Need precise viscosity data but find other methods complex or error-prone? Inaccurate results can ruin product quality, costing you money and your reputation with customers.

The Ubbelohde viscometer is a highly accurate glass capillary instrument used to measure the kinematic viscosity of transparent liquids. It works by measuring the time it takes for a fixed volume of fluid to flow under gravity through a calibrated capillary tube.

Even though my factory, Martests, specializes in modern rotational viscometers, I have deep respect for the classics. My customers, distributors like Jacky in Italy, often ask me to compare different viscosity measurement methods. The Ubbelohde viscometer is a name that always comes up, especially for R&D and polymer science. It's known as a gold standard for its precision and reliability. To be a true expert, you need to understand all the important tools of the trade, not just the ones you sell. So, let's dive into what makes this instrument so special.

What is an Ubbelohde Viscometer and Why is it Important?

You hear about Ubbelohde viscometers for polymer testing but aren't sure why they're special. This knowledge gap makes it hard to advise your own clients effectively.

The Ubbelohde viscometer is a suspended-level capillary viscometer. Its key feature is that the measurement is independent of the sample volume, which eliminates a major source of error found in older capillary viscometers. This makes it highly precise for dilute solutions.

When a customer needs the absolute highest precision for a Newtonian fluid, the conversation often turns to capillary viscometry. And in that world, the Ubbelohde design is king. It represents a significant step forward in measurement science.

Definition and Basic Concept

An Ubbelohde viscometer is a U-shaped glass instrument designed to measure kinematic viscosity. Kinematic viscosity is a measure of a fluid's resistance to flow under the influence of gravity. The core idea is simple: time how long it takes for a liquid to pass through a very thin tube (a capillary). The genius of the Ubbelohde design is its "suspended-level" principle. A third tube vents the lower bulb to the atmosphere. This means the pressure driving the flow depends only on the height of the liquid column, not the total volume of sample in the instrument. This clever design removes a big variable and makes the results much more repeatable.

Historical Development

The instrument was invented by the German chemist Leo Ubbelohde. Before his design, viscometers like the Ostwald viscometer were common. But they had a flaw: the driving pressure depended on how much sample you put in. This made it difficult to get consistent results, especially when making dilutions for polymer analysis. Ubbelohde's addition of the third venting tube solved this problem completely. It was a simple but brilliant innovation that made capillary viscometry much more reliable and accurate, securing its place in laboratories worldwide.

How Does an Ubbelohde Viscometer Actually Work?

The glass tube looks confusing, and you don't understand how it measures anything. This makes it hard to trust the results or explain the process to others.

It works by timing a liquid's flow between two marked points in a capillary under gravity. Its unique third tube allows the pressure head to be independent of the initial sample volume, ensuring consistent and accurate kinematic viscosity measurements.

The first time I saw one in a university lab, I was also a bit intimidated by all the bulbs and tubes. But the principle is very elegant. Let me break it down into simple parts. It's all about gravity, time, and a very precise piece of glass.

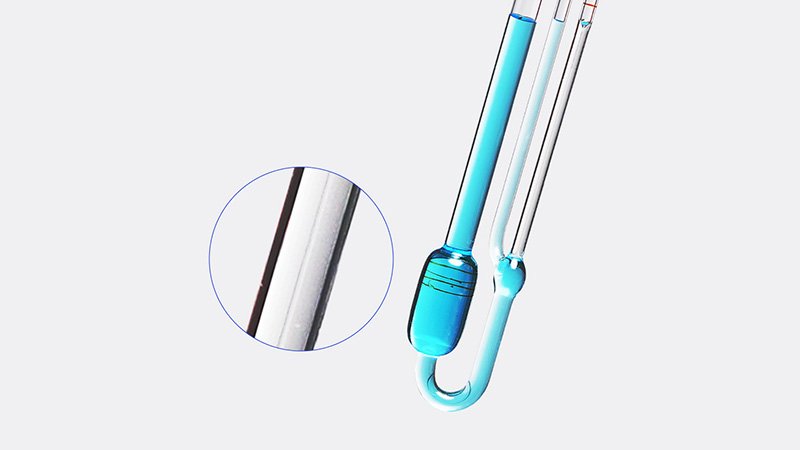

Basic Structure and Components

The viscometer might look complex, but it has a few key parts that work together. Understanding them makes the process clear.

