Materials behaving unpredictably? This causes costly production problems. It's not just viscosity; it's rheology. Understanding the basics gives you control over your product's performance.

Rheology is the science of how materials deform and flow. It studies the relationship between stress, strain, and time. This knowledge is crucial for controlling how liquids, semi-solids, and even soft solids behave during processing, application, and storage.

Rheology might sound complex, but it's a field I deal with every day at Martests. My customers, like Jacky from Italy, don't just buy a viscometer; they buy a solution to a material problem. To find the right solution, we must first understand the problem itself. This starts with the fundamental concepts of rheology. Let's break it down into simple, manageable parts to see how it can help your business.

Why is an Introduction to Rheology Important?

Do terms like 'viscous' and 'rheometer' seem confusing? You need to understand them to choose the right equipment. Choosing the wrong instrument wastes money and gives useless data.

Rheology is the study of flow and deformation. Viscous behavior describes a fluid's resistance to flow, like honey. Rotational viscometers measure this. Oscillatory rheometers measure more complex viscoelastic properties, providing deeper insights into material structure using specific geometries.

When a client contacts me, our first discussion is always about their application. Understanding the basics of rheology is the first step to choosing the right tool for the job. It's the difference between buying a machine and solving a problem.

Rheology and Viscous Behavior

Viscosity is a term most people know. It’s a fluid's resistance to flow. Water has a low viscosity, while honey has a high viscosity. This is the most basic part of rheology. But rheology goes deeper. It also explains why ketchup is thick in the bottle but flows easily when you shake it. This change in viscosity is a rheological property. Viscous behavior is just one piece of the puzzle that rheology helps us solve.

Rotational Viscometers, Oscillatory Rheometers, and Measuring Geometries

We use specific instruments to measure these properties. For simple viscous behavior, a rotational viscometer is perfect. At Martests, we manufacture these instruments. They work by rotating a spindle in the fluid and measuring the torque (rotational force) required. This gives a clear picture of the fluid's viscosity. We offer different types, like rotating spindle viscometers, cone and plate viscometers, and cup and bob viscometers. Each is suited for different materials.

For more complex materials, an oscillatory rheometer is used. It can rock a sample back and forth to measure both solid-like and liquid-like properties. The choice of measuring geometry—like a cone and plate or a cup and bob—is also critical. It ensures the measurement is accurate for that specific sample type.

How Do Rotational Tests Measure Viscosity?

Are you just getting a single viscosity number? This number might not tell the whole story about your fluid. This can lead to incorrect assumptions about performance during application.

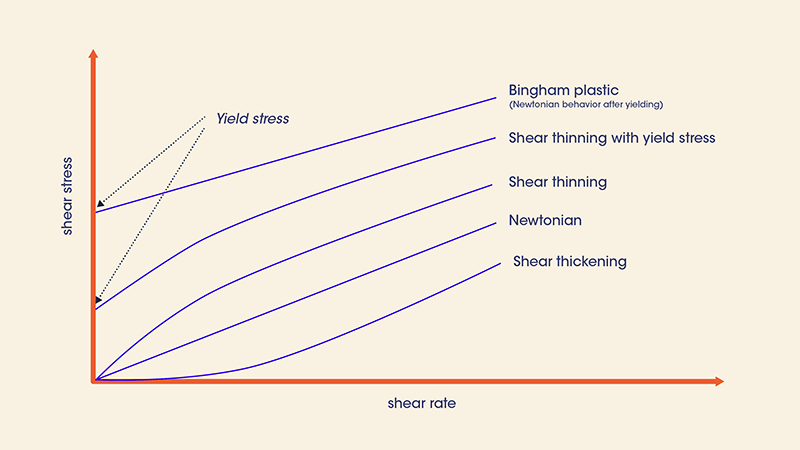

Rotational tests apply a controlled force (shear stress) to a fluid and measure its resulting flow speed (shear rate). The relationship between these two gives the viscosity. A flow curve plots stress versus rate, revealing if the fluid is Newtonian or non-Newtonian.

The rotational viscometers we produce at Martests are designed to perform these tests precisely. They give our clients the data they need to understand their materials completely, not just a single, often misleading, data point. Let's look at the terms and concepts behind these tests.

Rotational Tests and Key Terms

In a rotational test, we control the speed of a spindle and measure the torque, or we apply a specific torque and measure the speed. This action creates shear within the fluid.

- Shear Stress (τ): This is the force you apply over a certain area to make the fluid flow. Think of it as the 'push' on the liquid.

- Shear Rate (γ̇): This is the speed at which the fluid deforms or flows in response to the stress. It's a measure of how fast things are moving.

