Your viscometer gives strange readings, disrupting production. This might be due to poor maintenance, not a faulty device. Follow simple steps to ensure accuracy and save money.

To extend your viscometer's life, clean it after every use, handle spindles carefully, and calibrate it annually. Also, inspect the pivot assembly and store it properly. This routine maintenance prevents costly damage and ensures accurate, reliable measurements for years.

I’ve seen many distributors, like my friend Jacky in Italy, prematurely replace perfectly good instruments. They think the viscometer is broken, but it just needs proper care. A viscometer is a precision instrument, and from my years of experience, the biggest oversight is neglecting routine maintenance. Treating it with care is the secret to a long service life and reliable data. This avoids costly replacements and maximizes your investment. Let’s go through the essential steps to protect your instrument.

How crucial is cleaning your viscometer and spindles?

Leftover sample on your spindle is ruining your next test. This contamination gives false high readings. Proper cleaning is a non-negotiable step for getting accurate data every single time.

Cleaning is critical. You must clean the spindles immediately after each use with a non-abrasive solvent and a soft cloth. Dried sample can damage the spindle surface and pivot mechanism, leading to inaccurate results and expensive repairs.

The most common source of error I see is a dirty spindle. When a sample dries on the spindle, it changes its dimensions and surface texture. This completely alters the physics of the measurement, leading to incorrect and inconsistent viscosity readings. A thin layer of dried material can make a low-viscosity sample appear much thicker than it is. It's also important to clean the instrument body, but the spindle is the priority. Never use an abrasive pad or harsh tool to scrape off dried material, as this will scratch the spindle's surface and make the problem even worse. Always clean gently immediately after you finish a measurement. This simple habit is the single most effective thing you can do to ensure reliable results from your viscometer every day.

Spindle Cleaning Guide

| Sample Type | Recommended Solvent | Cleaning Tip |

|---|---|---|

| Oils, Waxes | Mineral spirits, Hexane | Wipe gently with a soaked, lint-free cloth. |

| Aqueous Solutions | Deionized Water, Isopropyl Alcohol | Rinse thoroughly and dry completely before storing. |

| Paints, Inks | Manufacturer-recommended solvent | Avoid strong solvents that could damage the spindle material. |

Are you handling your spindles the right way?

You just dropped a spindle, and now your readings are off. A tiny, invisible bend can ruin its accuracy. Proper handling is the key to protecting these precision-engineered components.

Handle spindles like delicate instruments. Never drop or bend them. Always attach and detach them by lifting the coupling, not by forcing them. Store them in their protective case. A damaged spindle cannot be repaired and must be replaced.

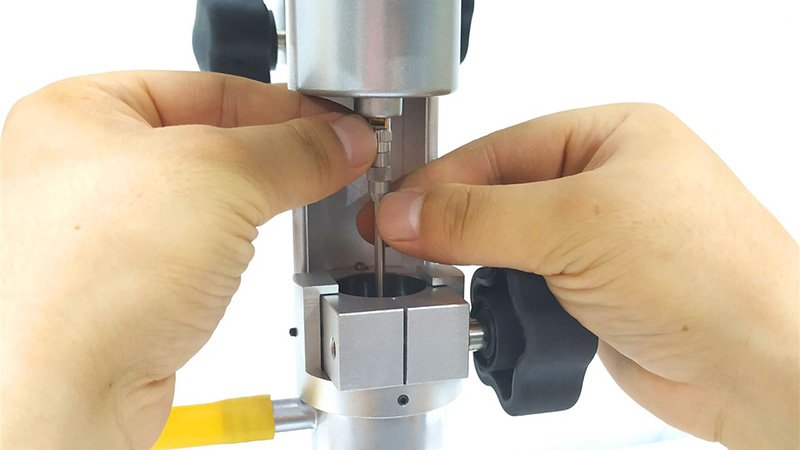

Each spindle is a piece of precision engineering. Its specific shape and dimensions are used in the viscometer's calculations to determine the correct viscosity value. If a spindle is dropped, bent, or even dented, its geometry changes. This change means the calculations are no longer valid, and the viscometer will produce incorrect data. I remember a customer who complained his instrument was reading low. When we investigated, we found his technicians were using small pliers to tighten the spindles, leaving marks on the shaft. This small damage was enough to throw off the results. You must always attach the spindle by gently lifting the coupling screw on the viscometer, screwing the spindle on until it is finger-tight, and then gently releasing the coupling. Never force it, and never apply sideways pressure.

Do's and Don'ts of Spindle Handling

| Do | Don't |

|---|---|

| Lift the coupling before attaching/detaching. | Force the spindle on or off. |

| Store spindles in their dedicated case. | Leave spindles loose on a workbench. |

| Inspect for bends or dents before use. | Use a spindle that has been dropped. |

Why is annual calibration non-negotiable?

You trust your viscometer's data, but it's slowly drifting out of spec. This gradual error can cause major quality control failures. Annual calibration is your only real safeguard.

Annual calibration is essential to verify your viscometer's accuracy against certified standards. This process corrects for electronic and mechanical drift, ensuring your data is reliable and traceable, which is critical for quality audits and ISO compliance.