| Component | Function |

|---|---|

| Filling Tube (Tube 1) | The widest tube, used to introduce the sample liquid into the viscometer. |

| Measuring Tube (Tube 2) | Contains the capillary and two calibration marks (A and B) for timing the flow. |

| Venting Tube (Tube 3) | The unique Ubbelohde feature. It connects the bulb below the capillary to the atmosphere. |

| Bulbs | Act as reservoirs to hold the liquid and ensure a consistent starting and ending point for measurement. |

Flow Mechanism and Measuring Principle

The measurement process is a careful, timed sequence. First, you pour the sample into the filling tube. Then, you place the viscometer in a constant temperature bath until the sample reaches thermal equilibrium. This is critical because viscosity is very sensitive to temperature. Next, you close the venting tube and apply suction to the measuring tube, drawing the liquid up past the top mark. Finally, you release the suction and open the venting tube. The liquid starts to fall under gravity. You use a stopwatch to measure the exact time it takes for the liquid's meniscus to pass from the upper mark to the lower mark. This time is your key data point.

Kinematic Viscosity Calculation

The best part is how simple the calculation is. The kinematic viscosity (ν) is found using a straightforward formula:

ν = K * t

Here, t is the flow time you just measured in seconds. K is the "viscometer constant." This constant is a specific value for each individual viscometer, determined during its calibration. It accounts for the exact geometry of the capillary. So, to find the viscosity, you just multiply your measured time by this constant.

What Types and Specifications of Ubbelohde Viscometers Exist?

You need to order a viscometer but see many different sizes and types. Choosing the wrong one means your measurements will be inaccurate or impossible to perform.

Ubbelohde viscometers come in various sizes, each with a specific "viscometer constant" (K). This constant corresponds to a particular viscosity range. Choosing the right size ensures the flow time is within the optimal range (e.g., over 200 seconds) for accuracy.

Just like you can't use a single wrench for all bolts, you can't use a single Ubbelohde for all liquids. When my customers ask about this, I explain that choosing the right size is the most important step for getting good data. The goal is to get a flow time that is long enough to minimize timing errors.

