Struggling with inconsistent fluid flow? This can cause big problems in many processes. Understanding viscosity's link to flow rate is key to fixing this.

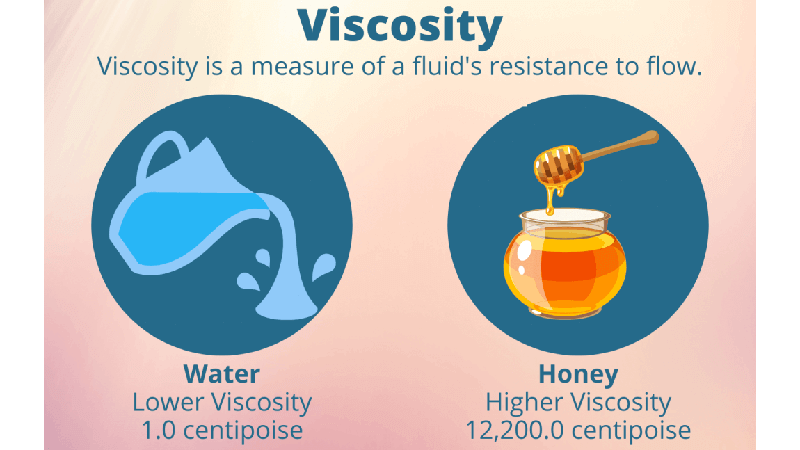

Viscosity is a fluid's resistance to flow. So, higher viscosity means the fluid is "thicker" and flows more slowly. Lower viscosity means it's "thinner" and flows faster, given the same conditions.

Many people wonder about this direct link. It seems simple, but the details are important. As someone who provides viscometers through Martests, I know how vital this understanding is. My clients, like Jacky in Italy who distributes lab instruments, often need to explain this to their own customers. So, let's explore how viscosity and flow rate are connected.

What is the concept of viscosity?

Does the term "viscosity" seem a bit technical or confusing? If you don't grasp it, you might struggle with fluid handling. Let's break it down simply.

Viscosity is the measure of a fluid's internal friction when its layers move against each other. Think of it as "thickness." Temperature greatly affects it; liquids usually get less viscous when hotter.

Viscosity is a basic property of fluids – that means liquids and gases. It tells us how much a fluid resists flowing. Imagine stirring honey versus stirring water. Honey resists more. That resistance is viscosity.

At Martests, we explain viscosity as the internal friction between moving layers of a fluid. When a fluid flows, its different parts move at different speeds. Viscosity measures how much these parts "drag" on each other.

Several things change a fluid's viscosity:

- Temperature: This is a big one. For most liquids, when you increase the temperature, the viscosity goes down. The liquid becomes thinner and flows more easily. Think of warming up syrup. For gases, it's usually the other way around – they get more viscous when heated.

- Pressure: Pressure can also change viscosity, but usually, its effect is much smaller than temperature's, especially for liquids.

- Type of Fluid: Different fluids have different molecular structures. The forces between their molecules determine their natural viscosity. Water flows easily; molasses flows slowly due to these internal forces.

We measure viscosity in units like Pascal-seconds (Pa·s) or Poise (P). I remember a client who was having trouble with inconsistent product batches. It turned out that small temperature changes in their factory were altering the viscosity of a key ingredient, affecting the final product's flow. Once they started monitoring viscosity with our instruments, they could control it better.

What exactly is flow rate?

Is "flow rate" just about how fast something pours? Not quite. Getting this wrong can lead to inefficient systems or incorrect dosing. Let's define it.

Flow rate is the amount (volume or mass) of fluid that passes through a specific point or cross-section in a certain amount of time. It's driven by pressure and affected by pipe size and fluid properties.

Flow rate tells us how much fluid moves through a system over a period. You can think of it as the speed of the fluid, but it's more precise. It's usually about the volume of fluid (like liters per minute) or the mass of fluid (like kilograms per second) passing a point.

Several factors determine the flow rate:

- Pressure Difference: This is the main driving force. Fluid flows from an area of higher pressure to an area of lower pressure. The bigger the pressure difference, the faster the flow, generally. Think of water flowing from a full tank – the pressure at the bottom is higher.

- Pipe or Channel Size and Shape: The diameter and length of a pipe significantly affect flow. A wider pipe allows more fluid to pass through than a narrow one, assuming other factors are equal. The shape of the channel also matters.

- Fluid's Own Properties: Here's where viscosity comes in, which we'll discuss more. The fluid's density also plays a role.

- Gravity: For fluids flowing downwards, gravity helps. For fluids flowing upwards, gravity works against the flow.

My friend Jacky in Italy often advises his clients on setting up systems for paints or chemicals. He always stresses considering the desired flow rate, then working backward to choose the right pump (for pressure) and pipe diameter, always keeping the fluid's viscosity in mind. It’s all connected.

How does viscosity directly impact flow rate mechanisms?

Why does a thick liquid flow slower? If you don't understand the "how," you can't optimize flow. It’s about internal forces and energy.

Higher viscosity means stronger internal friction within the fluid. This friction resists the movement of fluid layers past each other, consumes energy, and thus reduces the overall flow rate.

