

Being aware of these limitations is key to getting good results. It's about using the right tool for the right job.

- Not for Large Particles or Fibers: The gap between the cone and plate is very narrow. If your sample contains large suspended particles, aggregates, or fibers (like a chunky salsa or a fiber-reinforced polymer), they will get stuck. This will give false readings and can even damage the instrument.

- Sensitive to Edge Effects: Because the sample is exposed to air at its edge, it can be prone to drying or solvent evaporation during a long test. This changes the sample's properties and can skew the results. Careful and precise sample loading is required to minimize this.

- Difficulty at High Shear Rates: If the cone spins too fast, centrifugal force can fling the liquid out of the gap. This phenomenon, known as edge fracture, sets a practical upper limit on the shear rates you can accurately measure with this geometry.

Conclusion

The cone and plate rheometer is a powerful and precise tool for analyzing fluid flow. Understanding its principles, advantages, and limitations helps you get reliable data for quality control and innovation.