Your material is solid at room temperature, but flows when hot. Standard instruments can't measure it, leading to inconsistent product quality and costly production mistakes. You need a better way.

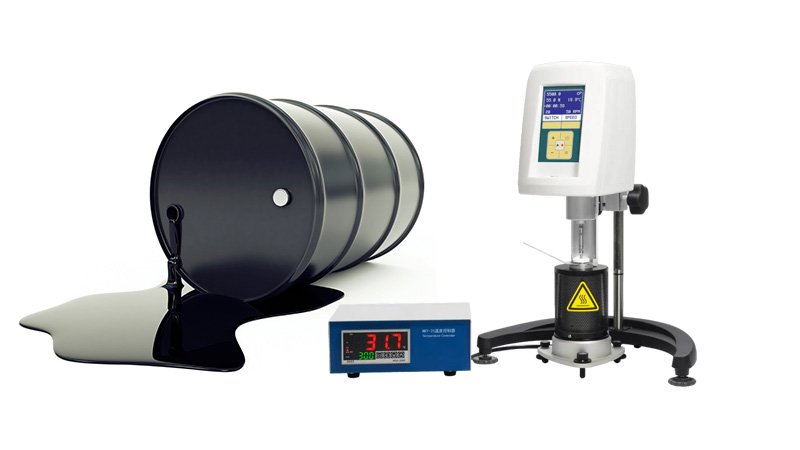

A high temperature viscometer is a specialized instrument designed to measure the viscosity of materials like waxes, polymers, and hot-melt adhesives at elevated temperatures. It uses a controlled heating system, like a Thermosel, to ensure accurate and repeatable results for quality control.

Many of my customers, including experienced buyers like Jacky from Italy, handle materials that change dramatically with heat. They know that a simple viscosity number at room temperature is useless for a hot melt adhesive or asphalt. The real performance happens at high temperatures, during application. That is why understanding this specialized equipment is so important. It is the key to controlling quality for some of the most common industrial materials. Let's look at how it works and why it matters.

What is a High Temperature Viscometer and How Does It Work?

You try using a standard viscometer for hot samples, but the temperature is unstable. This makes your viscosity readings unreliable, and you cannot trust your own quality control data.

A high temperature viscometer uses an integrated heating chamber, often called a Thermosel System, to maintain a precise, uniform temperature around the sample. This allows for accurate measurement of fluids that are solid or semi-solid at room temperature.

The main idea is simple: to get a good measurement, the sample's temperature must be stable. This instrument is built specifically to achieve that stability at very high temperatures.

Definition and Purpose

A high temperature viscometer is not just a standard viscometer with a heater nearby. It is a complete system designed to control the sample's environment. Its main purpose is to test materials that are only liquid at high temperatures. Think of hot melt glues, asphalt for roads, or polymers used in molding. For these products, viscosity at the application temperature determines their performance.

The Thermosel System

The core of the instrument is the Thermosel. It is a small, insulated oven that contains the sample cup and the viscometer spindle.

- An electric heater surrounds the sample chamber.

- A precise temperature sensor measures the sample's temperature.

- A controller uses this information to keep the heat perfectly steady.

This system ensures the entire sample, from top to bottom, is at the exact same temperature during the test.

Key Differences

| Feature | Standard Viscometer | High Temperature Viscometer |

|---|---|---|

| Temperature Control | None, or uses a water bath | Integrated Thermosel (up to 300°C+) |

| Sample Holder | Standard beakers | Small, metal, disposable or reusable chambers |

| Spindles | Reusable stainless steel | Often disposable to avoid difficult cleaning |

| Safety | Basic | Insulated chamber to protect the operator |

Why is Accurate High-Temperature Viscosity Measurement Important?

You assume your hot material behaves the same in every batch. This leads to unexpected failures during application, causing product rejections and wasting both time and money.

Accurate high-temperature viscosity measurement is critical for quality control. It predicts how materials like asphalt, polymers, and adhesives will behave during processing and application, preventing costly failures and ensuring consistent product performance.

This isn't just about getting a number; it's about predicting success or failure in the real world. A small change in viscosity at 200°C can mean the difference between a strong bond and a weak one.

