Measuring the viscosity of fluids is a fundamental task in industries ranging from pharmaceuticals and food production to petrochemicals and cosmetics. Among the many types of viscometers available, the cone and plate viscometer1 stands out for its precision, efficiency, and suitability for small sample volumes.

But what exactly is a cone and plate viscometer? Why is it preferred in so many laboratory and quality control environments? And how does its unique geometry contribute to more accurate rheological measurements?

In this article, we’ll explore the core principles behind cone and plate viscometers, how they differ from other viscosity measurement devices, and what makes them an essential tool for characterizing both Newtonian and non-Newtonian fluids. Whether you're a researcher, technician, or simply curious about fluid mechanics, this guide will provide a clear and comprehensive introduction to one of rheology’s most trusted instruments.

What Is a Cone and Plate Viscometer and How Does It Work?

Do your customers need precise measurements even with small samples? Inaccurate results can lead to wasted product and lost batches.

A cone and plate viscometer works by rotating a cone placed at a slight angle above a stationary flat plate. The fluid sample fills the small gap between them. This geometry ensures the shear rate is uniform throughout the sample, which is key for non-Newtonian fluids2.

Understanding the design helps explain its benefits. I see many distributors selling standard spindle viscometers, which are great for basic checks, but the cone and plate design serves a different need entirely. It's about controlled, consistent stress on the fluid.

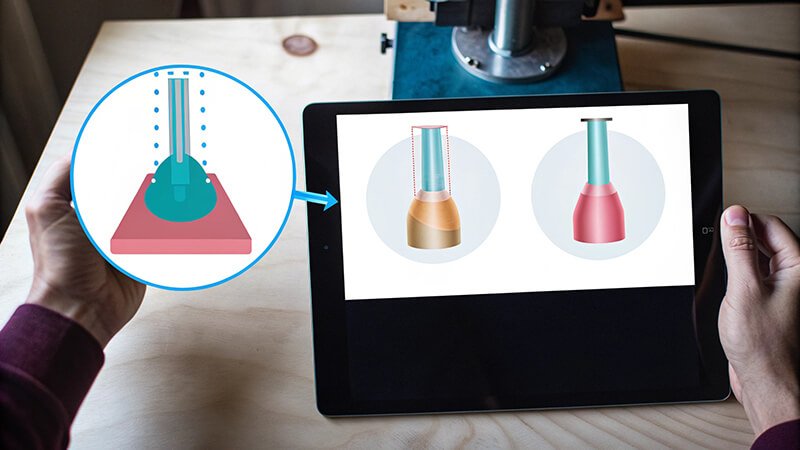

Geometry and Working Principle

The design uses a cone with a small angle, usually less than 1 degree, and a flat plate. The tip of the cone theoretically touches the plate center, or there is a tiny controlled gap. The fluid sample goes in this gap. The instrument rotates the cone at a set speed. It then measures the torque required to do this. This torque relates directly to the fluid's resistance to flow, which is its viscosity. My factory produces these parts to very tight tolerances because the angle and gap are critical. A slight error here means the shear rate3 is not uniform, and the measurement is wrong. Customers I talk to, like those distributing in Europe, value this precision highly.

Constant Shear Rate

The geometry ensures that the shear rate is constant everywhere in the sample. This is the main advantage over standard spindle viscometers. With spindles, the shear rate changes depending on how far the fluid is from the spindle's center or surface. For many industrial fluids, especially non-Newtonian ones, viscosity changes with shear rate. Getting a single, representative viscosity value requires knowing the shear rate you are applying. The cone and plate system provides this uniform shear rate, making the data much easier to interpret for complex fluid behavior.

Why Use a Cone and Plate Instead of Other Viscometers?

Are your current viscometers falling short for specific fluid types or sample sizes? Choosing the wrong tool leads to unreliable data.

Cone and plate viscometers offer advantages like small sample volume4, excellent temperature control, and the ability to measure viscosity at high, well-defined shear rates, unlike many other viscometer types such as standard spindle or capillary.

When talking to distributors, I often explain that adding a cone and plate model to their catalog opens up new markets. It's not just another viscometer; it's a solution for challenging applications that standard viscometers cannot handle well. Think about customers in cosmetics or pharmaceuticals.

Key Advantages

Cone and plate systems shine in several areas. First, they need only a tiny amount of sample, often less than 1 ml. This is great for expensive or scarce materials. Second, the plate is easy to heat or cool, giving excellent temperature control. This is vital because temperature greatly affects viscosity. Third, they can reach very high shear rates by increasing the cone's rotation speed. This is important for testing fluids under conditions similar to spraying, mixing, or pumping. I hear from distributors in Southeast Asia that these features are important for local manufacturers of coatings and inks.

