Need to estimate viscosity but don't have a viscometer? This lack can lead to guesswork and inconsistent product quality. Discover simple methods for a basic understanding.

Yes, you can roughly estimate a fluid's viscosity without a viscometer. Methods include simple observation, comparative tests, or basic DIY setups. These offer qualitative insights but lack professional precision.

As a manufacturer of rotational viscometers at Martests, I understand that precise measurement is key for quality. However, I also know that sometimes a quick, basic estimation is needed, especially for smaller labs or initial explorations. My insight, gained from many conversations with clients, is that "while professional viscometers offer precise results, many small labs or users still ask us about basic ways to estimate viscosity without instruments. Understanding these methods helps highlight the value of accurate tools." These simple techniques can be a starting point. But it's important to know their limits. Let's look at some of these non-instrumental ways to get a feel for viscosity.

What Simple Observational Methods Can Provide a Basic Indication of a Fluid's Viscosity?

No viscometer available for a quick fluid check? This can halt initial assessments or simple comparisons when you just need a rough idea. Use basic observation for an initial feel.

Simple visual cues like how a fluid pours from a container, drips from a rod, or coats a dipped surface can offer a very basic, qualitative indication of its relative viscosity.

Observational methods are the simplest way to get a general sense of a fluid's viscosity. They don't give numbers, but they can help you compare. For instance, you can observe how easily a liquid pours. Water pours very easily. Honey pours very slowly. This difference is due to viscosity. You can also dip an object, like a spoon or a rod, into the fluid and see how it drips off or coats the surface. A low-viscosity fluid like water will run off quickly and leave a thin film. A higher-viscosity fluid like paint will drip slowly and leave a thicker coating.

You can also swirl the fluid in a transparent container. Low-viscosity fluids will stop swirling quickly. Higher-viscosity fluids will continue to move for longer due to their internal resistance.

Common Observational Techniques:

- Pour Test: Observe the speed and nature of flow when pouring from one container to another. Is it fast and splashy, or slow and steady?

- Drip Test: Dip a rod or finger into the fluid and observe how it drips. Does it form quick, small drops or long, slow strands?

- Coating Test: Dip an object and see how much fluid clings to it and how evenly it coats.

- Swirl Test: Gently swirl the liquid in a jar and observe how quickly the motion stops.

These methods are very subjective. They depend a lot on the observer. But, they can be useful for a first quick check. For example, if I receive two samples of an oil that are supposed to be the same, a quick pour test might show me if one is obviously different. This wouldn't replace a proper test with our Martests viscometers for a client like Jacky in Italy, who needs precise quality. But it's a start.

Are There Comparative or Relative Tests You Can Perform to Judge Viscosity Differences Between Liquids?

Need to compare two liquids directly but lack a device? Just looking at them side-by-side might not be enough if the difference is subtle. Simple comparative tests offer clearer relative judgments.

Yes, you can perform comparative tests. For example, race liquids down an inclined plane or observe how quickly objects fall through them. These help judge relative viscosity differences more clearly.

When you have two or more liquids and want to know which is more viscous, comparative tests are better than just simple observation. These tests try to keep some conditions the same for all liquids being compared.

One common method is the incline plane test. You take a smooth, flat surface, like a sheet of glass or plastic. You prop it up at an angle. Then, you place equal-sized drops of the different liquids at the top of the incline at the same time. The liquid that flows to the bottom fastest is the least viscous. The one that flows slowest is the most viscous.

Another approach is a simplified falling object test. You need two identical transparent containers, each filled to the same level with a different liquid. Then, you drop identical small objects (like small beads or marbles) into each liquid at the same time from the same height. The object will fall faster through the less viscous liquid. It will fall slower through the more viscous liquid.

Comparing Liquids:

| Test Method | Observation for Lower Viscosity | Observation for Higher Viscosity | Notes |

|---|---|---|---|

| Incline Plane Race | Travels down faster | Travels down slower | Ensure equal drop size and starting point |

| Falling Object | Object falls quickly | Object falls slowly | Use identical objects and container sizes |

| Bubble Rise | Air bubble rises quickly | Air bubble rises slowly | Harder to do consistently without setup |

I recall a purchasing manager from a distributor in Southeast Asia asking about a quick way to show his customers the difference between two grades of cosmetic lotion. An incline plane test was a simple, visual way to demonstrate that one flowed much more slowly, indicating higher viscosity, before they decided to purchase viscometers for their own QC. These tests are still relative. They don't give absolute viscosity values in Pa·s or cP. But they are a step up from just looking.

Can Common Household Items or Basic DIY Setups Be Used for Rudimentary Viscosity Estimation?

No lab equipment on hand for even a basic viscosity guess? This can feel limiting when you need some idea of a fluid's thickness. Common household items can form simple estimation tools.

Yes, items like a funnel, a cup with a hole (a DIY efflux cup), or timing a marble falling through liquid in a jar can provide very rudimentary viscosity estimations.

If you're a bit resourceful, you can use common household items to create simple setups for estimating viscosity. These methods try to control variables a little more than pure observation.

