Is your product quality inconsistent? Temperature fluctuations might be the culprit affecting your material's viscosity. Even slight temperature changes can dramatically impact flow behavior, undermining your quality control efforts.

When temperature increases, liquid viscosity typically decreases as molecules gain energy and move more freely. Conversely, when temperature drops, liquid viscosity increases. This relationship is fundamental to quality control in manufacturing processes.

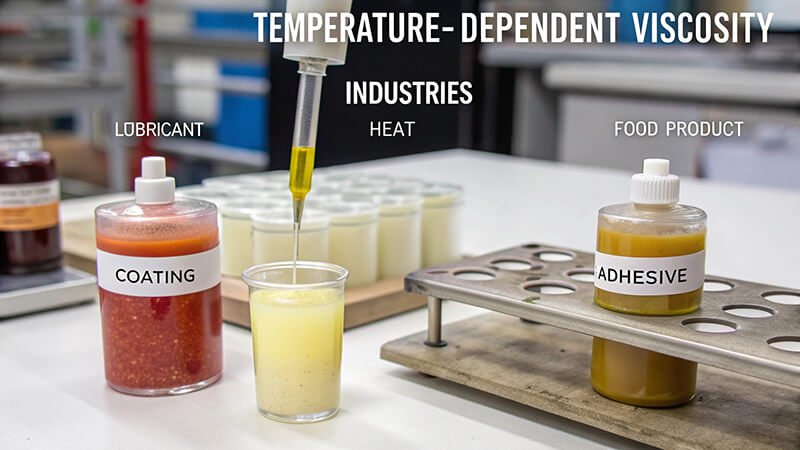

In my years providing rotational viscometers to different industries, I've realized that the relationship between viscosity and temperature isn't just about changing physical parameters. It's a critical factor in product quality control. In lubricants, coatings, food products, or chemicals, even small temperature fluctuations of just 1-2°C can cause significant viscosity differences, affecting the final product's performance stability. That's why precisely monitoring and controlling viscosity changes with temperature is a non-negotiable technical aspect of many manufacturing processes.

What Is the Relationship Between Temperature and Viscosity?

Have you noticed how honey flows easily when warm but becomes thick and sluggish when cold? This everyday observation demonstrates the profound effect temperature has on a fluid's behavior.

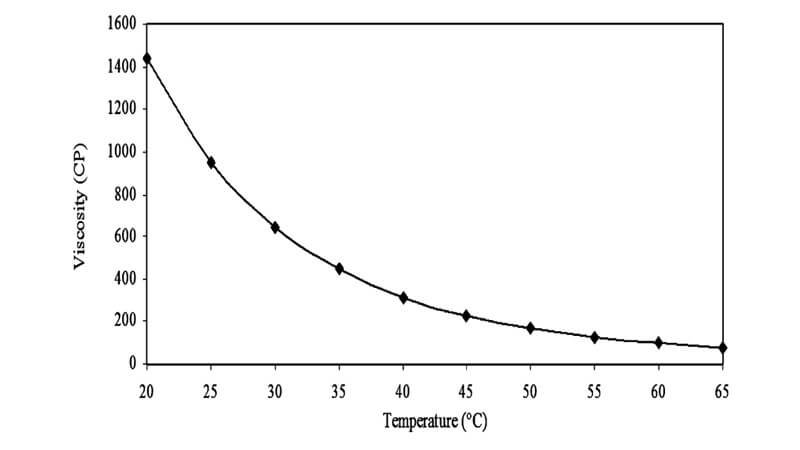

Temperature and viscosity generally have an inverse relationship in liquids: as temperature rises, viscosity decreases exponentially. In contrast, gases exhibit the opposite behavior, with viscosity increasing as temperature rises due to increased molecular collision rates.

When I explain viscosity to customers like Jacky from Italy, who distributes our viscometers, I describe it as a fluid's resistance to flow. For liquids, this resistance comes from intermolecular attractions holding molecules together. As temperature increases, molecules gain more kinetic energy, moving faster and spending less time near neighboring molecules. This reduces the effectiveness of intermolecular forces, allowing molecules to slide past each other more easily.

