Your viscometer gives you a number, but your product still fails. You can't explain why your paint sags or your cream feels wrong, leading to endless guesswork.

A viscometer tells you how thick a fluid is under one condition. A rheometer explains why it behaves the way it does across many conditions—how it spreads, sags, or holds its shape. It measures behavior, not just viscosity.

I hear this question often. A client, a purchasing manager like Jacky from Italy, will call me. He'll say, "Stefan, my Martests viscometer says the viscosity is 5000 cP. But this batch of paint sags on the wall, and the last batch didn't. What's wrong?" This is a classic problem. The viscometer is telling the truth, but it's not telling the whole truth. The single number it provides is not enough to predict complex behaviors like sagging. Let's explore the difference and see when you need to look beyond a simple viscosity measurement.

What is the real difference between a viscometer and a rheometer?

You think viscosity is the only thing that matters. But your data doesn't match real-world performance, leaving you confused and unable to predict your product's behavior.

A viscometer gives a single-point measurement of flow resistance (viscosity). A rheometer measures a full profile of flow and deformation, including viscosity, elasticity, and yield stress. It provides a much more complete picture.

Think of it this way: a viscometer gives you a snapshot, while a rheometer gives you the whole movie. My company, Martests, builds excellent rotational viscometers that are perfect for many tasks, especially quality control. They answer the question, "How thick is this liquid right now?" But sometimes, you need to answer a more complex question: "How will this liquid behave when I pump it, spread it, or just let it sit?" That is where a rheometer comes in. It's a more advanced tool designed to provide a deeper understanding of a material's properties.

What a Viscometer Measures

A viscometer is designed to do one thing very well: measure a fluid's resistance to flow under a specific, controlled condition. You choose a spindle and a speed, and it gives you a viscosity value. This is extremely useful for quality control. You can quickly check if Batch 101 is the same as Batch 100. It's a simple, fast, and reliable pass/fail test.

What a Rheometer Measures

A rheometer does much more. It can measure how a material responds to stress and strain over a wide range of conditions. This gives you data on properties a viscometer can't see.

| Feature | Viscometer | Rheometer |

|---|---|---|

| Primary Measurement | Viscosity (at one or a few shear rates) | Viscosity, Elasticity, Yield Stress, Creep, Recovery |

| Typical Use | Quality Control (QC) | Research & Development (R&D), Complex Troubleshooting |

| Question Answered | "How thick is it?" | "How does it behave and why?" |

| Analogy | A single photograph | A full-length movie |

How do I know when my viscometer is not enough for the job?

Your QC tests pass, but the final product is inconsistent. Customers complain about texture or stability, and you can't figure out why some batches are different.

You need more than a viscometer when dealing with complex fluids like gels, emulsions, or suspensions. It's also necessary when troubleshooting formulation issues or moving from basic QC checks to in-depth research and development.

This is the exact point where many of my customers realize they need more data. They are making complex products, but using a simple test. For many fluids like water or simple oils (Newtonian fluids), viscosity is constant. A viscometer is perfect for these. But most modern products are not simple. Think about paint, yogurt, adhesives, or cosmetic creams. These are non-Newtonian fluids. Their viscosity changes depending on what you are doing to them. A single viscosity number is misleading because their "thickness" is not a fixed property. It changes when you stir, pour, or spread them.

Complex Materials Demand More Data

When you brush paint onto a wall, you want its viscosity to be low so it spreads easily. But as soon as you stop brushing, you want its viscosity to become very high so it doesn't drip. This change in viscosity cannot be captured by a single measurement. A viscometer might tell you the viscosity in the can is correct, but a rheometer will tell you if it will spread smoothly and resist sagging on the wall. The same applies to an emulsion like a lotion or a suspension like a pharmaceutical syrup.

From Quality Control to Research & Development

There is a clear difference between the needs of a QC lab and an R&D lab.

- QC Lab: The goal is consistency. "Is this batch the same as the last good batch?" A viscometer is often the perfect tool for this. It provides a fast, repeatable number for comparison.

- R&D Lab: The goal is innovation and problem-solving. "How can we make our yogurt feel creamier without adding more fat?" or "Why is this batch of adhesive failing under stress?" To answer these questions, you need to understand the material's underlying structure and behavior. You need a rheometer.

What specific data can a rheometer provide that a viscometer can’t?

Your paint drips, but its viscosity is correct. Your lotion feels greasy, but the QC check passed. You are missing the critical data that explains these real-world problems.

A rheometer measures yield stress (the force to start flow), thixotropy (how a fluid thins under shear and recovers over time), and viscoelasticity (solid-like and liquid-like properties). A viscometer typically cannot measure these.

This is where the investment in a rheometer pays off. It provides specific, actionable data that connects directly to product performance and customer experience. Let's look at three key properties that a viscometer just can't measure.

Yield Stress: The "Ketchup" Problem

Yield stress is the minimum amount of force needed to make a material start to flow. Think about thick ketchup in a glass bottle. It won't come out until you hit the bottle hard enough to overcome its yield stress. In paints, a high yield stress prevents sagging on a wall. In cosmetics, it keeps a thick cream from running out of a jar but allows it to spread easily once you apply force. A viscometer rotating at a constant speed has already overcome the yield stress, so it cannot measure it.