The way viscosity affects flow rate is all about what's happening inside the fluid at a molecular level. It’s not just a simple "thicker means slower" statement; there are clear physical reasons.

First, let's talk about internal friction. Viscosity is a measure of this. Fluids with high viscosity, like honey or heavy oils, have strong forces between their molecules. When these fluids try to flow, these strong intermolecular forces create a lot of internal "rubbing" or friction. This friction acts as a brake, resisting the movement of different layers of the fluid past one another. So, more internal friction means it's harder for the fluid to get going and keep moving, which naturally results in a slower flow rate for a given push.

Second, consider energy dissipation. To make a fluid flow, you need to apply energy, often from a pump creating a pressure difference. As the fluid moves, some of this energy is used up just to overcome the viscous friction we just talked about. This "lost" energy is usually converted into heat. The higher the viscosity, the more energy is lost to this internal friction. This means less of the initial energy is available to actually move the bulk of the fluid forward. So, with more energy being wasted as heat, the resulting flow rate is lower.

Third, there's the relationship between shear stress and shear rate. Viscosity is technically defined as the ratio of shear stress (the force per unit area causing the fluid to deform or flow) to shear rate (how quickly the fluid deforms or flows). If you apply a certain amount of force (shear stress) to try and move a fluid, a high-viscosity fluid will deform or flow much more slowly (low shear rate) compared to a low-viscosity fluid. This directly translates to a slower overall flow rate.

What is Poiseuille's Law and how does it quantify this relationship?

Need a precise way to link viscosity and flow? Guessing can be costly. Poiseuille's Law gives us a mathematical formula for specific situations.

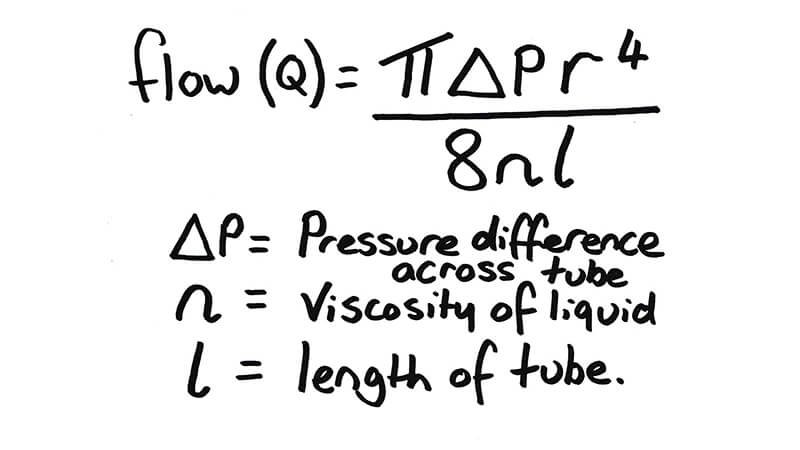

Poiseuille's Law shows that for smooth, laminar flow in a straight circular pipe, the flow rate (Q) is inversely proportional to the fluid's viscosity (η). So, if viscosity doubles, flow rate halves.

When we want to get more exact about how viscosity affects flow rate, especially in pipes, we often turn to a principle called Poiseuille's Law. This law is very useful, but it's important to remember it applies under specific conditions: the flow must be laminar (smooth, not turbulent), the fluid must be incompressible (like most liquids), it should be a Newtonian fluid (viscosity doesn't change with flow speed), and the pipe must be straight and circular.

The formula for Poiseuille's Law looks like this:

Q = (ΔP π r⁴) / (8 η L)

Let's break down what these symbols mean:

- Q is the volumetric flow rate (how much fluid flows per unit of time).

- ΔP is the pressure difference between the two ends of the pipe (the driving force).

- r is the radius of the pipe.

- η (the Greek letter eta) is the dynamic viscosity of the fluid.

- L is the length of the pipe.

- π and 8 are constants.

Looking at this formula, you can clearly see the relationship. Viscosity (η) is in the denominator. This means that if everything else stays the same, and you increase the viscosity (η), the flow rate (Q) will decrease. They are inversely proportional. If viscosity doubles, flow rate is cut in half.

The law also highlights how much the pipe's radius (r) matters – it's raised to the fourth power! This means a small change in pipe diameter has a huge effect on flow rate. However, for any given pipe, viscosity is a direct factor working against that flow. At Martests, when we supply viscometers, we often remind our B2B partners that their customers designing fluid systems, like pipelines for oil or channels for food products, can use principles like Poiseuille's Law to predict performance and troubleshoot issues related to flow and viscosity.

What about non-Newtonian fluids and their flow?

Do all fluids follow the simple "viscosity vs. flow" rule? No, some are tricky. Non-Newtonian fluids change their viscosity with flow conditions, complicating things.

