Struggling with tricky fluid viscosity? Inaccurate readings can ruin product quality. A cup and bob viscometer offers precise, reliable measurements for you.

A cup and bob viscometer is a device that measures fluid viscosity by placing the sample in the gap between an outer cup and an inner bob. One part rotates relative to the other, and the resulting torque or speed indicates viscosity.

Understanding this instrument better can really help your lab work. We at Martests believe in providing clear information. So, let's explore more about what makes these viscometers essential for many quality control processes. Read on to learn more.

What Exactly Defines a Cup and Bob Viscometer?

Confused by viscometer types? Some seem overly complex. A cup and bob type, however, offers a straightforward design for clear, accurate viscosity data you can trust.

A cup and bob viscometer, also known as a coaxial cylinder viscometer, measures viscosity by shearing a liquid sample contained in the annular space (gap) between a fixed outer cylinder (cup) and a rotating or oscillating inner cylinder (bob).

When we talk about a cup and bob viscometer, we are referring to a specific geometry used for rheological measurements. The "cup" is the outer cylinder, and the "bob" is the inner cylinder, often suspended from a torque-measuring device. The liquid sample fills the small, precisely defined space, called the annulus, between these two cylinders. The key idea is to create a well-defined shear field within the sample. Unlike some other viscometer types that might be good for quick checks, the cup and bob system is designed for more rigorous and accurate measurements. This is especially true for non-Newtonian fluids where viscosity changes with shear rate. At Martests, we emphasize robust designs. We know our customers, like Jacky in Italy who buys lab instruments, rely on consistent and precise results for their quality control and product formulation. This setup also allows for excellent temperature control. This is critical because viscosity is highly temperature-dependent.

What is the Fundamental Principle Behind a Cup and Bob Viscometer?

Unsure how viscometers work? The physics can seem daunting. But the core idea of a cup and bob is simple: resistance to flow under controlled conditions.

The fundamental principle involves applying a defined rotational motion to either the cup or the bob. The fluid's resistance (viscosity) to this motion creates a measurable torque on the stationary or driven part, which is then related to the viscosity.

The basic principle relies on the relationship between shear stress and shear rate. When one cylinder rotates relative to the other, the fluid in the gap is subjected to shear. Shear stress (τ) is the force per unit area required to shear the fluid. Shear rate (γ̇) is the velocity gradient across the gap. For many fluids, especially Newtonian fluids, the viscosity (η) is simply the ratio of shear stress to shear rate (η = τ/γ̇). In a cup and bob system, the applied rotation creates a known shear rate. Or, it creates a known shear stress, depending on the instrument mode. The instrument then measures the resulting torque (which is related to shear stress) or the resulting rotational speed (related to shear rate). By knowing the geometry of the cup and bob (their radii and length) and the measured parameters, the viscosity can be accurately calculated. This defined geometry is a major advantage. It allows for absolute viscosity measurements, not just relative ones. This precision is something we at Martests focus on for our instruments, ensuring top quality for our wholesale customers.

What are the Key Components of a Cup and Bob Viscometer?

Wondering what's inside a cup and bob viscometer? The parts seem technical. But understanding them helps you appreciate its precision and how it works for you.

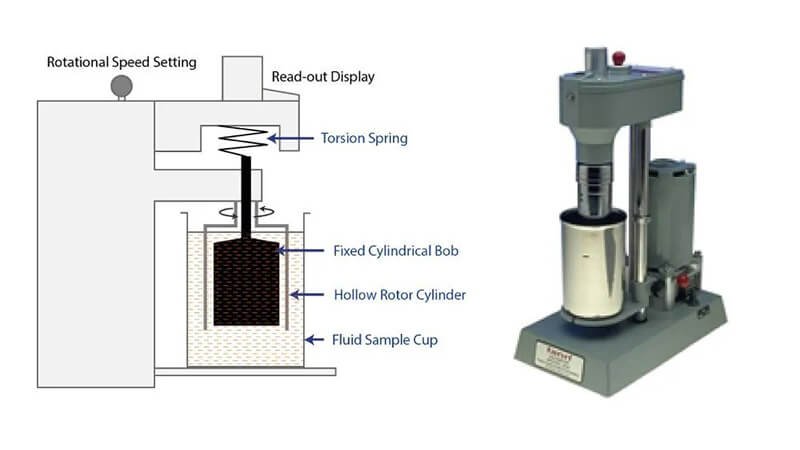

Key components include the outer cup holding the sample, the inner bob immersed in it, a drive mechanism to rotate one part, and a measurement system to detect torque or speed. These work together for accurate viscosity readings.

