Your viscosity measurements are all over the place. One day the reading is high, the next it is low, but the sample is the same. This inconsistency is frustrating.

Shear rate is the speed at which a fluid is deformed. It is the velocity difference between layers of a fluid divided by the distance between those layers. It is essential for understanding how fluids really behave.

I often talk to customers, like Jacky from Italy, who are experts in their field but get confused by this one term. They will say, "Stefan, I measured my adhesive's viscosity, but the result doesn't match what I see in production." The problem is almost always that they are not considering the shear rate. Understanding this single concept can transform your quality control from a guessing game into a science. Let's break it down into simple ideas.

What exactly does “shear rate” mean in fluid mechanics?

You hear the term "shear rate" but don't really know what it means. This makes your viscosity data confusing and unreliable, which can lead to bad production decisions.

Shear rate measures how fast a fluid is sheared or deformed. Think of it as layers of fluid sliding past each other. Its unit is reciprocal seconds, or s⁻¹.

Let's make this concept very simple. Imagine you have a deck of cards on a table. If you place your hand on top and push it sideways, the cards slide over one another. This sliding motion is "shear." The speed at which you push your hand, divided by the height of the deck, gives you the shear rate. Fluid mechanics works the same way, but with imaginary layers of liquid instead of cards.

A Simple Definition

Shear rate is the rate at which a fluid's layers move past each other. A high shear rate means the layers are moving very fast relative to each other. A low shear rate means they are moving slowly.

Units and Example

The standard unit for shear rate is reciprocal seconds (s⁻¹). This unit just means "per second."

- Low Shear: A paint slowly leveling on a wall is under a very low shear rate (maybe 0.1 s⁻¹).

- High Shear: Brushing that same paint onto the wall creates a high shear rate (maybe 10,000 s⁻¹).

Understanding this difference is the first step to controlling your fluid's behavior.

Why is shear rate important for viscosity and flow behaviour?

You treat all fluids the same. This leads to production problems because materials like paint or yogurt change their thickness under different conditions, and you don't know why.

Shear rate is crucial because many fluids are non-Newtonian, meaning their viscosity changes with shear rate. This affects everything from pumping a liquid through a pipe to spreading it on a surface.

The relationship between shear rate, the force you apply (shear stress), and the resulting thickness (viscosity) is the most important concept in viscosity measurement. The basic formula is:

Viscosity = Shear Stress / Shear Rate

This means viscosity is not always a single number. It is a property that can change.

Newtonian vs. Non-Newtonian Fluids

This is where the importance of shear rate becomes clear.

| Fluid Type | Behavior with Shear Rate | Examples |

|---|---|---|

| Newtonian | Viscosity is constant. It does not change with shear rate. | Water, oil, honey (at a constant temperature). |

| Non-Newtonian | Viscosity changes when the shear rate changes. | Paint, ketchup, blood, polymer solutions. |

Most industrial fluids are non-Newtonian. Ketchup gets thinner when you shake it (high shear rate) so it can flow out of the bottle. This is called shear-thinning behavior. Understanding this allows you to design better processes for mixing, pumping, and applying your products.

How is shear rate calculated in practical situations, including using a viscometer?

You have a viscometer but don't know how its numbers relate to shear rate. Your measurements are not comparable to data from other labs, causing confusion and quality disputes.

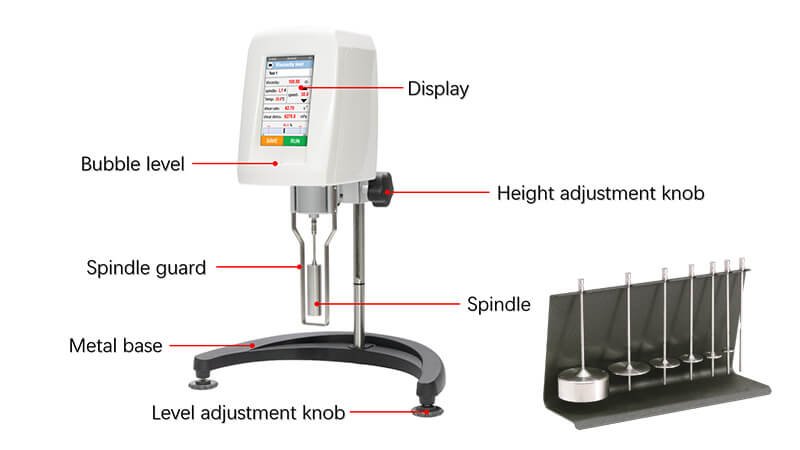

In a lab, shear rate is determined by the instrument's geometry and speed. For a rotational viscometer, it is calculated from the spindle's rotational speed, its size, and the sample container.

You cannot measure shear rate with a ruler. You need a specialized instrument that controls the conditions of the measurement.