Comparison with Other Types

| Feature | Cone and Plate Viscometer | Standard Spindle Viscometer | Capillary Viscometer |

|---|---|---|---|

| Sample Volume | Very small (0.5 - 2 ml) | Medium (10 - 500 ml) | Small (0.5 - 10 ml) |

| Shear Rate Control | Constant, well-defined | Varies across sample | Varies along capillary |

| Temperature Control | Excellent, precise | Good, usually bath-based | Good, usually bath-based |

| Suitable for | Non-Newtonian, high shear rates | Newtonian/Non-Newtonian | Low viscosity Newtonian |

| Cleaning Ease | Relatively easy | Moderate | Can be difficult |

This table shows why someone might choose a cone and plate model. For distributors focusing on specific industrial sectors, these differences are major selling points. My factory can supply all these types, but I help distributors identify which models suit their customer base best.

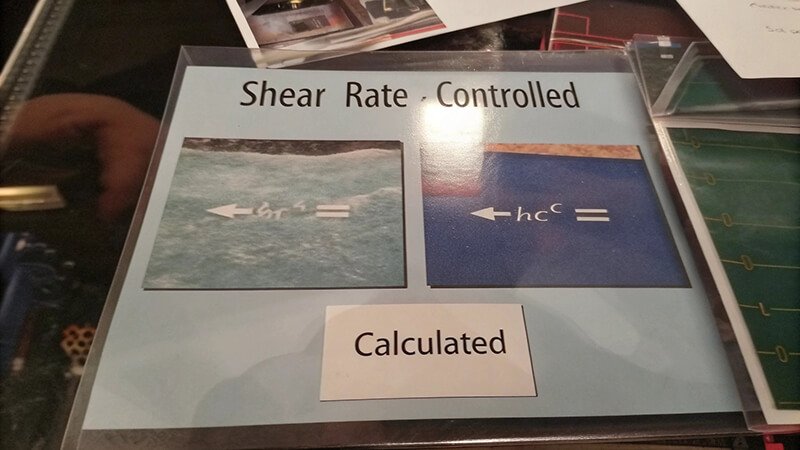

How Is Shear Rate Controlled and Calculated in This System?

Is calculating shear rate confusing with your current equipment? Knowing the exact shear rate is crucial for understanding fluid behavior.

In a cone and plate viscometer, the shear rate is controlled by the cone's rotational speed and the geometry (cone angle and plate diameter). The unique design makes the shear rate constant and easily calculable, simplifying analysis.

This ability to define and control shear rate is a core benefit. It is what allows users to get meaningful rheological data, not just a single viscosity number. I explain this to my customers because it adds significant value for their end-users doing R&D or detailed QC.

Geometry and Speed Relationship

The constant shear rate is a direct result of the cone's geometry and its position relative to the plate. As the cone spins, fluid layers between the cone and plate are sheared. The velocity gradient (how fast the fluid speed changes across the gap) divided by the gap size gives the shear rate. Due to the cone's angle, this ratio stays constant from the center to the edge of the plate. The rotational speed of the cone directly influences this velocity gradient. If the cone spins faster, the fluid is sheared more quickly, resulting in a higher shear rate. Slower speeds result in lower shear rates.

Calculation and Uniformity

The formula for shear rate in a cone and plate system is quite simple: it depends only on the cone's angular velocity and the angle of the cone. This calculation is built into the viscometer's software. What is powerful is that this calculated shear rate applies uniformly across the entire sample volume. Unlike other viscometers where shear rate varies, here every part of the sample experiences the same shearing force. This uniformity means the viscosity value measured is truly representative of the fluid's behavior at that specific shear rate. For customers doing detailed material characterization, this is indispensable. My engineers pay close attention to the cone geometry during manufacturing to ensure this uniformity is maintained.

What Types of Fluids Can Be Measured Using This Viscometer?

Do your customers work with complex non-Newtonian fluids? Standard viscometers often give misleading results for these materials.

Cone and plate viscometers are best suited for measuring moderate to high viscosity fluids, especially non-Newtonian ones like paints, gels, and polymers, where understanding flow behavior under defined shear conditions is necessary.

Helping distributors understand which fluids match this technology is key. While it is versatile, it is not perfect for every sample. I guide my customers on positioning this product for the right applications in their markets.

Newtonian vs. Non-Newtonian

Fluids behave differently when sheared. Newtonian fluids, like water or thin oils, have a viscosity that does not change with shear rate. Their viscosity is constant. Non-Newtonian fluids, like ketchup, paint, or yogurt, have viscosity that changes with shear rate. They might become thinner when stirred (shear-thinning, or pseudoplastic) or thicker (shear-thickening, or dilatant). Some also show time-dependent behavior (thixotropic or rheopectic). Cone and plate viscometers are excellent for non-Newtonian fluids because they allow you to measure viscosity at a specific, controlled shear rate. This helps characterize how the fluid will behave in real-world processes like pumping or spreading.

Suitable and Unsuitable Samples

Cone and plate systems are ideal for many industrial and consumer products. Think cosmetics (creams, lotions), paints and coatings, polymer solutions, adhesives, and certain food products (sauces, purees). These are often non-Newtonian. However, they are not ideal for fluids with large particles, like some slurries or composites. The particles can get stuck in the small gap between the cone and plate, affecting the measurement or even damaging the cone. Very low viscosity fluids might also be difficult to measure accurately due to the low torque involved. When I discuss options with distributors in the Middle East, where paint and construction materials are big, I highlight the cone and plate's fit for many paint types but also mention limitations for heavily filled samples.