A cup and bob viscometer, while precise, is built from several core components that work in harmony. Let's look at them:

Outer Cylinder (Cup)

The cup is the stationary or rotating external cylinder that holds the liquid sample. Its dimensions are critical for accurate calculations. It often includes a jacket for temperature control. This is vital as viscosity is very sensitive to temperature changes. At Martests, we ensure our cups are made from durable materials for long life and easy cleaning. This is important for distributors who need to provide reliable products to their end-users.

Inner Cylinder (Bob)

The bob is the internal cylinder that is either rotated or suspended and measures torque. It's immersed in the sample within the cup. The geometry of the bob (e.g., cylindrical) and its surface finish are important design parameters. Different bob sizes can be used to measure different viscosity ranges. We can even customize logos on these parts for our B2B clients.

Drive Unit

This unit provides the rotational motion. It could be a motor that rotates the cup or the bob at a controlled speed. Or, it applies a controlled torque. The stability and precision of this drive are key to accurate measurements. Our manufacturing lines focus on assembling these units with high precision.

Measurement System

This system detects and quantifies the fluid's resistance. If a constant speed is applied, the system measures the resulting torque on the other cylinder. If a constant torque is applied, it measures the resulting rotational speed. This data is then used to calculate viscosity. Modern systems often have digital displays and data output, making them user-friendly for various lab environments.

How Does a Cup and Bob Viscometer Actually Work?

Curious about the actual process? It might seem like magic. But the working mechanism is a clear, step-by-step physical interaction, ensuring reliable fluid analysis.

The viscometer works by placing a sample between the cup and bob. One rotates, shearing the sample. The fluid's resistance creates a torque. This torque, or the speed at a set torque, directly relates to the sample's viscosity.

The operation of a cup and bob viscometer is a systematic process. First, the sample fluid is carefully loaded into the cup. This ensures the bob will be correctly immersed and the annular gap is properly filled. Any air bubbles must be avoided as they can lead to erroneous readings. Once the sample is in place and has reached thermal equilibrium (if temperature control is used), the test begins. In a common Searle-type system, the inner bob starts to rotate at a set speed. As the bob turns, it drags the fluid layers with it. This happens due to the fluid's internal friction, its viscosity. The stationary outer cup resists this motion. This resistance, or drag, creates a torque on the rotating bob. The viscometer's sensors measure this torque. The higher the viscosity of the fluid, the greater the resistance to flow. Therefore, the higher the torque required to maintain the set rotational speed. Conversely, in some instruments, a constant torque is applied. Then, the resulting rotational speed is measured. These measured values, along with the known geometric constants of the cup and bob, are then used by the instrument's software or through manual calculation to determine the viscosity. This direct measurement approach is why many purchasing managers prefer this type for their labs.

What are the Common Types of Cup and Bob Viscometers Available?

Are all cup and bob viscometers the same? It can be confusing. But there are two main types, each with specific operational differences for various needs.

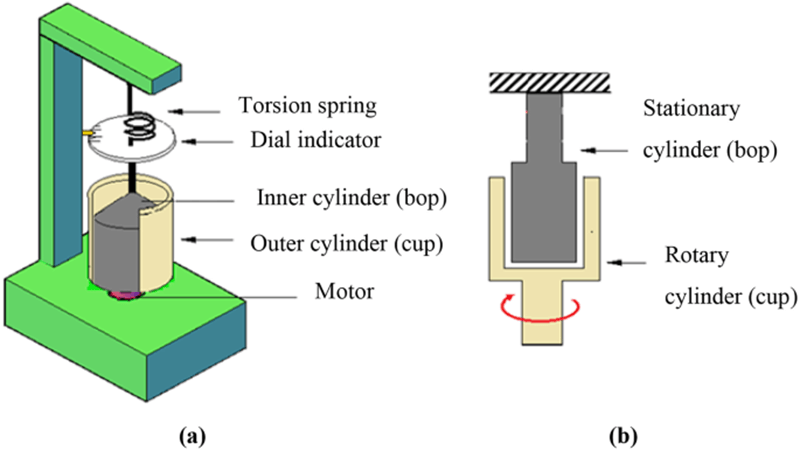

The two primary types are Couette, where the outer cup rotates and the inner bob measures torque, and Searle, where the inner bob rotates and the outer cup is fixed. Searle-type is more common in modern lab instruments.

