Are you confused about whether to test for viscosity or rheology? Many of our customers struggle with this choice when characterizing materials. This confusion can lead to incomplete data and less effective product development.

Rheology is the comprehensive study of how materials flow and deform under applied forces, while viscosity is just one rheological property that measures a fluid's resistance to flow. Rheology examines multiple properties including elasticity, plasticity, and thixotropy, whereas viscosity testing focuses solely on flow resistance.

At Martests, I've worked with clients across various industries for over a decade. I've noticed a growing trend - customers initially asking for simple viscosity measurements often realize they need more comprehensive rheological data to solve their formulation challenges. Understanding the difference between these concepts can save you time and resources while providing more valuable insights about your materials.

What Are the Key Properties Measured in Rheology vs Viscosity?

Have you ever noticed how some materials flow differently under varying conditions? Or why certain products maintain their shape until a specific force is applied? These behaviors can't be explained by viscosity alone.

Viscosity testing measures a single property—resistance to flow—typically expressed in Pascal-seconds (Pa·s) or centipoise (cP). Rheology examines multiple properties including viscoelasticity, yield stress, thixotropy, normal forces, and flow recovery, providing a complete picture of material behavior under different conditions.

I remember visiting a cosmetics manufacturer in Italy who had been using basic viscosity measurements for their lotions. When customers complained about inconsistent product feel during application, they couldn't understand why—their viscosity readings were consistent. After implementing rheological testing with our equipment, they discovered significant differences in shear-thinning behavior between batches.

The key differences in measured properties include:

Viscosity Testing Focuses On:

- Absolute Viscosity - The basic resistance to flow at a single shear rate

- Kinematic Viscosity - Flow resistance considering material density

- Apparent Viscosity - Viscosity measured at specific conditions

Rheology Testing Examines:

- Viscoelasticity - How materials exhibit both solid-like and liquid-like properties

- Yield Stress - The minimum force required to initiate flow

- Thixotropy - Time-dependent viscosity changes

- Normal Forces - Forces perpendicular to the direction of flow

- Creep and Recovery - How materials deform and recover after stress removal

- Storage and Loss Moduli - Energy storage and dissipation during deformation

This broader analysis helps manufacturers understand how their products will perform in real-world conditions. For example, one of our paint industry clients in Spain discovered that two formulations with identical viscosity readings showed completely different application properties when subjected to comprehensive rheological testing. The difference in thixotropic recovery explained why one paint resulted in smoother application and better sag resistance.

How Does Temperature Affect Rheology and Viscosity Measurements?

Are you getting unexpected results when your materials are used at different temperatures? Do your products behave differently in summer versus winter conditions? Temperature effects go beyond simple viscosity changes.

Temperature dramatically affects both viscosity and rheological properties, but in different ways. While viscosity typically decreases with increasing temperature following the Arrhenius equation, rheological properties may show complex temperature-dependent behavior including phase transitions, structural changes, and altered viscoelastic responses.

At our factory, we regularly test materials across temperature ranges for clients. Last year, a food manufacturer from the Middle East approached us with a problem. Their dessert sauce had consistent viscosity at their testing temperature but behaved unpredictably during hot summer shipping. Our rheological testing revealed dramatic changes in elastic properties above 35°C that simple viscosity testing missed.

Temperature affects these measurements in several important ways:

Temperature Effects on Viscosity:

- Inverse Relationship - Most liquids show decreased viscosity at higher temperatures

- Activation Energy - The Arrhenius equation describes how temperature changes affect flow

- Measurement Standardization - Industry standards typically specify exact testing temperatures

Temperature Effects on Rheological Properties:

- Phase Transitions - Materials may undergo structural changes at certain temperatures

- Crossover Points - The balance between elastic and viscous behavior shifts with temperature

- Recovery Kinetics - How quickly materials return to their original state after deformation changes with temperature

- Yield Stress Variations - The force needed to initiate flow often decreases at higher temperatures

- Complex Modulus Changes - Both storage (G') and loss (G") moduli show temperature dependence

Understanding these temperature dependencies is crucial for products used across varying climates. One of our European customers manufactures adhesives used in construction. Through comprehensive rheological testing, they identified critical temperature thresholds where their product's bonding properties changed significantly. This information allowed them to develop specialized formulations for different climate zones, expanding their market reach.

For accurate testing, we recommend evaluating materials across their entire expected usage temperature range rather than at a single point. Our temperature-controlled rotational viscometers allow precise measurements from -20°C to 200°C, providing valuable insights into how materials will perform in real-world conditions.

