You bought a new viscometer, but your results are still wrong. This wastes money and puts product quality at risk. Avoiding common selection mistakes ensures accurate, reliable data.

The top mistakes include ignoring viscosity range, overlooking temperature control, disregarding sample type, forgetting software needs, and focusing only on price. Avoiding these ensures you select a viscometer that provides accurate, repeatable results for your specific application, saving time and money.

I've seen many clients, like Jacky from Italy, struggle after a poor purchasing decision. They focus on one feature and forget the bigger picture. A viscometer is a big investment. Making the right choice from the start is critical. Let's break down the five most common mistakes I see so you can avoid them.

Are you ignoring the required viscosity and shear rate range?

Your viscometer can't measure your thickest samples. This forces you to use another instrument, wasting time and creating inconsistent data. You need a device that covers your full range.

You must choose a viscometer whose measurement range covers the full viscosity and shear rate spectrum of your samples. A mismatch leads to inaccurate readings or the inability to test certain materials, making the instrument useless for your critical quality control processes.

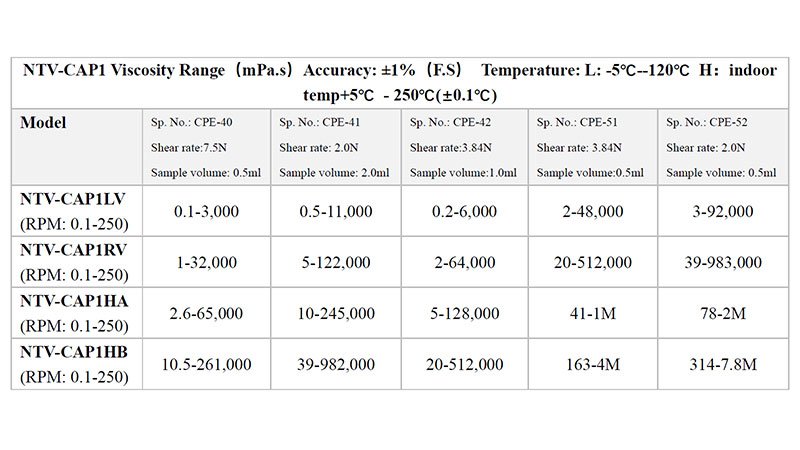

This is the most critical mistake I see. A cone and plate viscometer is not a one-size-fits-all tool. The specific cone geometry and the instrument's speed capabilities define its working range. I remember a customer who bought a viscometer for testing cosmetic lotions. Later, they tried to test a much thicker cream and found the instrument gave an "over-torque" error. It simply wasn't built for that high viscosity. They failed to match the viscometer to their complete product line. Before you buy, you must know the minimum and maximum viscosity you need to measure. You also need to know the shear rates your product experiences in its real-world application. Based on that, the supplier can recommend the right combination of instrument model and cone spindle.

Matching Cones to Viscosity

| Cone Type | Typical Viscosity Range | Example Application |

|---|---|---|

| Low Viscosity Cone (e.g., CPE-42) | 1 - 2,000 cP | Solvents, Inks, Beverages |

| Mid Viscosity Cone (e.g., CPE-51) | 100 - 20,000 cP | Motor Oils, Paints, Lotions |

| High Viscosity Cone (e.g., CPE-52) | 500 - 80,000 cP+ | Adhesives, Gear Greases, Creams |

Do you underestimate the importance of temperature control?

Your viscosity readings are inconsistent batch-to-batch. The problem might be temperature fluctuations you can't see. Precise temperature control is not optional; it's essential for accuracy.

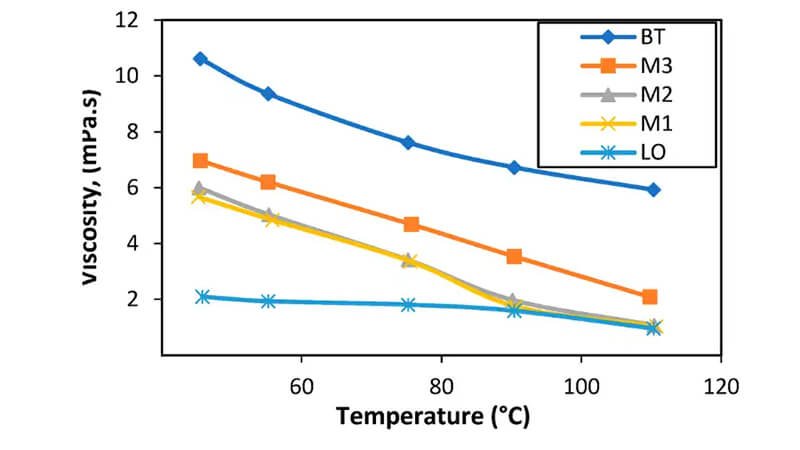

Viscosity is highly sensitive to temperature. Failing to choose a viscometer with precise, integrated temperature control is a major error. Even a one-degree change can significantly alter results, leading to false passes or failures in your quality control checks.

