NTV-S Series Intelligent Touch Viscometer

- Maximum Range Up to 320,000,000 cP

- Accuracy: ±1%

- Repeatability: ±0.2%

Technical Specifications

Viscosity unit conversion: 1Pa.s=1000mPa.s, 1P=100mPa.s, 1mPa.s=1cP, M=1,000,000, FS=Full Scale

* If the measured viscosity is lower than 15cP, ULR Adapter is required.

** To measure the viscosity from the lower limit to this point, R1 spindle is required.

| Item | NTV-S1 | NTV-S2 | NTV-S3LV | NTV-S3RV | NTV-S3HA | NTV-S3HB |

|---|---|---|---|---|---|---|

| Display | 7-inch color touch screen | |||||

| Measurement Range (cP) | 1*-0.6M | 1*-6M | 10-80M | 100-40M | 200-80M | 800-320M |

| Speed (rpm/min) | 1-60 | 0.1-100 | ||||

| Accuracy | ±1% (Newtonian fluid FS) | |||||

| Repeatability | ±0.2% | |||||

| Spindle | L1, L2, L3, L4 | R2, R3, R4, R5, R6, R7 | ||||

| Power Supply | 100V-240V | |||||

Accessories Solutions

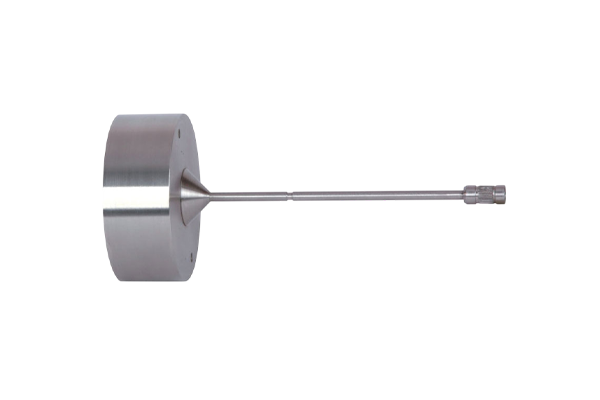

R1 Spindle

PT100 Temperature Probe

- Temperature Range: -40℃-250℃

- Resolution: 0.1℃

- Accuracy: ±0.2℃

Micro Printer

Viscosity Standards

- 450ml per bottle

- 5 cP, 50 cP, 340 cP, 1800 cP, 6190 cP, 9757 cP

Jacketed Glass Beaker

R Spindles Rack

- For Spindles R1, R2, R3, R4, R5, R6, R7

L Spindles Rack

- For Spindles L1, L2, L3, L4

Thermosel System

- Temperature Range: Rt+10℃ to 250℃

- Accuracy: 0.1℃

- Power Supply: 220V or 110V, 300W

NTV-S Series Viscometer Features

Water Baths

- Temperature Range: -20℃ to 100℃

- Accuracy: 0.1℃

Ultra-low Viscosity Adapter

Ideal choice for ultra-low viscosity measurement of samples.

Use our new ultra-low viscosity adapter with our viscometer for precise and repeatable low viscosity measurements. Featuring a cylindrical rotor and tubular sleeve, its design adheres to strict rheological standards for accurate results.

Small-amount Sample Adapter

Suitable for special accessories measuring small-amount sample viscosities.

The small-amount sample adapter has the ability to measure the absolute viscosity under the specified accurate shelf rate. They are composed of a cylindrical sample cylinder and a spindle. The required sample size is small, only 8 to 13 mL.

Effectively Manage Quality Issues

Reasons for Rework

- Failure to Meet Precision Requirements

- Design or Manufacturing Defects

- Software Malfunctions

Reasons for Replacement

- Critical Component Failure

- Persistent Performance Issues

- Equipment Incompatibility