While the basic principle is similar, cup and bob viscometers primarily fall into two categories based on which cylinder rotates:

Couette Type

In a Couette type viscometer, the outer cylinder (the cup) rotates at a constant angular velocity. The inner cylinder (the bob) is suspended by a torsion wire or an equivalent torque sensor. It remains stationary or nearly stationary. The viscous drag of the fluid sample, caused by the rotating cup, transmits a torque to the inner bob. This torque is then measured. From this, the viscosity is calculated. This design can be advantageous for studying flow instabilities like Taylor vortices. However, it can be more complex to implement precise temperature control directly on the rotating cup. This type is less common in general lab settings but has its place in specific research.

Searle Type

The Searle type is more common in many laboratory viscometers. This includes those we focus on at Martests. In this configuration, the inner cylinder (the bob) rotates at a constant angular velocity. The outer cylinder (the cup) remains stationary. The torque required to rotate the bob at this constant speed is measured. Alternatively, a constant torque is applied to the bob, and its resulting angular velocity is measured. The Searle design often simplifies sample handling and temperature control. The stationary cup can be easily jacketed. It's generally preferred for routine viscosity measurements and quality control applications. This is due to its practicality and ease of use, which customers like Jacky, who sources from China, appreciate.

What are the Main Advantages of Using a Cup and Bob Viscometer?

Why choose a cup and bob? Other methods exist. But this type offers distinct benefits in accuracy, control, and suitability for complex fluids, making it a top choice.

Advantages include well-defined shear conditions, suitability for a wide viscosity range, good temperature control, and the ability to measure non-Newtonian fluids accurately. This makes them highly reliable for many applications.

Cup and bob viscometers offer several significant advantages. This is why they are widely used in both research and industrial quality control.

One major benefit is the well-defined shear geometry. The narrow gap between the cup and bob creates a relatively uniform shear rate across the sample. This is crucial for accurate characterization of non-Newtonian fluids. Their viscosity changes with shear rate. This allows for absolute viscosity measurements.

Secondly, they are suitable for a wide range of viscosities. They can measure from very low to very high viscosities. This is often achieved by simply changing the bob size or rotational speed.

Thirdly, excellent temperature control is usually possible. The cup can often be jacketed for precise temperature regulation. This is vital because viscosity is highly temperature-dependent. We at Martests know that consistent temperature is key for our customers in Europe and Southeast Asia who demand reliable data.

Furthermore, they can characterize time-dependent behavior. This includes thixotropy (shear thinning over time) or rheopexy (shear thickening over time).

Finally, their robust construction and ability to handle various sample types, including suspensions and emulsions, make them versatile tools. These advantages often outweigh the slightly more complex setup compared to simpler viscometers like falling ball or capillary types for many demanding applications.

In Which Fields are Cup and Bob Viscometers Most Commonly Applied?

Where are these used? Their precision seems specialized. But cup and bob viscometers are vital in many industries, ensuring quality from food to pharmaceuticals.

They are widely used in industries like paints, coatings, food products, cosmetics, pharmaceuticals, petroleum, and chemicals. They help in quality control, R&D, and process optimization by measuring fluid flow behavior.

The versatility and accuracy of cup and bob viscometers make them indispensable across a broad spectrum of industries. In the paints and coatings industry, they are used to ensure proper consistency for application and final film properties. For food products, like sauces, dairy, and batters, viscosity control is key for texture, mouthfeel, and processability. The cosmetics and personal care industry relies on them for formulating creams, lotions, and shampoos with desired flow characteristics. In pharmaceuticals, they are crucial for developing liquid medications, ointments, and controlling manufacturing processes. The petroleum industry uses them for characterizing crude oils and lubricating oils. In the chemical industry, they are vital for monitoring polymerization reactions and ensuring the quality of various chemical products. At Martests, we see demand from distributors supplying all these sectors from our main export regions like the Middle East and South America. Our clients, like Jacky who resells lab instruments with his own logo, value viscometers that can meet diverse customer needs. Essentially, any industry dealing with fluids where flow behavior is critical will likely use some form of cup and bob viscometer for research, development, or quality assurance.

Conclusion

Cup and bob viscometers are vital for precise viscosity analysis. They help many industries ensure product quality. We at Martests are proud to provide these essential instruments.