Are you struggling to get consistent and accurate viscosity measurements? Many lab managers face this challenge daily, leading to quality control issues and production delays. A rotational viscometer could be your solution.

A rotational viscometer is a precision instrument that measures fluid viscosity by rotating a spindle in the sample and measuring the torque required to maintain a constant rotation speed. This provides accurate viscosity data for quality control and research applications.

As someone who has manufactured viscometers for over 15 years, I've helped countless labs optimize their viscosity testing. Let me share the essential knowledge you need about these vital instruments.

What Is the Principle of a Rotational Viscometer?

Getting accurate viscosity measurements can feel like a mystery. Without understanding the core principles, you might waste time with incorrect readings and questionable data.

Rotational viscometry measures the resistance encountered by a rotating element as it moves through a fluid. The resistance of the fluid to this rotational motion directly correlates to its viscosity - higher resistance means higher viscosity.

The principle behind rotational viscometry is based on fluid mechanics fundamentals. When a spindle element in a fluid, it creates a shearing action between layers of the fluid. The instrument measures this shear stress and correlates it to viscosity through precise calibration.

Key Components

- Motor system: Provides controlled rotation

- Measuring rotating element: Creates fluid shear

- Torque sensor: Measures fluid resistance

- Temperature control: Maintains sample conditions

- Digital display: Shows measured values

Modern rotational viscometers use sophisticated electronics to ensure measurement accuracy within ±1% of the full scale range. This level of precision makes them ideal for quality control applications across industries.

How Is Viscosity Calculated?

Many users struggle with understanding viscosity calculations, leading to confusion about their measurements. Let's break down this complex topic into simple terms.

Viscosity is calculated by measuring shear stress1 (force per unit area) and shear rate2 (velocity gradient). The ratio of shear stress to shear rate gives us dynamic viscosity3, typically measured in Pascal-seconds (Pa·s) or centipoise (cP).

Understanding viscosity calculations requires familiarity with several key concepts:

Fundamental Equations

| Parameter | Formula | Units |

|---|---|---|

| Shear Stress (τ) | F/A | Pascal (Pa) |

| Shear Rate (γ) | v/h | Second⁻¹ (s⁻¹) |

| Viscosity (η) | τ/γ | Pa·s or cP |

The relationship between these parameters follows Newton's law of viscosity4 for Newtonian fluids. However, many industrial fluids are non-Newtonian, meaning their viscosity changes with shear rate. This is why modern rotational viscometers can measure at multiple speeds to characterize complex fluid behavior.

What Types of Rotational Viscometers Are Available?

Choosing the wrong type of viscometer can lead to inaccurate results and wasted investment. Understanding the available options is crucial for making an informed decision.

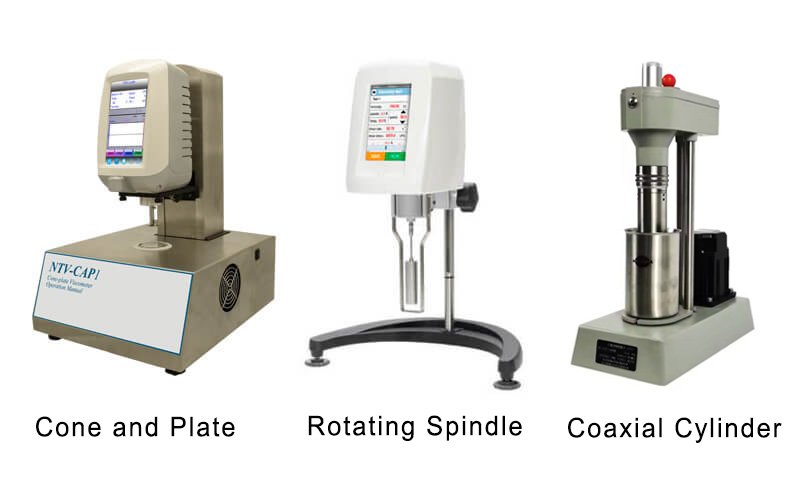

There are three main types of rotational viscometers: coaxial cylinder Viscometers5, cone and plate Viscometes, and rotating spindle viscometers. Each type is designed for specific applications and viscosity ranges, offering different advantages in terms of sample volume and measurement accuracy.

Let's examine each type in detail:

Comparison of Rotational Viscometer Types

| Type | Sample Volume | Accuracy | Best For |

|---|---|---|---|

| Coaxial Cylinder Viscometers | Large (>16ml) | Very High | Low to medium viscosity |

| Cone and Plate Viscometers | Small (<1ml) | Highest | Research & Development |

| Rotating Spindle Viscometers | Medium | Good | Production QC |

Each type has specific advantages and limitations. For instance, rotating spindle viscometers are popular in production environments due to their robustness and ease of use, while cone and plate systems are preferred in research settings where precise temperature control and small sample volumes are crucial.

How to Select the Right Rotational Viscometer?

With so many options available, selecting the right viscometer can feel overwhelming. Making the wrong choice could cost you thousands in wasted investment and unreliable results.

Choose a rotational viscometer based on your sample's expected viscosity range, required accuracy, sample volume, temperature control needs, and testing environment. Consider also your budget and whether you need advanced features like programmable testing sequences.

Key Selection Criteria

-

Measurement Range Requirements

- Low viscosity (<100 cP): Consider coaxial cylinder systems

- Medium viscosity (100-100,000 cP): Standard rotating spindle models

- High viscosity (>100,000 cP): Special high-torque models

-

Operating Environment Considerations

| Factor | Impact | Recommendation |

|---|---|---|

| Temperature | Affects accuracy | Choose models with temperature control |

| Vibration | Disturbs readings | Select stable mounting options |

| Sample Volume | Testing flexibility | Match to available sample sizes |

| Automation Needs | Efficiency | Consider programmable models |

Based on my experience manufacturing viscometers, I've found that many customers initially focus too much on price while overlooking crucial factors like service support and calibration requirements. A slightly higher investment in a more suitable model often pays off through better reliability and accuracy.