- Law of Viscosity: The fundamental relationship is simple: Viscosity (η) = Shear Stress / Shear Rate. Our instruments measure stress and rate to calculate viscosity.

- Kinematic Viscosity: This is the dynamic viscosity (η) divided by the fluid's density (ρ). It's important for processes where gravity drives the flow, like pouring or draining.

Flow Behavior and Measurement Approaches

The most useful output from a rotational test is a flow curve or viscosity curve. This shows how viscosity changes as you apply more force.

| Flow Behavior | Description | Example |

|---|---|---|

| Newtonian | Viscosity is constant, regardless of shear rate. | Water, oils, solvents |

| Shear-thinning | Viscosity decreases as shear rate increases. | Paint, ketchup, lotions |

| Shear-thickening | Viscosity increases as shear rate increases. | Cornstarch in water, some industrial slurries |

For a customer like Jacky, who resells paint, this is critical. He needs paint that is shear-thinning. It should be thick in the can (high viscosity at low shear) so it doesn’t drip, but thin out when a brush applies force (low viscosity at high shear) for easy application. A rotational test provides this exact information.

What Can Oscillation Tests Tell Us About Viscoelasticity?

Does your material act like both a solid and a liquid? Simple viscosity tests can't capture this behavior. You might miss crucial properties like elasticity, gel strength, or internal structure.

Oscillation tests measure a material's response to small, rapid deformations. They quantify both its ability to store energy like a solid (storage modulus, G') and its ability to flow like a liquid (loss modulus, G"). This is key for gels, polymers, and emulsions.

While Martests focuses on top-quality rotational viscometers, I always believe in educating my clients about the full scope of rheology. Sometimes, their material problems are more complex and require understanding viscoelasticity, which is measured by more advanced oscillatory rheometers.

Viscoelastic Behavior and Key Terms

Many materials, like gels, creams, and polymers, are viscoelastic. They have both a viscous (liquid-like) and an elastic (solid-like) component. Think of dough: it flows, but it also springs back.

- Shear Strain (γ): This is the amount of deformation applied to the sample. In oscillation, it’s a very small, controlled back-and-forth movement.

- Shear Modulus (G): This is a measure of the material's stiffness. It’s calculated as the stress divided by the strain.

- Law of Elasticity (Hooke's Law): For a perfect solid, stress is proportional to strain. Viscoelastic materials are more complex; their response depends on time and the rate of deformation.

Approaches to Measuring Viscoelastic Behavior

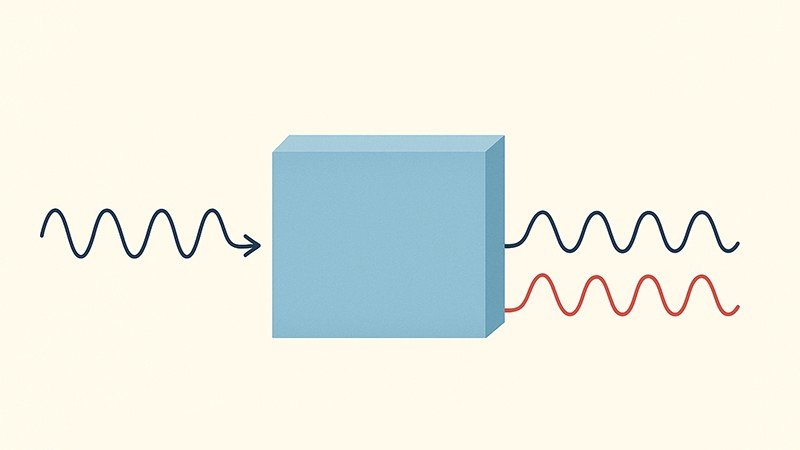

Oscillation tests are the standard way to measure viscoelastic properties. The rheometer applies a small, sinusoidal (wave-like) deformation to the sample. It then measures the material's response. From this, we get two key values:

- Storage Modulus (G'): This represents the elastic, or solid-like, part. It’s a measure of the energy stored and then recovered by the material during one cycle of oscillation. A high G' indicates a more structured, solid-like material.

- Loss Modulus (G''): This represents the viscous, or liquid-like, part. It’s a measure of the energy lost as heat when the material flows. A high G'' indicates a more fluid-like material.

The ratio of these, G''/G', is called Tan Delta. It quickly tells you if the material is predominantly solid-like (Tan Delta < 1) or liquid-like (Tan Delta > 1). This is vital for determining the stability and texture of products like yogurts, cosmetics, and adhesives.

Conclusion

Rheology is the key to understanding your material's flow. Rotational tests define viscosity, while oscillation tests measure viscoelasticity. This knowledge ensures you select the right instrument for quality control.