Understanding the flow and deformation of materials is essential in a wide range of industries, from pharmaceuticals and food production to polymers and cosmetics. At the heart of this exploration lies a powerful scientific instrument: the rheometer.

Rheometers are designed to measure the rheological properties of substances—how they respond to applied forces. Unlike simple viscometers, which only measure viscosity, rheometers provide deeper insight into a material’s viscoelastic behavior, yield stress, thixotropy, and other complex characteristics.

This article introduces the fundamentals of rheometers, their working principles, types, and the critical role they play in material science and industrial quality control. Whether you're a researcher, engineer, or quality analyst, gaining a basic understanding of rheometers is key to unlocking the behavior of complex fluids and soft solids.

What is a Rheometer?

Does the word "rheometer" sound intimidatingly technical? If you think it's just another complicated lab device, you might miss out on its powerful capabilities for material characterization.

A rheometer is an instrument used to measure the rheological properties of materials – essentially, how they flow and deform. It applies a controlled stress or strain and measures the resulting deformation or stress.

A rheometer is a sophisticated tool that goes beyond simple viscosity measurements. "Rheology" is the science of the deformation and flow of matter. So, a rheometer is a device specifically designed to study these properties. While a viscometer might tell you how "thick" a liquid is under one or a few conditions, a rheometer can tell you how its thickness changes with flow, or if it has solid-like properties such as elasticity.

At Martests, we often explain to clients that a rheometer works by subjecting a sample material to a defined mechanical stress (force per area) or strain (deformation). It then measures the sample's response: if stress is applied, it measures the resulting strain or strain rate; if strain is applied, it measures the stress required. This allows for a detailed characterization of:

- Viscosity: Resistance to flow, but measured over a wide range of shear rates or temperatures.

- Elasticity: The ability of a material to return to its original shape after deformation (like a solid).

- Viscoelasticity: Materials that exhibit both viscous (liquid-like) and elastic (solid-like) characteristics. Many common materials, like creams, gels, and polymer melts, are viscoelastic.

Essentially, a rheometer provides a much more complete picture of a material's mechanical properties compared to a basic viscometer.

Why is Rheometry Important?

Think rheology is just for academic research? Ignoring it can lead to product failures, inefficient processing, and missed innovation opportunities in many industries.

Rheometry is important because it helps predict how materials will behave during processing, application, and storage. This ensures product quality, optimizes manufacturing, and drives new product development.

The data a rheometer provides – a material's rheological profile – is incredibly valuable for many reasons. I’ve seen companies like Jacky's in Italy, who distribute lab instruments, explain these benefits to their customers. Understanding rheology can be the key to solving tricky problems or creating superior products.

Here's why it's so important:

- Product Development & Formulation: When creating new products, like cosmetics, food items, or pharmaceuticals, their texture, stability, and performance are often directly linked to their rheological properties. For example, a lotion needs to flow easily from a bottle but not be too runny on the skin. A rheometer helps formulators achieve these desired characteristics.

- Process Optimization: How a material behaves during manufacturing processes like pumping, mixing, spraying, coating, or molding is crucial. Rheological data can help engineers design better processes, predict potential problems (like blockages in pipes), and ensure consistent production.

- Quality Control (QC): Once a product is developed, rheometry can be used as a QC tool to ensure that each batch meets the specified rheological fingerprint. This guarantees consistency in product quality and performance, which is vital for customer satisfaction and brand reputation.

- Predicting End-Use Performance: How will a paint level on a wall? How will an adhesive bond? How will a drilling mud perform downhole? Rheological measurements can help predict these and many other end-use behaviors.

- Fundamental Material Understanding: For scientists and researchers, rheometers are essential tools for understanding the microstructure of materials and how this relates to their macroscopic properties.

At Martests, we emphasize that rheometry isn't just about numbers; it's about gaining actionable insights that can lead to better products and more efficient operations.

How Does a Rheometer Work?

Does a rheometer seem like a black box that spits out data? Not understanding its basic working principles can make it harder to interpret results or trust the instrument.

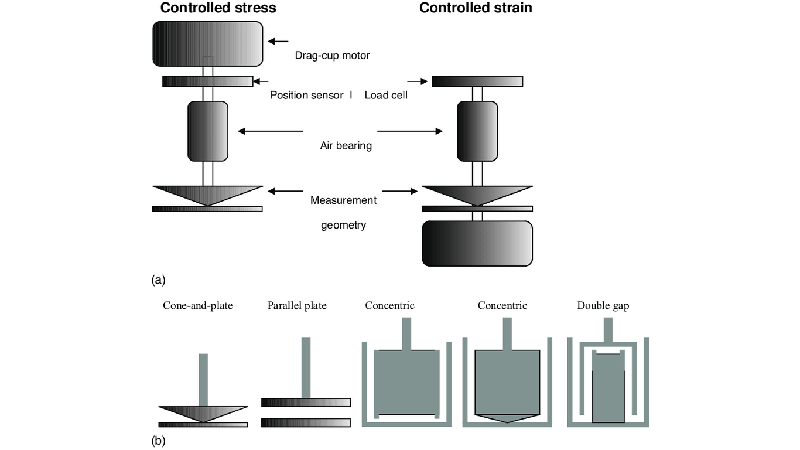

A rheometer typically works by placing a sample between two geometries. One geometry moves (rotates or oscillates) under controlled stress or strain, while the other measures the resulting torque or displacement.