Think about motor oil. The "5W-30" rating on the bottle is all about its viscosity at different temperatures. It's the same for nearly every fluid. As temperature increases, viscosity almost always decreases. If your lab temperature changes by a few degrees during the day, your viscosity readings will change too, even if the sample is identical. This creates chaos for quality control. A professional cone and plate viscometer must have an integrated system to control the plate's temperature. Peltier-based systems are excellent because they can heat and cool rapidly with high precision, often holding the temperature to within ±0.1°C. For my clients in Southeast Asia, where ambient lab temperatures can be high and variable, this feature is a lifesaver. It guarantees that a test done in the morning gives the same result as a test done in the afternoon. It removes temperature as a variable, so you can trust your data.

Have you considered your specific sample type and volume?

You're wasting expensive samples with every test. Your instrument requires a large volume, and it's costing you a fortune. Choosing a viscometer suited for small volumes is key.

Cone and plate viscometers are ideal for small, often expensive, samples. Ignoring this advantage or your sample's characteristics, like volatility, is a mistake. You must select a model that fits the volume you can spare and protects the sample's integrity during testing.

One of the best features of a cone and plate viscometer is its tiny sample requirement, usually between 0.5 mL and 2.0 mL. This is a huge advantage in research and development, where new chemical formulations are created in very small, expensive batches. If your instrument needs 10 mL for a test, your R&D costs go up fast. But volume is not the only factor. You have to consider the nature of the sample itself. For instance, if you are testing a solvent-based ink, it will evaporate quickly. This evaporation changes the concentration and therefore the viscosity. For these volatile samples, you need a model with a solvent trap or cover to minimize evaporation during the test. Also, what if your sample contains particles, like in a pharmaceutical suspension? The small gap in a cone and plate system might crush or grind these particles, giving you bad data. I always ask my customers, "What exactly are you measuring?" before I recommend a model. It ensures they get the right tool for their specific sample.

Are you forgetting about software and data management?

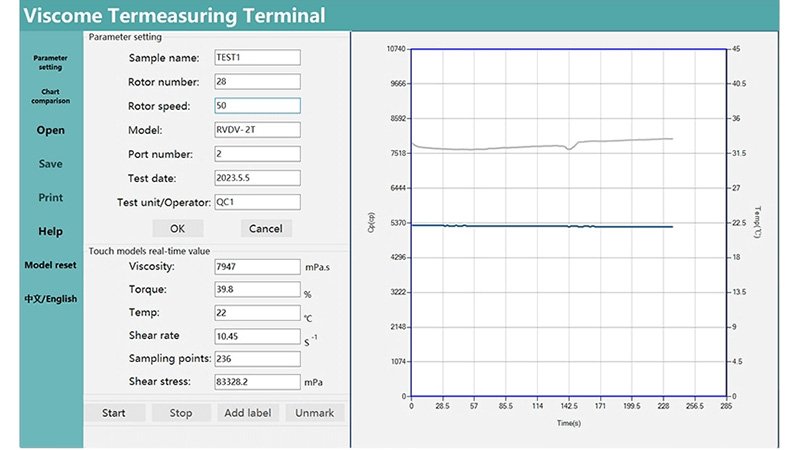

You spend hours manually typing data into spreadsheets. This is slow and prone to errors. Modern viscometer software can automate this, but you didn't think to ask for it.

In today's digital world, ignoring a viscometer's software capabilities is a critical error. Good software automates data collection, analysis, and reporting. This saves time, reduces human error, and helps with quality audits and regulatory compliance.

A modern viscometer without good software is like a powerful car with no steering wheel. The instrument can generate precise data, but you have no efficient way to control it, capture it, or analyze it. When talking to clients, I emphasize that software should be a key part of their decision. Good software allows you to create multi-step test profiles, automatically control speed and temperature, and see the results graphed in real-time. It should let you easily export data to your lab's information system. For my customers in regulated industries like pharmaceuticals or medical devices, features like FDA 21 CFR Part 11 compliance are non-negotiable. This means secure user logins, un-editable results, and a complete audit trail that shows who ran the test and when. My distributor Jacky confirms that his customers won't even consider an instrument without these data integrity features. It's about security, traceability, and efficiency.

Do you focus only on the initial purchase price?

You bought the cheapest viscometer to save money. Now, it needs constant, expensive repairs and gives unreliable results. The low initial price has led to much higher long-term costs.

Choosing a viscometer based on the lowest price alone is a frequent and costly mistake. You must consider the total cost of ownership. This includes build quality, warranty, availability of service and calibration, and the cost of potential downtime.

As a manufacturer, I understand the need to control costs. But a viscometer is a long-term investment, not a disposable item. Focusing only on the sticker price is a classic mistake that often costs more in the end. I encourage buyers like Jacky to look at the Total Cost of Ownership. First, consider the build quality. Is the instrument made with a solid metal casing or flimsy plastic? A robust machine will withstand years of use in a busy lab. Second, what about service and support? If the instrument has a problem, how quickly can you get technical help or spare parts? Downtime in a QC lab can shut down a whole production line. Third, think about calibration. How stable is the instrument? Does it require frequent and expensive service calls? A high-quality viscometer pays for itself through reliability, accuracy, and peace of mind. A slightly higher initial investment often results in a much lower total cost over the instrument's 10-year lifespan.

Conclusion

Choosing the right cone and plate viscometer is about matching the tool to your specific job. Avoid these five mistakes to ensure your investment delivers accurate, reliable results for years.