The Arrhenius equation often helps quantify this relationship:

η = A × e^(Ea/RT)

Where:

- η is viscosity

- A is a material-specific constant

- Ea is the activation energy for flow

- R is the gas constant

- T is temperature in Kelvin

This exponential relationship explains why viscosity changes aren't uniform - a 10°C temperature increase might reduce viscosity dramatically at lower temperatures but have less impact at higher temperatures. Understanding this non-linear behavior is crucial for any process where precise viscosity control matters.

Temperature Effects on Different Fluid Types:

| Fluid Type | Temperature Increase Effect | Primary Mechanism | Example |

|---|---|---|---|

| Newtonian Liquids | Viscosity decreases | Reduced intermolecular forces | Water, mineral oils |

| Non-Newtonian Liquids | Complex changes in flow behavior | Changes in molecular structure and interactions | Polymer solutions, food products |

| Gases | Viscosity increases | Increased molecular collisions | Air, natural gas |

I've found that helping customers understand these fundamental relationships improves their ability to troubleshoot process issues and maintain consistent product quality.

Why Does Viscosity Decrease When Temperature Increases?

Do you find your production batches inconsistent between summer and winter? The molecular changes happening as temperatures fluctuate are likely affecting your product's flow properties in ways that impact quality.

When temperature rises, liquid molecules gain kinetic energy and move more vigorously. This increased movement overcomes the intermolecular attractive forces, reducing internal friction. The molecules slide past each other more easily, resulting in lower viscosity.

I often use a simple analogy when training customers on our viscometers: imagine a crowded room where people represent molecules. At low temperatures (a calm environment), people move slowly and orderly, creating resistance to movement – high viscosity. Turn up the temperature (like playing energetic music), and people move faster and more randomly, creating less resistance to movement – lower viscosity.

The reduction in viscosity follows predictable patterns for many materials, often described by mathematical models like the Arrhenius equation or the Williams-Landel-Ferry (WLF) equation for polymers. These models help predict how much viscosity will change with temperature, which is essential for quality control.

Different materials show varying sensitivity to temperature changes:

- Water's viscosity decreases by about 20% for every 10°C rise

- Honey might decrease by 500% with the same temperature increase

- Motor oils are formulated specifically to minimize viscosity changes with temperature

This temperature sensitivity is why we at Martests emphasize temperature control systems in our rotational viscometers. When discussing requirements with customers, I always highlight that temperature consistency can be more important than absolute accuracy for ensuring repeatable measurements and consistent product quality.

How Can You Measure Viscosity at Different Temperatures?

Are you getting inconsistent viscosity readings despite using the same sample and settings? Without proper temperature control, your measurements are essentially meaningless for quality assurance purposes.

To accurately measure viscosity at different temperatures, use a rotational viscometer with integrated temperature control features like a water circulation jacket, Peltier system, or temperature-controlled chamber. Allow sufficient equilibration time before taking readings.

When I consult with customers about their viscosity measurement needs, I stress that temperature control isn't an optional luxury—it's a fundamental requirement for meaningful data. At Martests, we've noticed more customers focusing on temperature control precision, instrument stability, and data traceability rather than just measurement range when selecting viscometers.

For accurate temperature-controlled viscosity measurements, follow these essential steps:

- Select appropriate temperature control hardware: Water baths offer excellent stability but require external equipment. Peltier systems provide faster temperature changes and are more compact. Environmental chambers work well for measurements across wide temperature ranges.

- Ensure proper sample temperature equilibration: Place your sample in the temperature control system and allow sufficient time for it to reach uniform temperature throughout. For most liquids, I recommend at least 10-15 minutes, but high-viscosity or thermally insulative materials may require longer.

- Verify with temperature probes: Use a calibrated temperature probe directly in your sample to confirm it has reached the target temperature before measuring.

- Account for temperature gradients: Be aware that temperature might not be uniform throughout your sample, especially in larger volumes. Use appropriate container sizes and spindle geometries to minimize this effect.

- Document all conditions: Record not just the viscosity value but also the exact temperature, spindle type, rotation speed, and sample preparation method to ensure repeatability.

For comprehensive viscosity profiling, our advanced viscometers can perform automated temperature ramps, measuring viscosity continuously as temperature changes. This provides complete viscosity-temperature curves that reveal critical information about material behavior across your process conditions.

What Are the Industrial Applications of Temperature-Dependent Viscosity?

Have you ever wondered why some products perform differently depending on the season or climate? Understanding how temperature affects viscosity is critical for everything from food palatability to automotive reliability.