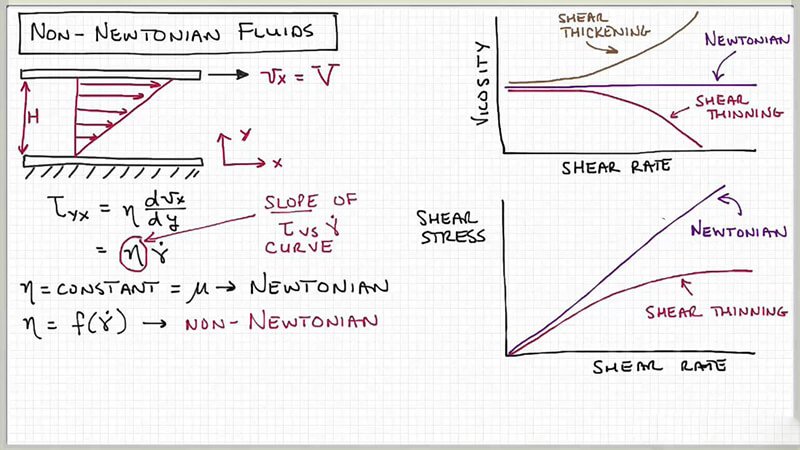

Non-Newtonian fluids have viscosity that isn't constant; it changes with shear rate (flow speed). Shear-thinning ones (like ketchup) can flow faster under stress, while shear-thickening ones (like cornstarch slurry) resist more.

So far, we've mostly talked about how viscosity affects flow rate in a straightforward way, assuming the viscosity itself is a constant property for a given fluid at a certain temperature. This is true for what we call Newtonian fluids, like water or simple oils. However, many fluids in industry and nature are non-Newtonian. This means their viscosity actually changes depending on how fast they are being forced to flow (the shear rate).

This makes their relationship with flow rate more complex:

- Shear-thinning fluids: These fluids become less viscous (thinner) when you apply stress or try to make them flow faster. A classic example is ketchup. It’s thick in the bottle, but if you shake it (apply shear) or squeeze it hard, it thins out and flows more easily. For these fluids, increasing the pressure to get a higher flow rate can also decrease their viscosity, which might lead to an even greater increase in flow rate than you'd expect for a Newtonian fluid. Other examples include many paints, cosmetic lotions, and some polymer solutions.

- Shear-thickening fluids: These do the opposite. They become more viscous (thicker) when you apply stress or try to make them flow faster. A common example is a mixture of cornstarch and water. If you try to stir it quickly or punch it, it becomes almost solid. In a pipe, trying to force a shear-thickening fluid to flow faster could dramatically increase its viscosity, potentially leading to a much slower flow rate or even a blockage.

- Thixotropic and Rheopectic fluids: Some non-Newtonian fluids also show time-dependent viscosity. Thixotropic fluids become less viscous over time when subjected to constant shear (like yogurt). Rheopectic fluids become more viscous over time under constant shear (less common).

Understanding these behaviors is critical. For instance, if you're pumping a shear-thinning sauce, you need to know how its viscosity will drop in the pump and pipes. Our more advanced Martests viscometers can help characterize these non-Newtonian behaviors, providing valuable data for industries that handle such complex fluids.

Why is understanding viscosity and flow rate so important in practice?

Is this just academic knowledge? Definitely not. Getting viscosity and flow wrong can stop production lines or create unsafe conditions. It’s crucial for real-world success.

Understanding the viscosity-flow rate link is vital for engineering (pipe/pump design), medicine (blood flow), industry (lubricants, paints), and even daily life (honey vs. water). It ensures efficiency, safety, and product quality.

The relationship between viscosity and flow rate isn't just an interesting scientific concept; it has huge practical importance across many fields. As a supplier of viscometers through Martests, I see firsthand how critical this understanding is for my B2B customers and their clients.

In engineering design, it's fundamental. When designing pipeline systems for oil and gas, chemical plants, or water distribution, engineers must calculate the expected flow rates. They need to choose the right pipe diameters and pump capacities, and viscosity is a key input for these calculations. If viscosity is underestimated, the system might not deliver the required flow. If overestimated, the system might be over-designed and too costly.

In biomedical fields, think about blood circulation. Blood is a fluid, and its viscosity is a crucial factor for cardiovascular health. Changes in blood viscosity can affect blood pressure and the workload on the heart. Understanding flow is also important for designing drug delivery systems or medical devices that interact with body fluids.

For industrial production, many processes involve moving or processing fluids. Think about selecting the right lubricants for machinery; the oil must flow correctly at operating temperatures. In manufacturing paints, inks, coatings, and cosmetics, viscosity control is essential for application properties and product consistency. For example, paint needs to flow well from the brush or sprayer but not drip too much once applied. In food processing, the viscosity of products like sauces, dairy, or beverages affects how they are pumped, mixed, and packaged.

Even in daily life, we see this relationship. Why does honey pour so much slower than water? Viscosity. Why are there different grades of motor oil for different engines and climates? Again, it's about ensuring the oil has the right viscosity to flow properly and protect the engine parts under various conditions.

At Martests, our goal is to provide top-quality viscometers and related accessories to help businesses accurately measure and control viscosity. This empowers them to optimize their processes, ensure product quality, and improve efficiency, whether they are in Europe, Southeast Asia, or the Middle East.

Conclusion

Simply put, higher viscosity means slower flow. This basic link, governed by internal friction, is vital for designing efficient systems and ensuring product quality across many industries.