What Is the Test Procedure for a Rotational Viscometer?

Improper testing procedures can lead to inconsistent results and damaged equipment. Follow these steps for reliable measurements.

A proper viscosity test involves six key steps: sample preparation, temperature equilibration, spindle selection, speed setting, measurement, and cleaning. Each step must be performed carefully to ensure accurate and repeatable results.

Detailed Test Procedure

- Sample Preparation

- Allow sample to reach room temperature

- Mix thoroughly but avoid air bubbles

- Check sample volume requirements

- Temperature Control

- Set desired temperature

- Wait for stability (typically 10-15 minutes)

- Spindle Selection

| Viscosity Range | Recommended Spindle |

|---|---|

| <100 cP | UL adapter |

| 100-10,000 cP | #2 or #3 spindle |

| >10,000 cP | #4 or #5 spindle |

- Speed Selection

- Measurement Process

- Cleaning and Maintenance

What Factors Affect the Accuracy of Rotational Viscometer Measurements?

Achieving accurate measurements can be challenging if you're not aware of potential error sources. Understanding these factors is crucial for reliable results.

Key factors affecting measurement accuracy include temperature control, sample preparation, spindle selection, measurement speed, instrument calibration, and operator technique. Environmental conditions like vibration can also impact results.

Critical Factors to Control

- Temperature Effects

- ±1°C change can affect viscosity by 2-10%

- Use temperature-controlled systems

- Sample Handling

- Avoid air bubbles

- Maintain consistent sample volume

- Equipment Factors

| Factor | Impact | Solution |

|---|---|---|

| Calibration | Baseline accuracy | Regular verification |

| Spindle condition | Data consistency | Inspect for damage |

| Level adjustment | Measurement stability | Check before each use |

Which Industries Use Rotational Viscometers?

Each industry has unique viscosity measurement needs. Understanding these applications helps in selecting the right equipment.

Rotational viscometers are widely used in food and beverage, chemical, pharmaceutical, cosmetic, petroleum, and construction industries. Each sector has specific requirements for viscosity control in their production processes.

Industry-Specific Applications

| Industry | Applications | Typical Products |

|---|---|---|

| Food & Beverage | Quality Control | Sauces, dairy products |

| Pharmaceutical | R&D, Production | Liquid medicines, creams |

| Chemical | Process Control | Polymers, adhesives |

| Petroleum | Quality Testing | Oils, lubricants |

What Are the Advantages and Limitations?

After supplying viscometers to diverse industries for over 15 years, I've gained deep insights into their real-world performance strengths and limitations.

Rotational viscometers offer advantages like easy operation, wide measurement range, and good repeatability. However, they have limitations including sample size requirements, temperature sensitivity, and potential issues with non-Newtonian fluids6.

Detailed Analysis

Advantages

- Operational Benefits

- Simple to use and maintain

- Quick measurements

- Good repeatability

- Technical Strengths

| Feature | Benefit |

|---|---|

| Wide range | Measures 1-40M cP |

| Versatility | Multiple spindle options |

| Data handling | Digital recording |

Limitations

- Physical Constraints

- Minimum sample volume needed

- Temperature sensitivity

- Clean-up requirements

- Technical Limitations

| Limitation | Impact |

|---|---|

| Non-Newtonian fluids | Complex analysis needed |

| Thixotropic samples | Time-dependent changes |

| High-shear testing | May need special models |

How to Maintain and Calibrate Your Viscometer?

Poor maintenance can lead to inaccurate readings and expensive repairs. Based on our service department's experience, here's what you need to know.

Regular maintenance includes daily cleaning, periodic calibration checks, and professional servicing annually. Calibration should use certified standard oils and follow manufacturer guidelines for specific procedures.

Maintenance Schedule

- Daily Tasks

- Clean spindles thoroughly

- Check level adjustment

- Inspect for damage

- Monthly Tasks

| Task | Purpose |

|---|---|

| Calibration check | Verify accuracy |

| Bearing inspection | Prevent wear |

| Software updates | Ensure functionality |

- Annual Tasks

- Professional calibration

- Complete system check

- Parts replacement if needed

Calibration Procedure

- Preparation

- Gather calibration oils

- Clean equipment thoroughly

- Stabilize temperature

- Verification Steps

- Check zero point

- Test with standard oils

- Document results

Conclusion

Rotational viscometers are versatile instruments essential for quality control across industries. Success with these devices depends on proper selection, careful operation, and regular maintenance. By understanding their capabilities and limitations, you can ensure accurate measurements and reliable results for your specific applications.

-

Shear stress is a fundamental concept in fluid mechanics. Learning more about it can enhance your understanding of fluid behavior. ↩

-

Shear rate plays a vital role in determining fluid flow characteristics. Discover more about its significance in this resource. ↩

-

Understanding dynamic viscosity is crucial for various applications in fluid mechanics and engineering. Explore this link to deepen your knowledge. ↩

-

Understanding Newton's law of viscosity is crucial for grasping fluid dynamics and its applications in various industries. ↩

-

Learn about the working principles and benefits of coaxial cylinder viscometers for accurate viscosity measurement. ↩

-

This link will help you grasp the complexities of measuring viscosity in non-Newtonian fluids, which is essential for many industrial applications. ↩