This is the point I stress most with my customers. A viscometer can seem like it's working perfectly, but over time, all instruments experience "drift." This is a slow, gradual deviation caused by normal wear on mechanical parts and the aging of electronic components. It might only be a 1-2% change per year, but after a few years, your instrument could be significantly out of tolerance. This means you might be passing bad products or failing good ones. Annual calibration by a qualified technician is the only way to detect and correct this drift. They use certified viscosity standard fluids to check the instrument's performance across its range and make necessary adjustments. This service provides a certificate that is often required for quality systems like ISO 9001. It is a small investment to guarantee the integrity of your data.

Simple Calibration Verification Check

| Action | Expected Result | What It Means |

|---|---|---|

| Test a known viscosity standard fluid. | Reading is within the specified tolerance (e.g., ±2%). | Your instrument is likely accurate. |

| Test the same fluid at different speeds. | Calculated viscosity should remain the same. | The instrument is functioning correctly. |

| Reading is outside tolerance. | The instrument's accuracy has drifted. | It's time for professional service and calibration. |

Should you inspect the pivot point and jewel bearing?

Your viscometer's reading is jumpy and unstable. This is often a sign of a damaged pivot point. Ignoring this can lead to complete and expensive instrument failure.

Yes, a visual inspection is helpful, but be gentle. The pivot point and jewel bearing are the heart of a viscometer. A bent pivot or cracked jewel causes friction and erratic readings. Careful spindle handling is the best prevention.

Inside the viscometer, the spindle assembly hangs from a very sharp pivot point that rests inside a cup-shaped jewel bearing. This design allows the spindle to rotate with almost zero friction, which is essential for measuring the tiny rotational drag from a fluid. It is also the most delicate part of the instrument. Pushing a spindle upwards when attaching it, or a sharp knock to the instrument, can bend the pivot or crack the jewel. When this happens, friction increases dramatically. You will see the viscosity reading jump around, or it may seem "sticky" and not return to zero. While you can't repair this yourself, a visual check can help diagnose the problem. Look for a bent pivot needle or any visible damage. The best "maintenance" here is prevention: always handle the instrument gently and attach spindles correctly.

Diagnosing Pivot Point Issues

| Symptom | Possible Cause | Action Required |

|---|---|---|

| Readings are erratic or jumpy. | Bent pivot or cracked jewel bearing. | Stop use and send for professional service. |

| Reading does not return to zero. | Increased friction at the pivot point. | Send for professional service. |

| Grinding or scraping noise. | Severe damage to pivot/bearing assembly. | Immediately power down and schedule service. |

How does proper storage protect your viscometer?

Your viscometer is left on the bench, exposed to dust and bumps. This careless storage can damage its sensitive internal parts. A simple storage routine protects your valuable investment.

Proper storage is crucial. Always return the viscometer to its case with the spindle guard on. This protects the delicate pivot assembly from accidental shocks, dust, and corrosive fumes, which degrade performance and shorten its lifespan.

A viscometer should not be a permanent fixture on your lab bench. When not in use, it needs to be protected. The most important reason is to shield the delicate pivot and jewel bearing from accidental knocks. The shipping case is designed for this. Furthermore, laboratory environments can be harsh. Dust and airborne particles can get into the motor and electronics, causing wear and potential failure. Corrosive fumes from chemicals used elsewhere in the lab can settle on internal components and cause damage over time. One critical component that is often lost is the small plastic spindle guard or shipping cap. This piece is designed to protect the coupling and pivot assembly from upward shocks. Always put this cap back on before placing the viscometer in its case. This simple step can prevent the most common and costly type of damage.

Storage Environment Risks

| Environmental Hazard | Risk to Viscometer | Protective Action |

|---|---|---|

| Physical Shocks/Bumps | Damage to pivot point and bearing. | Use the original case and spindle guard. |

| Dust and Debris | Wear on motor and internal mechanics. | Store in a closed case or under a dust cover. |

| Corrosive Fumes | Damage to electronics and metal parts. | Store in a clean, dry area away from chemicals. |

When is it time to call for professional service?

You've tried everything, but your viscometer is still unreliable. Continuing to use it risks bad batches and lost profits. Knowing when to get expert help is a critical skill.

Call for professional service annually for calibration, or immediately if you notice erratic readings, grinding noises, or physical damage. If the instrument fails a calibration check with standard fluids, it needs professional adjustment and repair.

While daily maintenance is your responsibility, some things must be left to the experts. Attempting to open the viscometer housing and repair it yourself will almost certainly cause more damage and will void your warranty. You should call a qualified service technician for the recommended annual calibration. You must also call them immediately if you encounter problems that basic cleaning and handling checks don't solve. A professional service is much more than just a quick check. A technician will perform a full diagnostic, inspect the motor, drive system, and electronics, and clean and lubricate internal parts. They have the specialized tools and certified standards to accurately adjust the instrument's torque spring and electronics, bringing it back into specification. Think of it like servicing your car; it is preventative maintenance that ensures reliable performance and catches small problems before they become big, expensive ones.

Service Checklist: When to Call an Expert

- The viscometer was dropped or sustained a hard impact.

- Readings are unstable even with a clean, undamaged spindle.

- The instrument makes grinding, scraping, or unusual noises.

- The viscometer fails a verification check with a new, certified viscosity standard fluid.

- It has been more than one year since the last professional calibration.

Conclusion

Consistent cleaning, careful handling, and annual calibration are key. These simple habits protect your viscometer, ensure accurate data, and extend the life of your valuable instrument.