What Are the Key Parameters and Settings to Consider?

Are inconsistent measurements frustrating your quality control? Small details in setting up a viscometer can have a big impact.

Accurate cone and plate measurements depend heavily on parameters like the cone angle, the gap between cone and plate, precise temperature control5, and using the correct sample volume. Setting these correctly is vital.

Getting good data requires attention to detail. I often remind my distributors' technical teams that user training on these points is critical. A great viscometer needs correct operation to perform well.

Influence on Accuracy

Several factors directly affect the accuracy of cone and plate measurements. The cone angle is fundamental; it is used in the shear rate calculation. Any error here means the calculated shear rate is wrong. The gap between the cone and plate must be set correctly, usually a tiny distance (micrometers) at the center. If the gap is too large, the shear rate is not uniform. Temperature is hugely important; even a few degrees difference can significantly change viscosity, especially for polymers or oils. The sample volume must be just enough to fill the gap without overflowing. Too little sample leaves gaps, too much is squeezed out unevenly.

Setting Up for Success

Proper setup starts with selecting the right cone for the viscosity range and desired shear rates. Then, calibrate the instrument and verify the gap setting. Temperature control needs to be stable and uniform across the plate. My viscometers often have built-in temperature control plates for this reason. Loading the sample carefully is next, avoiding air bubbles which can interfere with the flow. Finally, selecting the correct test method (e.g., single speed, shear rate sweep) based on the fluid type and what information is needed is important. Distributors selling to QC labs in South America tell me ease of use and reliable setup guides are big factors for their customers. My factory provides clear manuals and remote support to help with this.

What Are Common Challenges and How Can They Be Avoided?

Are your viscometer readings inconsistent or unreliable? Many issues come from common operational mistakes or lack of maintenance.

Common challenges with cone and plate viscometers include problems with sample loading (like air bubbles), maintaining stable temperature, ensuring proper cleaning, and confirming correct gap setting. Careful procedures can prevent most issues.

I help my distributors troubleshoot common problems. Many issues stem from simple things that can be avoided with good practice. Ensuring their customers get reliable results builds trust in the equipment.

Troubleshooting Steps

One frequent issue is sample loading. If you load the sample too quickly or use too much, you can trap air bubbles. Air pockets disrupt the flow and give false readings. To avoid this, load sample slowly from one side, letting it spread evenly. Another challenge is temperature stability. The sample volume is small, so its temperature can change quickly. Use the built-in temperature control system diligently and allow enough time for the sample to reach the set temperature before measuring. Cleaning is also crucial. Any residue from a previous sample will contaminate the new one and affect viscosity. Clean the cone and plate thoroughly after each test, using appropriate solvents. Finally, always check the gap setting calibration regularly. A bent cone or worn plate can alter the gap. My factory builds robust instruments, but regular checks are still needed for long-term accuracy. I advise distributors to offer service checks to their customers for this reason.

Where Is the Cone and Plate Viscometer Most Commonly Used?

Are you wondering which industries rely on this type of viscometer? Its specific strengths make it essential in many specialized fields.

Cone and plate viscometers are widely used in industries like cosmetics, paints and coatings, pharmaceuticals, and food, where precise control of shear conditions is needed for quality control and product development.

Knowing the typical applications helps distributors target the right customers. It shows where the cone and plate model provides unique value that other viscometers do not. I see strong demand from certain sectors globally.

Industry Applications

In cosmetics and pharmaceuticals, they are used for testing creams, lotions, gels, and ointments. Consistency, feel, and how the product spreads depend on rheology. For paints, inks, and coatings, cone and plate viscometers help predict how the material will behave during application (brushing, spraying) and drying. Polymer solutions and adhesives are tested to understand molecular weight and processing behavior. In the food industry, they analyze products like sauces, chocolate, or dairy to control texture and mouthfeel. These applications often involve non-Newtonian fluids and require specific shear rate data, making the cone and plate model ideal.

Lab vs. Quality Control

Cone and plate viscometers are used in both research and development (R&D) labs and quality control (QC) labs. In R&D, they help scientists develop new formulations by precisely measuring rheological properties under various conditions. They can run complex tests like shear rate sweeps to understand flow curves. In QC, they ensure consistency from batch to batch. They might measure viscosity at a specific shear rate relevant to the manufacturing process or end-use. While QC often uses simpler single-point tests, the precision and reliability of the cone and plate are still valuable. My factory produces models suitable for both, allowing distributors to serve a wide range of customers, from university labs to busy production floors.

Conclusion

Cone and plate viscometers offer precise, controlled measurements for complex fluids. They are vital for quality control and R&D in many industries.

-

Explore more about our cone and plate viscometer. ↩

-

Understanding non-Newtonian fluids is crucial for accurate measurements; this resource will clarify their properties and behaviors. ↩

-

Shear rate plays a vital role in fluid behavior, especially for non-Newtonian fluids. Discover more about its significance here. ↩

-

Learn why small sample volume is crucial for accurate viscosity measurements and how it can save resources in your applications. ↩

-

Learn how temperature control impacts viscosity measurements, crucial for achieving accurate results in your experiments. ↩