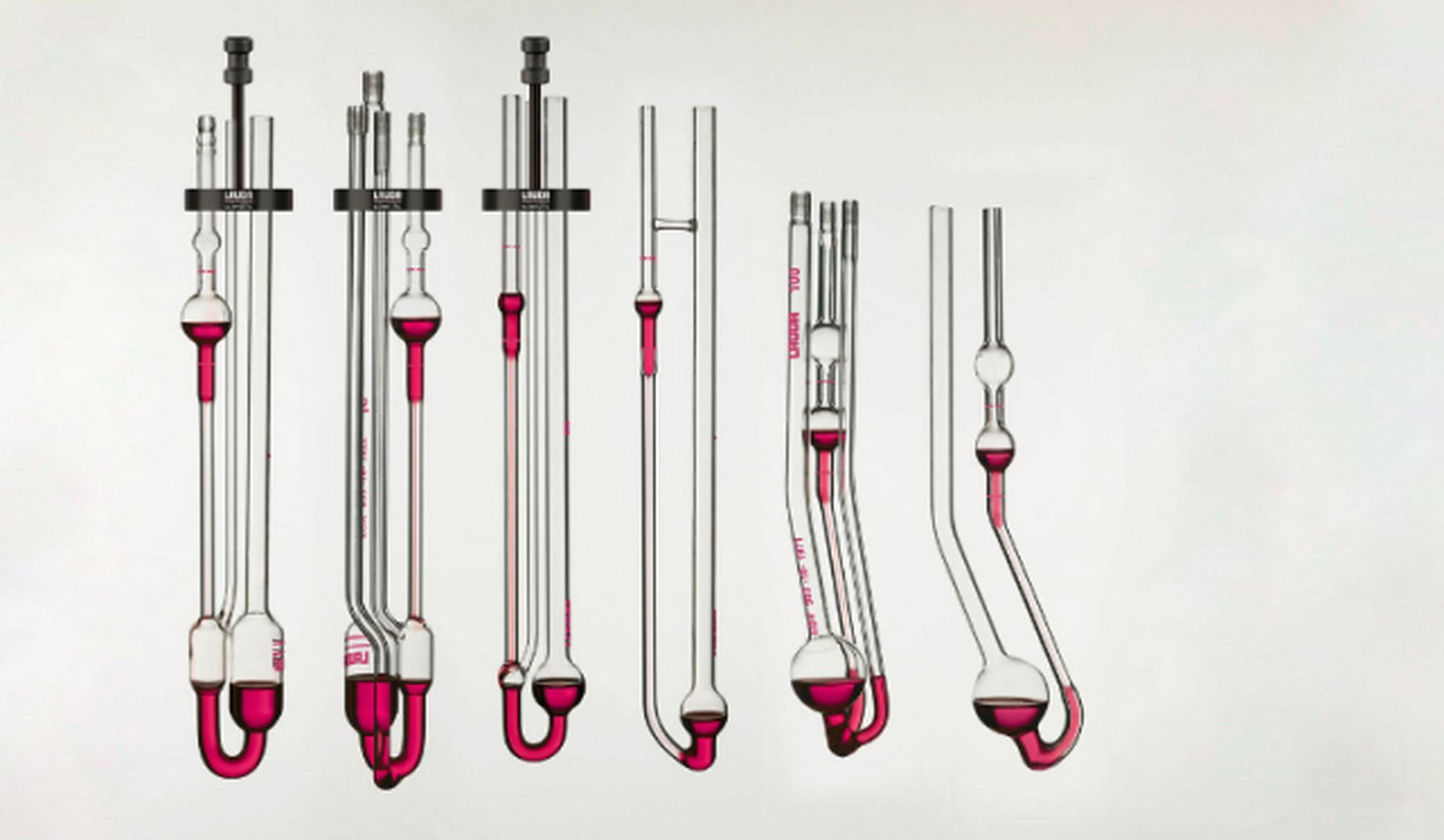

Standard Types and Sizes

Ubbelohde viscometers are not one-size-fits-all. They are manufactured in a series of standardized sizes, often designated by numbers like 0, 0C, 1, 1C, and so on. Each size has a capillary with a different diameter. A smaller size number means a narrower capillary, which is suitable for low-viscosity fluids. A larger size number means a wider capillary for more viscous fluids. This range ensures that you can find a viscometer that gives you a reasonable flow time for your specific sample.

Viscometer Constants

As I mentioned, each viscometer has its own unique constant, K. This constant is precisely determined by the manufacturer or a calibration lab. The relationship between size and constant is direct.

| Size (Example) | Approx. Constant (K) | Typical Viscosity Range (cSt) |

|---|---|---|

| 0 | 0.001 | 0.3 - 1 |

| 1 | 0.01 | 2 - 10 |

| 2 | 0.1 | 20 - 100 |

| 3 | 1.0 | 200 - 1000 |

You must choose a size where your expected viscosity results in a flow time that is long enough (usually >200 seconds) to make the error from starting and stopping the stopwatch negligible.

Temperature Range and Measurement Range

Ubbelohde viscometers are typically made from borosilicate glass. This material is great because it is chemically resistant and can handle a very wide range of temperatures, from well below freezing to over 100°C. However, the key is not the range but the control. The measurement must be done in a transparent, constant-temperature bath that can hold the temperature stable to within ±0.01°C for the most precise work. The measurement range of a specific viscometer is determined by its size and constant, as shown in the table above.