Simple Geometries

The easiest way to understand the calculation is with two parallel plates. One plate is still, and the other moves. The shear rate (γ̇) is simply the velocity (v) of the moving plate divided by the height (h) of the gap between them.

γ̇ = v / h

If you move the plate faster, the shear rate increases. If the gap is smaller, the shear rate also increases.

Using a Rotational Viscometer

In my business, we sell rotational viscometers. These instruments are designed to create a well-defined shear environment. The shear rate is no longer a simple calculation, but the principle is the same. The instrument's software uses the rotational speed (RPM) and the specific geometry (like a cone and plate or cup and bob spindle) to calculate the precise shear rate being applied to the sample. This is why choosing the right spindle and setting the correct speed is so important for getting accurate, repeatable data. This is a key function we build into every Martests viscometer.

What are the different regimes of shear-rate behaviour in fluids and materials?

Your material behaves perfectly in the lab but fails in production. The different shear rates between testing and your real-world application are the likely cause of this mismatch.

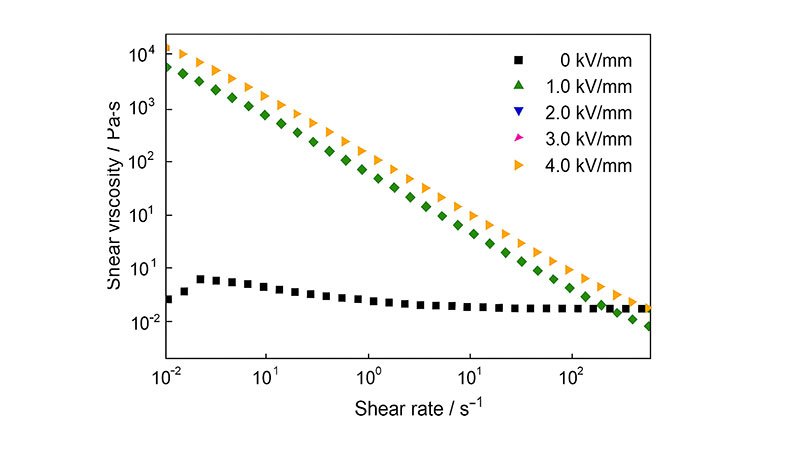

Fluids can be shear-thinning (viscosity decreases with shear) or shear-thickening (viscosity increases). Understanding this behavior at both low and high shear rates is vital for quality control.

Most complex fluids do not have one single viscosity value. Their behavior changes depending on how fast you shear them. Recognizing this behavior is critical for success.

Shear-Thinning vs. Shear-Thickening

These are the two most common non-Newtonian behaviors.

| Behavior | Description | Real-World Example | Why It's Useful |

|---|---|---|---|

| Shear-Thinning | Viscosity decreases as shear rate increases. The fluid gets "thinner" when you stir or shake it. | Paint, ketchup, shampoo. | Easy to apply (spray, brush, pour) at high shear, but thick enough to stay in place at low shear (on a wall or in your hair). |

| Shear-Thickening | Viscosity increases as shear rate increases. The fluid gets "thicker" with impact or rapid motion. | Cornstarch and water mixture, some industrial fluids. | Can be used in applications like liquid body armor, where the material needs to become rigid upon impact. |

Knowing which category your product falls into is essential. You need to test it at shear rates that match its final application, from sitting on a shelf (low shear) to being used by a customer (high shear).

How does shear rate relate to using a rotational viscometer in your lab?

You report a viscosity value without context. This makes your data meaningless and impossible to reproduce, causing quality control disputes with your suppliers or customers.

When reporting viscosity for a non-Newtonian fluid, you must also state the shear rate. A professional rotational viscometer, like ours from Martests, allows you to control this for consistent results.

This is the final and most important point for any lab manager or purchasing manager. A viscosity number by itself is often useless.

Why Specifying Shear Rate Matters

Saying "the viscosity of my paint is 1000 cP" is like saying "the car was driving at 50." 50 what? Miles per hour? Kilometers per hour? For a non-Newtonian fluid, a viscosity value needs context. The correct way to report it is: "The viscosity is 1000 cP at a shear rate of 10 s⁻¹." This makes the data precise, repeatable, and comparable with data from any other lab in the world. As a manufacturer of these instruments, we design our Martests viscometers to give you this exact control. We offer customizable options so you can set the specific shear rates you need for your quality control.

Practical Tips for Users

- Match the Application: Test your samples at shear rates that mimic real-world conditions (pumping, spraying, leveling).

- Create a Flow Curve: Measure viscosity at a range of different shear rates to fully understand your material's behavior.

- Be Consistent: Always use the same spindle, speed, and temperature for your QC tests to ensure your results are comparable over time.

Conclusion

Shear rate is not just a technical term. It is the key to understanding viscosity, controlling your product quality, and solving real-world processing and performance problems effectively.