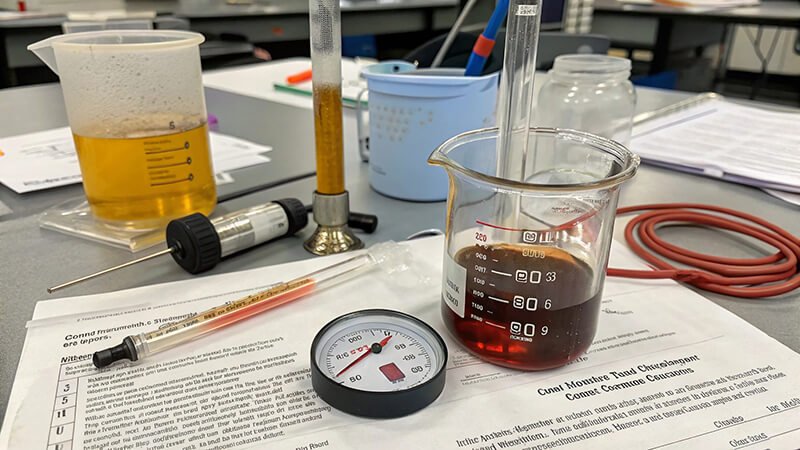

One popular DIY method is the efflux cup or funnel test. You can use a plastic cup and make a small, neat hole in the bottom. Or, you can use a standard kitchen funnel. The idea is to measure the time it takes for a specific volume of liquid to flow out through the hole or the funnel stem. You would fill the cup or funnel to a set mark. Then, you time how long it takes to empty. A less viscous liquid like water will empty quickly. A more viscous liquid like syrup will take much longer. You can compare the times for different liquids. This is a very basic version of what Zahn cups or Ford cups do in industry, but much less precise.

Another DIY method is the falling sphere method. You need a tall, clear container (like a glass jar or a plastic bottle with the top cut off), your test liquid, a small dense sphere (like a marble or a ball bearing), and a stopwatch. Fill the container with the liquid. Mark two points on the side of the container, one near the top (but below the surface) and one near the bottom. Drop the sphere into the liquid and time how long it takes to travel between the two marks. A faster time means lower viscosity. This is a very simplified version of the falling ball viscometer principle.

While these DIY methods are clever, their results are very approximate. Consistency in your setup (hole size, sphere size and weight, temperature) is key if you want to compare results even for yourself. We at Martests provide robust rotational viscometers for reliable data. But I appreciate the ingenuity of these simple tests for initial exploration.

What Are the Key Limitations and Inaccuracies When Attempting to Measure Viscosity Without a Dedicated Viscometer?

Relying on DIY or observational viscosity tests for important decisions? This approach can lead to inconsistent results, quality control problems, and misinformed choices. Understand the significant limitations.

Key limitations include a severe lack of precision and accuracy, poor repeatability, uncontrolled temperature effects, inability to characterize non-Newtonian fluids, and no standardized, comparable units of measurement.

While simple methods can give a general idea, it's crucial to understand their major drawbacks, especially if the viscosity information is important for product quality or performance.

Firstly, there's a lack of precision and accuracy. Observational methods are subjective. DIY tests are very sensitive to small changes in setup that are hard to control. The results are, at best, rough estimates.

Secondly, repeatability and reproducibility are poor. It's hard for one person to get the exact same result twice with a DIY setup. It's even harder for a different person to reproduce the result. This is a big problem for quality control.

Thirdly, temperature has a huge effect on viscosity. Most simple methods don't control or even measure temperature. A liquid will seem less viscous if it's warmer and more viscous if it's colder, and this can totally skew your observations. My client Jacky in Italy is very aware of this. He knows his product viscosity needs to be consistent across seasons, which means temperature-controlled measurements are vital.

Fourthly, these methods cannot properly characterize non-Newtonian fluids. Many fluids, like ketchup or paint, change their viscosity depending on how much force or shear is applied. Simple tests usually apply an unknown and inconsistent amount of shear. They cannot tell you how the fluid behaves under different conditions. Our Martests rotational viscometers are designed to test fluids at different shear rates for this very reason.

Finally, you get no standardized units. Results are in "seconds to flow" or "slower than honey." These are not comparable across different tests or labs. You cannot use these values for datasheets or to meet industry standards that require Pa·s or cP.

| Limitation | Impact of Using Non-Viscometer Methods |

|---|---|

| Precision & Accuracy | Results are only rough estimates, not exact values. |

| Repeatability | Difficult to get the same result even if you repeat the test. |

| Reproducibility | Very hard for someone else to get the same result you did. |

| Temperature Effects | Uncontrolled temperature changes make results unreliable. |

| Non-Newtonian Behavior | Cannot tell how viscosity changes with shear (e.g., stirring, pumping). |

| Standardized Units | No values like Pascal-seconds or centipoise for comparison. |

These limitations are why businesses that rely on viscosity for product quality or process control invest in proper viscometers. The initial saving from not buying an instrument can be quickly lost through inconsistent products or material failures.

Conclusion

Basic observational and DIY methods offer rough viscosity ideas. But for accurate, repeatable, and meaningful measurements, a dedicated viscometer is truly essential for reliable results and quality assurance.