The basic principle behind most rheometers is quite elegant. Imagine you have a small amount of your material. The rheometer will confine this material in a precisely defined space, usually between two surfaces or "geometries."

Here's a breakdown of the core components and process:

- Sample Loading: The material is placed between the measuring geometries. Common geometries include parallel plates, cone and plate, or concentric cylinders (cup and bob). The choice depends on the sample type and the test.

- Applying Force/Deformation: A highly precise motor is used to apply a controlled mechanical action. This can be:

- Rotation: One geometry rotates at a defined speed (controlled shear rate) or with a defined torque (controlled shear stress).

- Oscillation: One geometry oscillates back and forth at a defined frequency and amplitude. This is key for studying viscoelasticity.

- Measuring the Response: Sensors detect the material's reaction.

- If a controlled shear rate (speed) is applied, the instrument measures the torque (rotational force) needed to maintain that rate. This torque is then converted to shear stress.

- If a controlled shear stress (torque) is applied, the instrument measures the resulting rotational speed, which is converted to shear rate.

- In oscillatory tests, the instrument measures both the magnitude of the response and any phase lag between the applied motion and the material's response. This phase lag tells us about the elastic vs. viscous nature.

- Temperature Control: Most modern rheometers have precise temperature control systems because rheological properties are often very sensitive to temperature.

From these applied actions and measured responses, the rheometer's software calculates various rheological parameters, such as viscosity, shear stress, shear rate, storage modulus (G'), loss modulus (G''), and tan delta (δ). These parameters paint a detailed picture of the material's behavior.

What Kinds of Rheometers Are There?

Overwhelmed by the different rheometer types available? Choosing one without knowing the categories could mean getting an instrument that doesn't fit your specific needs.

Common rheometers include rotational (for shear and viscoelasticity), capillary (high shear rates), and extensional rheometers (stretching flows). Specialized types exist for specific applications like interfacial rheology.

While the basic principle of applying stress/strain and measuring response is common, rheometers come in various designs, each suited for different types of materials or measurements. Here are some main categories:

- Rotational Rheometers:

- Description: These are perhaps the most versatile and widely used. They typically use geometries like cone-and-plate, parallel plates, or concentric cylinders (cup and bob).

- Best for: Measuring shear viscosity over a wide range of shear rates, yield stress, thixotropy, and viscoelastic properties (G', G'') through oscillatory tests. Ideal for liquids, dispersions, gels, polymer solutions, and melts. Many of our Martests clients in diverse industries use this type.

- Capillary Rheometers:

- Description: In these, the fluid is forced through a capillary (a narrow tube) of known dimensions under a controlled pressure or flow rate.

- Best for: Measuring viscosity at very high shear rates, often encountered in processes like injection molding or extrusion of polymer melts. They are less suited for very low viscosity fluids or for detailed viscoelastic characterization.

- Extensional Rheometers:

- Description: These measure a material's resistance to stretching or extensional deformation, which is different from shear deformation.

- Best for: Applications where extensional flow is dominant, such as fiber spinning, film blowing, foaming, or inkjet printing.

- Specialized Rheometers:

- Interfacial Rheometers: Designed to measure the rheological properties of surfaces and interfaces (e.g., between two immiscible liquids or a liquid and air). Crucial for emulsions and foams.

- Powder Rheometers: Specifically designed to characterize the flow properties of powders and granular materials.

The choice depends heavily on the material to be tested and the information sought. For instance, a cosmetics company formulating a cream would likely use a rotational rheometer, while a polymer manufacturer testing melt processability might use a capillary rheometer.

Where Are Rheometers Used?

Think rheometers are confined to niche research labs? You might be surprised by their widespread use across many major industries, impacting everyday products.

Rheometers are used in polymers, food, pharmaceuticals, cosmetics, paints, coatings, adhesives, and the petroleum industry for R&D, quality control, and process optimization.

Rheometers are not just academic tools; they are workhorses in many industries, helping to develop, manufacture, and ensure the quality of countless products we use daily. At Martests, we see demand from distributors who supply these varied sectors. Here are some key application areas:

- Polymers and Plastics:

- Characterizing melt flow behavior for injection molding, extrusion, and film blowing.