In Which Fields Are Ubbelohde Viscometers Used?

You see this is a precise tool, but you're not sure where it's actually applied. Understanding the applications helps you identify potential customers and their specific needs.

Ubbelohde viscometers are essential in applications requiring high-precision kinematic viscosity data, especially for polymer solutions, fuels, oils, and in pharmaceutical and academic research for fluid characterization.

When I talk to distributors, I always emphasize connecting the tool to the job. The Ubbelohde isn't for measuring the viscosity of thick paint or ketchup; that's what my rotational viscometers are for. This tool has its own specific, high-value applications.

Polymer Solutions Analysis

This is the classic application. Scientists use Ubbelohde viscometers to measure the viscosity of dilute polymer solutions. By measuring viscosity at different concentrations and extrapolating to zero concentration, they can determine the "intrinsic viscosity." This value is directly related to the polymer's molecular weight, which is a critical quality parameter. This method is fundamental in polymer chemistry R&D and quality control.

Oil Industry Applications

In the petroleum industry, the kinematic viscosity of fuels and lubricating oils is a vital specification. It affects engine performance, fuel atomization, and lubrication efficiency. The Ubbelohde viscometer is used to perform standardized tests (like ASTM D445) to ensure that products like diesel fuel, jet fuel, and engine oils meet their required viscosity grades at specific temperatures (e.g., 40°C and 100°C).

Pharmaceutical and Academic Research

In pharmaceutical development, the viscosity of liquid formulations can affect everything from manufacturability to drug delivery. In academic research, the Ubbelohde is a fundamental tool for studying fluid dynamics, characterizing new liquids, and validating theoretical models. Its high precision makes it perfect for generating reliable data for scientific publications.

What Are the Main Advantages of Using an Ubbelohde Viscometer?

You need to justify using this method over faster, more automated ones. Knowing its key advantages helps you explain its value to quality managers or lab technicians.

The primary advantages are its exceptional accuracy and reproducibility, thanks to the suspended-level design. It is also cost-effective and durable, providing a long service life with proper care, making it a staple in calibration and research labs.

While I manufacture electronic viscometers, I am the first to admit the strengths of this classic design. For certain tasks, its elegant simplicity is a huge advantage. It doesn't have software that can glitch or sensors that can drift. It's based on physics.

High Accuracy and Precision

This is its number one selling point. Because the measurement is independent of the sample volume and relies on a simple time measurement, it can achieve extremely high precision. When operated correctly in a controlled temperature bath, the results can be reproducible to within a fraction of a percent. This is why it is often used as a reference standard to calibrate other types of viscometers.

Temperature Control and Reproducibility

The design requires the use of a transparent, constant-temperature bath. While this sounds like an extra step, it's actually an advantage. It forces the user to achieve excellent temperature control, which is the most important factor for accurate viscosity measurement. This rigorous control, combined with the suspended-level principle, leads to outstanding reproducibility. You can be confident that a measurement taken today will be the same as one taken a month from now.

Cost-Effectiveness and Durability

A glass Ubbelohde viscometer is relatively inexpensive compared to a high-end electronic rheometer. It contains no moving parts or electronics that can fail. As long as you don't break the glass, it can last for decades. This makes it a very cost-effective solution for labs that need high-quality kinematic viscosity data but may not have the budget for more complex equipment.

How Do You Operate an Ubbelohde Viscometer Correctly?

You have the instrument, but you're worried about making mistakes during operation. Following a clear set of guidelines is essential for getting accurate and repeatable results.

Proper operation involves meticulous sample preparation and cleaning, precise temperature control in a water bath, and careful timing of the fluid's flow between the two calibration marks. Following the steps exactly is crucial for accuracy.

I always tell people that with a manual instrument like this, the operator is part of the measurement system. Your technique matters. A little bit of training and a lot of care are all you need to get fantastic results.