The Role of Viscosity in Quality Control

For materials applied hot, viscosity is the most important quality parameter. It tells you if a hot melt adhesive will flow properly through a nozzle, or if asphalt will be workable for a paving crew. By checking the viscosity of every batch, you ensure that the product will perform as expected for your customer.

How Temperature Affects Fluid Behavior

Heat gives molecules more energy, allowing them to move more freely. This almost always causes viscosity to drop.

- Hot Melt Adhesives: Must have low enough viscosity at application temperature to spray easily, but become thick very quickly as they cool to create a strong bond.

- Polymers: The viscosity of a polymer melt determines how easily it fills an injection mold. Too high, and the part has defects. Too low, and it may not have the right strength.

- Wax: Needs the right viscosity to create a thin, even coating on paper or fruit.

Inaccurate readings can hide problems until it is too late, leading to weak adhesive bonds, poor-quality molded parts, or roads that fail prematurely.

How Does the Thermosel System Ensure Stable and Reliable Results?

Your temperature fluctuates during high-heat tests. This makes your results inconsistent, and you cannot tell if a problem is from the material batch or your testing method.

The Thermosel System ensures stability by using a small, insulated sample chamber for precise temperature control. This design minimizes temperature gradients, making every measurement highly reproducible and reliable for strict quality control.

Reliability is the most important feature for any quality control instrument. When I talk with factory managers, their biggest fear is unreliable data. The Thermosel is designed to eliminate that fear.

The Principle of Precise Temperature Control

The system works like a thermostat in your home, but much more precise. The controller constantly compares the actual sample temperature to your setpoint. If it drops even slightly, it sends more power to the heater. If it gets too hot, it cuts the power. This continuous adjustment keeps the temperature incredibly stable, often within ±0.1°C of your target. This stability is the foundation for getting a reliable viscosity number.

Advantages of a Small, Insulated Sample

Using a small sample chamber has two big benefits. First, a small amount of material heats up very quickly and evenly. There are no cold spots. Second, the heavy insulation around the chamber prevents heat from escaping. This means the system does not have to work hard to maintain the temperature, which further improves stability. It also makes the instrument safer for the person operating it.

Reproducibility and Consistency

All these design features—precise control, a small sample size, and excellent insulation—work together for one goal: reproducibility. This means if you test the same sample today and again next week, you will get the same result. This consistency is essential for good quality control. It allows you to confidently compare different batches of raw materials or finished products.

Where Can You Apply the High Temperature Viscometer?

You work with hot melts, asphalt, or polymers. You know you need better quality control but are not sure if this is the right instrument for your specific application.

High temperature viscometers are essential for quality control and R&D in many industries. They are used for testing hot melt adhesives, asphalt, polymers, resins, waxes, and other materials that are processed at high temperatures.

This instrument is a problem-solver for any industry that heats a material to make it flow. As a manufacturer at Martests, we build these viscometers to be versatile, with customizable options for different materials. Here are the most common applications I see with my customers.

| Application | Material Examples | Why High-Temp Viscosity is Critical |

|---|---|---|

| Adhesive Manufacturing | Hot melt adhesives (EVA, polyurethane) | Ensures the adhesive flows correctly from the application nozzle and sets properly upon cooling. Viscosity directly relates to bonding strength and open time. |

| Asphalt & Bitumen | Paving grade asphalt, roofing tar | Determines the correct mixing and paving temperatures. The wrong viscosity can lead to poor road compaction and premature failure. |

| Polymer Processing | PET, PVC, polymer melts | Predicts how the material will behave during injection molding or extrusion. It is essential for preventing defects and ensuring final part strength. |

| Wax Production | Paraffin wax, beeswax, coatings | Controls the quality of wax coatings on paper and cardboard. It also ensures candles burn evenly and cosmetics have the right texture. |

| Research & Development | New material formulations | Allows scientists to study how new polymers or blends behave at different temperatures, helping them create better products with specific properties. |

Conclusion

A high temperature viscometer with a Thermosel system is not a luxury. It is an essential tool for quality control in industries working with hot materials like asphalt and adhesives.