- Determining viscoelastic properties for predicting sag, warp, or processing stability.

- QC of incoming resin batches.

- Food Industry:

- Optimizing texture (e.g., creaminess of yogurt, spreadability of butter, mouthfeel of sauces).

- Ensuring stability of emulsions (mayonnaise) and suspensions (chocolate milk).

- Controlling pumping and filling processes.

- Pharmaceuticals:

- Formulating creams, ointments, and gels with desired consistency and spreadability.

- Ensuring stability and redispersibility of suspensions and emulsions.

- Characterizing injectability of parenteral drugs.

- Studying mucoadhesion for drug delivery.

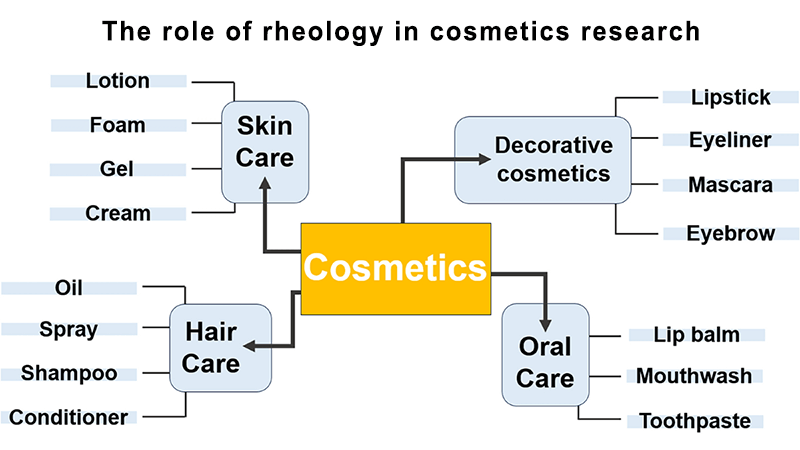

- Cosmetics and Personal Care:

- Developing lotions, creams, and shampoos with appealing texture and application properties.

- Ensuring stability of formulations over shelf life.

- Controlling the flow of products like lipstick or mascara during application.

- Paints, Coatings, and Inks:

- Optimizing brushability, sprayability, leveling, and sag resistance.

- Ensuring stability during storage and application.

- Controlling pigment dispersion and preventing settling.

- Adhesives and Sealants:

- Characterizing curing behavior.

- Determining tack, peel strength, and flow properties for application.

- Petroleum Industry:

- Characterizing drilling muds for optimal performance under pressure and temperature.

- Analyzing the flow properties of crude oil and bitumen.

The insights from rheometers directly impact product performance, consumer experience, and manufacturing efficiency in these fields.

How Do I Choose the Right Rheometer?

Facing a rheometer purchase and feeling lost in the options? Choosing without clear criteria can lead to an expensive instrument that doesn't meet your actual testing needs.

To choose the right rheometer, consider your sample types (viscosity, volume), required measurements (viscosity, G', G''), operating conditions (temperature, pressure), ease of use, and budget.

Selecting the right rheometer is a critical decision. It’s an investment, so you want to make sure it meets your current and potential future needs. As we advise our Martests partners, here are key factors to consider:

- Sample Characteristics:

- Viscosity Range: Will you be testing low-viscosity fluids (like solvents), high-viscosity pastes, or solids? Different rheometers have different torque and sensitivity ranges.

- Sample Volume: Some techniques require more sample than others.

- Nature of Sample: Is it a simple liquid, a suspension with particles, an emulsion, a gel, a polymer melt, or a powder? This will influence geometry choice and instrument type.

- Reactivity/Volatility: Do you need sealed geometries or solvent traps?

- Measurement Needs:

- What properties are you interested in? Simple flow curves (viscosity vs. shear rate)? Yield stress? Thixotropy? Or more complex viscoelastic parameters like G', G'', and tan delta from oscillation tests? Creep and stress relaxation?

- Shear Rate Range: Do you need very low shear rates (simulating storage) or very high shear rates (simulating processing)?

- Operating Conditions:

- Temperature Range: What temperatures will your samples experience during processing or use? The rheometer needs an appropriate temperature control system (e.g., Peltier, fluid bath, oven).

- Pressure: Some applications require measurements under high pressure.

- Atmosphere: Do you need to control the atmosphere (e.g., inert gas)?

- Ease of Use and Software:

- How user-friendly is the instrument and its control/analysis software?

- Is automation important for high throughput?

- Budget and Support:

- Rheometers range significantly in price. Define your budget.

- Consider the availability of technical support, service, and application expertise from the supplier.

I always tell people it's wise to discuss your specific applications with experts or manufacturers. They can help guide you to the most suitable instrument.

Conclusion

Rheometers are powerful tools for understanding material flow and deformation. They are vital for R&D, QC, and process optimization across numerous industries, driving innovation and quality.