Sample Preparation and Loading

First, ensure your sample is free of any bubbles or solid particles, as these can disrupt the flow in the capillary. You might need to filter it. Then, carefully pour the correct amount of sample into the filling tube (Tube 1). While the measurement is independent of volume, you still need enough sample to perform the measurement.

Temperature Control and Measurement

This is the most critical part.

- Mount: Secure the viscometer vertically in a constant-temperature bath.

- Equilibrate: Wait at least 15-20 minutes for the sample to reach the bath's temperature.

- Load: Place your finger over the venting tube (Tube 3) and use a suction bulb on the measuring tube (Tube 2) to draw the liquid up past the top timing mark.

- Flow: Release the suction and immediately remove your finger from the venting tube. The liquid will begin to flow down the capillary.

- Time: Start your stopwatch the moment the liquid meniscus crosses the upper timing mark and stop it the moment it crosses the lower mark.

- Repeat: Perform at least three measurements. They should agree closely. Use the average time for your calculation.

Cleaning and Maintenance

Proper cleaning is essential for good results. After use, you must clean the viscometer thoroughly with appropriate solvents to remove all traces of the sample. Then, rinse with a volatile solvent (like acetone) and dry with clean, filtered air. Any residue left inside will affect the next measurement.

How Should You Calibrate and Maintain This Instrument?

Your viscometer has been in use for a while, and you're not sure if it's still accurate. Regular calibration and proper maintenance are essential for ensuring trustworthy results over time.

Calibration involves measuring the flow time of a certified standard fluid with a known viscosity at a specific temperature. This allows you to verify or determine the viscometer's constant (K). Regular cleaning and proper storage are key maintenance steps.

In my factory, calibration is everything. We can't ship a single rotational viscometer without verifying its accuracy. The same principle applies here. An uncalibrated instrument gives you a number, but you can't call it a measurement.

Calibration Procedures

To calibrate an Ubbelohde viscometer, you need a certified viscosity standard fluid. These are special oils with a precisely known kinematic viscosity at a specific temperature. You perform a measurement with this standard fluid just as you would with a sample. Since you know the viscosity (ν) and you measure the time (t), you can calculate the viscometer constant (K) using the formula: K = ν / t. It's recommended to perform this check periodically, especially if the viscometer is used heavily or if you suspect it has been damaged.

Regular Maintenance and Troubleshooting

Maintenance is simple but important.

- Daily: Clean immediately after each use.

- Periodic: Inspect the viscometer for any cracks, chips, or stubborn residue.

- Troubleshooting:

- Inconsistent flow times? Check for bubbles, particles in the sample, or temperature fluctuations in the bath.

- Flow time too fast or slow? You are likely using the wrong size viscometer for your sample's viscosity.

Storage Recommendations

When not in use, the viscometer should be stored clean and dry. It's best to store it vertically in a dust-free cabinet or a dedicated rack. This prevents dust from settling inside the capillary and protects it from accidental breakage.

What Standards and Regulations Apply to Ubbelohde Viscometers?

You need your measurements to be accepted by customers or regulators. Adhering to recognized standards like ASTM and ISO ensures your data is credible and comparable across different labs.

The use of Ubbelohde viscometers is governed by international standards, primarily ASTM D445 and ISO 3104. These documents detail the exact procedure for measuring kinematic viscosity, ensuring global consistency and data reliability.

For my B2B customers, compliance with standards is not optional. When Jacky's clients in Italy buy lab instruments, they expect them to perform according to these globally recognized methods. Following the standard is how you prove your quality.

ASTM and ISO Standards

The most important standard for this method is ASTM D445, titled "Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids." The corresponding international standard is ISO 3104. These documents provide the definitive rulebook for the procedure. They specify everything from the apparatus dimensions and temperature control requirements to the cleaning procedure and how to calculate the final result. If someone asks if your measurement is "official," they are asking if you followed this standard.

