Choosing between a cone and plate viscometer and a rotational viscometer can be overwhelming. Making the wrong choice could lead to inaccurate measurements and wasted resources. I've helped hundreds of labs make this critical decision.

The best choice depends on your specific application. Cone and plate viscometers excel at measuring small sample volumes and high-shear applications, while rotational viscometers offer more versatility across viscosity ranges and are better suited for routine quality control testing.

After testing both types extensively in my lab, I've identified the key factors that should guide your decision. Let me share what I've learned to help you make the right choice for your needs.

What's the Fundamental Difference Between These Two Viscometer Types?

Many lab managers struggle to understand the core differences between these instruments. Without this knowledge, you risk investing in equipment that won't meet your testing requirements.

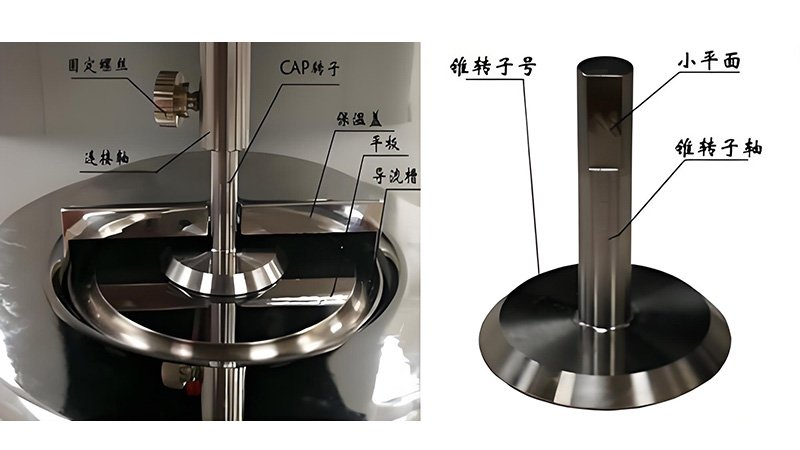

Cone and plate viscometers use a cone-shaped measuring system rotating against a flat plate, while rotational viscometers employ cylindrical spindles rotating in a container of fluid. This basic design difference affects their capabilities and applications.

The fundamental distinction lies in their measuring geometries and principles of operation. Cone and plate systems create a uniform shear rate across the sample, making them ideal for research applications requiring precise rheological characterization. The cone angle (typically 0.5° to 4°) and gap setting are crucial for measurement accuracy.

In contrast, rotational viscometers utilize various spindle geometries, from cylinders to discs, creating different shear conditions throughout the sample. This versatility allows testing of diverse materials but may not provide the same level of precision for complex rheological behavior.

Key Design Features Comparison:

| Feature | Cone and Plate Viscometer | Rotational Viscometer |

|---|---|---|

| Sample Volume | 0.5-2mL | 300-500mL |

| Shear Rate Distribution | Uniform | Variable |

| Temperature Control | Excellent | Good |

| Cleaning Effort | Higher | Lower |

How Do Sample Volume Requirements Impact Your Choice?

I've seen many customers overlook sample volume considerations, leading to workflow inefficiencies and wasted materials. This oversight can significantly impact your testing program's success.

Cone and plate viscometers typically require only 0.5-2mL of sample, while rotational viscometers need 300-500mL depending on the spindle size. This difference is crucial for precious or limited samples.

When working with expensive materials or limited quantities, the small sample volume requirement of cone and plate systems becomes a major advantage. I've helped pharmaceutical companies save thousands in material costs by switching to cone and plate for development work.

For routine quality control testing where sample availability isn't an issue, rotational viscometers offer more practical benefits. Their larger sample volumes can provide more representative results for heterogeneous materials and are less affected by evaporation during long-term testing.

What Role Does Shear Rate Range Play in Selection?

Without understanding shear rate requirements, you might end up with a viscometer that can't properly characterize your materials. This is especially critical in product development and quality control.

Cone and plate viscometers typically achieve higher shear rates (up to 100,000 s⁻¹) compared to rotational viscometers (up to 1,000 s⁻¹). This makes them superior for applications requiring high shear rate testing.

From my experience testing various materials, high shear rates are particularly important in coating applications, polymer processing, and personal care products. The uniform shear field in cone and plate systems provides more reliable data for shear-sensitive materials.

I often recommend rotational viscometers for lower shear applications like food products, paints, and oils. Their robust design and easier cleaning make them more practical for routine testing, though they may not capture complex rheological behavior as accurately.

How Does Cost of Ownership Compare Between the Two Types?

Budget constraints often drive equipment choices, but focusing solely on initial purchase price can be misleading. Understanding total ownership costs helps make a more informed decision.

While cone and plate viscometers typically have higher initial costs ($6,000-12,000) compared to rotational viscometers ($300-5,000), factors like maintenance, accessories, and sample waste affect total ownership costs.

Drawing from my experience maintaining both types, cone and plate systems require more careful handling and precise cleaning procedures. Their sophisticated mechanics and tighter tolerances often mean higher maintenance costs and more frequent calibration requirements.

The simpler design of rotational viscometers generally results in lower maintenance costs and longer service intervals. However, you may need multiple spindles for different viscosity ranges, adding to the total investment. Consider these factors when planning your budget:

Cost Consideration Factors:

| Aspect | Cone and Plate | Rotational |

|---|---|---|

| Initial Investment | Higher | Lower |

| Maintenance Cost | Higher | Lower |

| Consumables | Lower | Higher |

| Training Required | More | Less |

What Are the Main Application Areas for Each Type?

The wrong viscometer choice can lead to unreliable data and wasted time. Understanding typical applications helps avoid these pitfalls.

Cone and plate viscometers excel in R&D, particularly for rheological studies of polymers, cosmetics, and pharmaceuticals. Rotational viscometers are ideal for QC testing of paints, oils, foods, and other industrial fluids.

Based on my extensive testing experience, cone and plate systems are essential for applications requiring detailed rheological characterization or working with small sample volumes. Their precise temperature control and uniform shear field make them perfect for research settings.

Rotational viscometers shine in production environments where quick, reliable measurements are needed. Their robust construction and easier operation make them suitable for routine quality control testing. I've successfully implemented them in paint manufacturing, food processing, and lubricant testing facilities.

Conclusion

Choose a cone and plate viscometer for precise rheological measurements and small samples, or select a rotational viscometer for routine quality control and versatility across various materials. Consider your specific needs in sample volume, shear rate requirements, and budget constraints.