Temperature-dependent viscosity knowledge is essential in numerous industries: lubricant formulation ensures engine protection across temperature extremes, food processing maintains consistent texture and mouthfeel, coatings achieve proper application and appearance, and adhesives maintain bonding strength.

My work with rotational viscometers across different sectors has shown me countless applications where understanding and controlling temperature-viscosity relationships are mission-critical:

In the lubricant industry, multigrade oils must maintain adequate viscosity at both cold startup temperatures and hot operating conditions. Viscosity index improvers are added to reduce temperature sensitivity. I've worked with formulators who test their oils at temperatures ranging from -40°C to over 100°C to ensure proper performance.

For food manufacturers, temperature-dependent viscosity affects both processing efficiency and final product quality. Chocolate conching and tempering requires precise viscosity control through temperature adjustment. One chocolate manufacturer I assisted discovered that maintaining temperature within ±1.5°C throughout their process resolved inconsistent molding issues they'd struggled with for months.

Paint and coating companies face significant challenges with temperature effects. A major paint distributor who uses our viscometers found that their water-based formulations behaved very differently between winter and summer factory conditions. Implementing temperature-controlled viscosity testing allowed them to adjust formulations seasonally for consistent application properties.

In pharmaceutical production, temperature control ensures consistent drug delivery from suspensions and adequate dosing from syrups. The viscosity of these products must remain within specification across storage and usage conditions.

Chemical processing operations depend on predictable flow behaviors for proper mixing, pumping efficiency, and reaction kinetics. One chemical manufacturer improved their batch consistency by 30% after implementing proper temperature-controlled viscosity monitoring using our equipment.

By understanding these temperature-viscosity relationships, manufacturers can design more robust processes, formulate more stable products, and ultimately deliver more consistent quality to their customers.

How to Control and Maintain Viscosity at Various Temperatures?

Are temperature fluctuations causing headaches in your production process? Inconsistent viscosity leads to quality problems, but with the right strategies, you can maintain optimal flow properties regardless of ambient conditions.

To control viscosity across temperatures, use jacketed vessels with precise heating/cooling systems, modify formulations with viscosity index improvers or thixotropic additives, and implement continuous monitoring with rotational viscometers for real-time adjustments.

From my experience helping clients implement viscosity control systems, successful temperature management requires a multi-faceted approach:

Direct Temperature Control Systems

The most straightforward method is maintaining optimal processing temperatures:

- Jacketed vessels and pipelines: Circulate temperature-controlled fluids through the jacket to maintain consistent product temperature. I've seen double-jacketed systems provide even better temperature uniformity for sensitive processes.

- Heat exchangers: For continuous processes, plate or tubular heat exchangers can quickly adjust product temperature before critical processing steps.

- Insulation: Properly insulating vessels and transfer lines prevents unwanted temperature fluctuations. This simple addition has solved many consistency problems for our customers.

- Localized heating/cooling: For specific process points like nozzles or fill heads where viscosity is especially critical.

Formulation Adjustments

When direct temperature control isn't sufficient:

- Viscosity index improvers: These polymeric additives help maintain more consistent viscosity across temperature ranges. Common in lubricants but also used in cosmetics and certain industrial fluids.

- Thixotropic additives: Create shear-thinning behavior that can compensate for temperature effects during application or processing.

- Multiple-component systems: Blending components with different temperature sensitivities can create formulations with more stable overall viscosity.

Measurement and Feedback Systems

This is where rotational viscometers become essential:

- Inline viscometers: Continuously monitor process viscosity and send feedback to control systems.

- Routine quality checks: Implementing scheduled viscosity measurements at process temperature helps identify drift before it causes problems.

- Temperature-viscosity mapping: Creating detailed profiles of your material's behavior across your operating temperature range provides a baseline for troubleshooting.

One food processing client implemented an integrated approach using our rotational viscometers with temperature control as both QC instruments and development tools. They created temperature-viscosity profiles for each product, installed jacketed lines with precision temperature control, and adjusted formulations with temperature-stable thickeners. The result was consistent product texture regardless of seasonal temperature variations.

Conclusion

Understanding how viscosity changes with temperature is essential for product quality and process efficiency. With proper measurement tools, temperature control systems, and formulation strategies, you can maintain consistent viscosity despite temperature variations.