Industry-Specific Regulations and Quality Assurance

Many industries build on these base standards. For example, the pharmaceutical industry might have additional requirements in its pharmacopeia (e.g., USP) that reference the ASTM method but add further stipulations for documentation and validation. In any quality assurance (QA) system, following these standardized methods is a core requirement. It ensures that the viscosity measurement is not just a number, but a traceable, verifiable fact about the product. This is essential for lot release, quality control charts, and resolving any disputes with customers.

How Does the Ubbelohde Compare to Other Viscometers?

You have several types of viscometers in your lab. Knowing when to use the Ubbelohde versus another type, like a rotational viscometer, is key to efficient and accurate testing.

The Ubbelohde is superior for high-precision kinematic viscosity of low-viscosity, Newtonian fluids. Rotational viscometers are more versatile, able to measure non-Newtonian fluids, apparent viscosity, and behavior across different shear rates.

This is a question I love because it gets to the heart of my business. My company, Martests, makes rotational viscometers, so I know their strengths well. But I also respect the specific strengths of capillary viscometers. Choosing the right tool for the job is what makes a good scientist or engineer.

Comparison with Other Viscometers

Let's compare them directly.

| Viscometer Type | Best For | Measures | Key Advantage | Key Disadvantage |

|---|---|---|---|---|

| Ubbelohde | Low-viscosity, Newtonian fluids (e.g., solvents, dilute polymers) | Kinematic Viscosity | High precision, low cost | Manual, only one shear rate, not for non-Newtonian fluids |

| Ostwald/Cannon-Fenske | Similar to Ubbelohde but less precise | Kinematic Viscosity | Simpler design | Results depend on sample volume |

| Rotational (like ours) | Non-Newtonian fluids (e.g., paints, foods, creams) | Apparent Viscosity, Shear Stress | Versatile, measures vs. shear rate, automated | Higher cost, more complex |

Selection Criteria for Different Applications

So, when should you choose an Ubbelohde?

- Choose Ubbelohde if: You need to determine the intrinsic viscosity of a polymer, require a reference standard for kinematic viscosity, or are performing standardized fuel/oil tests on a budget. Your fluid must be transparent and Newtonian.

- Choose a Rotational Viscometer if: Your fluid is non-Newtonian (like paint that thins when brushed), you need to check viscosity at different rotational speeds (shear rates), or you need quick QC results in a production environment.

What Are Some Best Practices and Tips for Using This Instrument?

You want to avoid common mistakes and get the best possible results. Following expert tips and best practices can significantly improve your measurement quality and efficiency.

To ensure accuracy, always use a clean viscometer, allow ample time for temperature stabilization, keep the viscometer perfectly vertical, and use a stopwatch with good resolution. Proper sample handling is also critical.

Over the years, I've seen a few simple mistakes cause a lot of frustration. Getting these small details right is what separates an expert user from a novice. Here are a few tips I always share.

Sample Handling and Error Prevention

- Filter your samples: Even tiny dust particles can partially block the capillary and ruin your measurement.

- Avoid bubbles: Introduce the sample slowly down the side of the filling tube to avoid creating air bubbles.

- Keep it vertical: The viscometer must be perfectly vertical in the bath. Any tilt will change the hydrostatic pressure and affect the flow time. Use a plumb line to check.

- Don't skimp on temperature: Give the sample plenty of time to reach the bath temperature. I recommend at least 20 minutes. For more viscous fluids, wait even longer.

Result Interpretation and Safety

- Check for consistency: Your repeated flow times should be very close to each other (e.g., within 0.2%). If they are not, something is wrong. Don't just average them; find the problem. It could be temperature fluctuation or a dirty viscometer.

- Safety first: You are working with glass and potentially hazardous chemicals. Always wear safety glasses. When cleaning with flammable solvents, ensure there is good ventilation and no ignition sources nearby. Handle the viscometer gently to avoid breakage.

Conclusion

The Ubbelohde viscometer is a powerful tool for precise kinematic viscosity measurement. Its elegant design delivers accuracy and reliability, especially for research, development, and standardized testing of Newtonian fluids.