Thixotropy: The "Paint" Solution

Thixotropy describes how a material's viscosity changes with time. Good paint is a perfect example. It thins when you brush it (easy application) and then thickens again on the wall to prevent drips. A rheometer can measure this structural recovery over time. This data helps you formulate a paint that is easy to apply but also gives a smooth, drip-free finish.

Viscoelasticity: The "Gel" Secret

Many materials, like gels and polymers, have both liquid-like (viscous) and solid-like (elastic) properties. A rheometer can measure this using an oscillatory test. It applies a small, gentle back-and-forth motion to the sample. This tells you about the material's internal structure. For a hair gel, this data explains how it holds its shape in the jar (solid-like behavior) but flows easily when you scoop it out (liquid-like behavior). This balance is critical for how a customer perceives the product.

How can I decide if my lab truly needs to invest in a rheometer?

You are considering a rheometer, but it's a big investment. You are worried it might be overkill for your needs, leading to wasted money and added complexity.

Decide by evaluating your goals. If you only do basic QC on simple fluids, a viscometer is enough. If you develop new products, troubleshoot complex issues, or characterize non-Newtonian materials, the investment in a rheometer provides essential insights.

It is a business decision, so you need to weigh the cost against the benefits. I always tell my clients to be practical. You don't need the most advanced tool if a simpler one does the job. Let's break it down to help you decide.

A Simple Checklist for Your Lab

Ask yourself these questions:

- What is my main goal? If you are just doing pass/fail QC checks on the same product every day, a robust viscometer is probably all you need. If you are trying to create new formulations or understand why a product fails, you need more data.

- What materials am I testing? For simple liquids like oils or solvents, a viscometer is perfect. For complex materials like suspensions, emulsions, gels, or polymers, a rheometer is essential.

- What problems am I trying to solve? If customers complain about texture, stability, or application feel even when your viscosity is "correct," that is a clear sign you need a rheometer.

Cost vs. Insight

A rheometer is more expensive than one of my Martests viscometers. There is no question about that. But think about the cost of not having the right data. How much does a single failed batch cost you? How much time and money is wasted on trial-and-error formulation? A rheometer can pay for itself by solving one major production issue or helping you launch one successful new product. It's an investment in efficiency and innovation.

Using Both for a Perfect Workflow

The best setup I see in large companies is using both instruments. The R&D lab uses a rheometer to fully understand a new material and develop the perfect formulation. During this process, they identify one or two key parameters that predict performance. Then, the QC lab uses a simpler, robust viscometer (like the ones we make at Martests) to run that one specific test on every batch. It's a smart, efficient, and cost-effective system.

If I need a rheometer, how do I choose the right one?

You have decided you need a rheometer, but the options are overwhelming. Choosing the wrong one means you might not get the data you need for your specific materials.

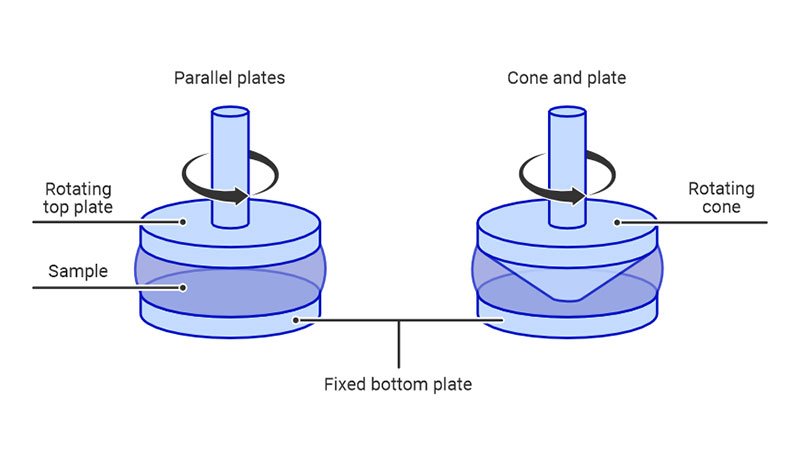

Choose a rheometer based on your sample type and the properties you need to measure. Rotational rheometers are versatile for fluids, while oscillatory tests are key for viscoelasticity. The right geometry (cone-plate, parallel-plate) is also crucial.

Even though my factory focuses on producing the best rotational viscometers, my team and I work within the broader world of material science every day. We understand the principles behind all these instruments. When you decide to buy a rheometer, it’s not just about the hardware. You need to consider the types of tests you will run and the samples you will measure.

Rotational vs. Oscillatory Modes

Most modern rheometers can perform both rotational and oscillatory tests.

- Rotational tests are for measuring viscosity as a function of shear rate, just like a viscometer but over a much wider range. This is great for creating flow curves and measuring yield stress.

- Oscillatory tests are different. They apply a very small, back-and-forth wiggle to the sample. This lets you measure the solid-like and liquid-like properties (viscoelasticity) without destroying the material's internal structure. This is essential for studying gels, polymers, and emulsions at rest.

Why an Experienced Partner Matters

Whether you are buying a viscometer or a rheometer, you are buying more than just a machine. You are buying a tool that produces data to help you make decisions. Working with an experienced manufacturer is key. At Martests, we don't just ship boxes from China. We work with our distributors and customers in Europe, the Middle East, and South America to ensure they understand how to get accurate results and what those results mean. This expertise and support is the real value. Choosing a partner who understands your application is just as important as choosing the right instrument.

Conclusion

A viscometer measures flow, but a rheometer explains behavior. Knowing when to use each tool is the key to mastering your material and creating better, more consistent products.