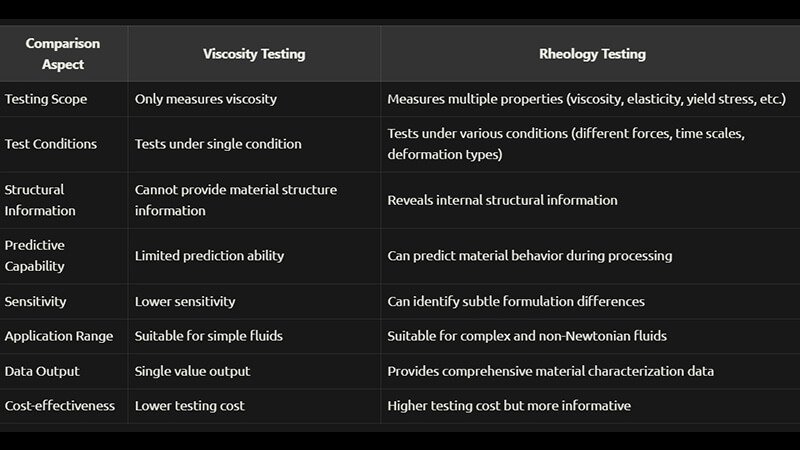

Why Is Rheology Testing More Comprehensive Than Viscosity Testing?

Have you wondered why two materials with similar viscosity can perform so differently in application? Or why some products fail under certain conditions despite meeting viscosity specifications? The answer lies in the limitations of simple viscosity testing.

Rheology testing provides more comprehensive material characterization by examining behavior under various conditions (different forces, time scales, and deformation types). It reveals structural information, predicts processing behavior, and identifies subtle formulation differences that viscosity testing alone would miss.

I recently worked with a pharmaceutical company from Southeast Asia that was developing a new injectable medication. Their initial viscosity testing showed values within specification, but the product wasn't performing consistently during administration. Our rheological assessment uncovered significant differences in elasticity and recovery properties that affected syringe delivery.

Rheology testing offers several advantages over simple viscosity measurements:

Dimensional Analysis

While viscosity testing provides a single data point, rheology offers multi-dimensional analysis including:

- Amplitude Sweeps - How materials respond to increasing deformation

- Frequency Sweeps - Behavior across different time scales

- Temperature Ramps - Property changes during heating/cooling

- Time-Dependent Tests - Structure rebuilding after deformation

Structural Insights

Rheological testing reveals information about internal structure:

- Network Strength - How polymer chains or particles interact

- Dispersion Quality - Distribution of particles in suspensions

- Stability Prediction - Early warning signs of separation or aggregation

- Microstructural Changes - Detection of subtle formulation differences

Processing Behavior

Comprehensive testing predicts how materials will behave during manufacturing:

- Pump Selection - Data for proper equipment sizing

- Mixing Requirements - Force needed for adequate dispersion

- Coating Performance - Spread rates and leveling behavior

- Extrusion Conditions - Pressure requirements and output consistency

One of my clients in the food industry saved substantial production costs after we helped them implement rheological testing. By understanding the complete flow behavior of their chocolate coating, they optimized their production line for perfect coverage while reducing material usage by 12%.

The investment in rheological testing typically pays off through improved product consistency, reduced manufacturing problems, and enhanced end-user satisfaction. While basic viscosity testing remains valuable for quality control, comprehensive rheology provides the insights needed for product development and troubleshooting.

Why Are Both Rheology and Viscosity Important for Quality Control?

Have you struggled with product inconsistencies despite passing basic quality tests? Do customers complain about performance issues even though your viscosity measurements look perfect? Complete quality control requires both rheological and viscosity data.

Quality control benefits from both measurements because viscosity provides quick, repeatable testing for production monitoring, while rheological testing offers deeper insights for troubleshooting and formulation refinement. Together, they ensure both consistency and performance, catching issues that either method alone might miss.

In our Martests laboratory, we regularly demonstrate the value of combined testing. A paint manufacturer from Brazil was experiencing inconsistent feedback from customers despite all batches passing their viscosity checks. Our comprehensive testing revealed significant variations in thixotropic recovery that affected application properties but wasn't captured in basic viscosity tests.

The complementary roles of these measurements include:

Viscosity Testing for Quality Control:

- Speed - Quick results for rapid production decisions

- Simplicity - Easier training for production personnel

- Repeatability - Highly consistent results for trend monitoring

- Cost-Effectiveness - Lower equipment and maintenance costs

- Historical Continuity - Compatibility with established specifications

Rheological Testing for Quality Control:

- Sensitivity - Detection of subtle formulation issues

- Performance Prediction - Better correlation with end-use properties

- Root Cause Analysis - Deeper insights for troubleshooting

- Structure Monitoring - Early detection of stability issues

- Process Optimization - Data for improving manufacturing efficiency

Many of our customers implement a tiered testing approach. They use rotational viscometers for regular production monitoring, then conduct more comprehensive rheological testing for new formulations, customer complaints, or periodic verification. This balanced approach optimizes both testing efficiency and product quality.

A notable example comes from one of our Southeast Asian clients in the adhesive industry. They established control charts using both viscosity measurements (for hourly production checks) and key rheological parameters (tested once per shift). This combined approach reduced customer complaints by 65% while keeping testing costs manageable.

For companies just beginning to implement rheological testing, I recommend starting with the most critical quality parameters for your specific application, then gradually expanding your testing capabilities as you recognize the value of more comprehensive data.

Conclusion

Viscosity is just one aspect of the broader field of rheology. While viscosity testing offers quick, simple measurements of flow resistance, rheological testing provides comprehensive material characterization that better predicts real-world performance across various conditions.