Confused by the wide range of viscometer prices? High costs can strain your budget, making it hard to choose the right instrument for your needs. Let's explore this.

Rotational viscometer prices vary widely, from basic models around $400 to advanced systems exceeding $10,000. At Martests, our own range reflects this, catering to diverse needs and budgets.

Understanding what drives these price differences is key for buyers like Jacky, who owns a distribution company in Italy. He needs to offer his customers good value but also instruments that deliver reliable performance. As a factory, Martests manufactures rotational viscometers that span this spectrum, from economical $400 units to sophisticated $10,000 instruments. The final price tag is a sum of many parts, each contributing to the instrument's capability and performance. Let's delve into the factors that determine the cost.

How Does Measurement Accuracy Influence Viscometer Price?

Getting unreliable viscosity readings? Inaccurate instruments can lead to inconsistent product quality and wasted resources, frustrating your quality control efforts. This matters.

Higher accuracy and precision in rotational viscometers, achieved through superior components like motors, sensors, and meticulous calibration, significantly increase their price. This investment ensures more dependable results.

Accuracy is paramount in viscosity measurement, and it's a major cost driver. A viscometer's ability to consistently deliver correct readings depends on several internal factors. For instance, the motor that drives the spindle must maintain a very precise and stable speed across all settings. Any fluctuation here directly impacts the shear rate and thus the viscosity reading. High-precision stepper motors or servo motors are more expensive than simpler motor types.

Then there's the torque sensor. This component measures the resistance the fluid exerts on the rotating spindle. More sensitive and accurate torque sensors, capable of detecting subtle differences in resistance, especially at very low or very high viscosity ranges, add to the cost. The precision of the spindles themselves, their geometry, and finish also play a role. Finally, the calibration process is critical. Instruments that undergo more rigorous, multi-point calibration with certified reference materials will naturally be priced higher. For our customers in Europe and Southeast Asia who demand top quality, these elements are non-negotiable, even if it means a higher initial investment. We ensure our Martests viscometers, whether basic or advanced, meet their stated accuracy specifications.

| Feature Component | Impact on Accuracy | Cost Implication |

|---|---|---|

| Motor Type | Speed stability and precision | Higher |

| Torque Sensor | Sensitivity and range | Higher |

| Spindle Manufacturing | Dimensional accuracy, surface finish | Moderate |

| Calibration Process | Traceability, number of points | Moderate |

What Impact Does Temperature Control Have on Rotational Viscometer Cost?

Are your viscosity results inconsistent across different days? Temperature fluctuations can drastically alter fluid viscosity, making your measurements unreliable if not properly managed.

Integrated temperature control systems, like Peltier elements or connections for external circulators, significantly add to a rotational viscometer's cost but are crucial for accurate, repeatable measurements.

Temperature is one of the most critical factors affecting viscosity. For most fluids, viscosity decreases as temperature increases, and vice-versa. Even a small change of one or two degrees Celsius can lead to a significant change in viscosity, especially for sensitive materials. Therefore, precise temperature control during measurement is not just a luxury; it's often a necessity for obtaining meaningful and comparable results.

Basic viscometers might not have any temperature control, relying on the ambient laboratory temperature or requiring the user to employ an external water bath. More advanced, and thus more expensive, models incorporate temperature control directly. Some use Peltier elements, which can heat or cool the sample holder electronically, offering rapid temperature changes and precise stability. Others are designed with jackets for circulating fluid from an external thermostatic bath. These systems require additional components: temperature sensors (like Pt100), controllers, and sometimes sophisticated heat exchange mechanisms. All these add to the complexity and manufacturing cost. For distributors like Jacky, whose customers might be testing anything from food products to industrial oils, offering viscometers with reliable temperature control is a key selling point. We provide options in our Martests range, understanding its importance for many applications.

| Temperature Control Method | Precision Level | Cost Adder | Common Use Cases |

|---|---|---|---|

| None (Ambient) | Low | None | Basic QC, less sensitive fluids |

| Water Bath Connection | Moderate to High | Low to Moderate | General lab use, stable temperature required |

| Integrated Peltier System | High | High | R&D, pharmaceuticals, temperature ramping studies |

| Circulating Fluid Jacket | High | Moderate | Larger sample volumes, specific temperature needs |

How Do Advanced Features and Software Affect Viscometer Pricing?

Limited by basic readouts and manual data recording? This can be slow and error-prone, especially for complex analyses or high-throughput labs needing efficiency.

Advanced features like programmable test methods, data logging, computer interface software for rheological analysis, and intuitive touchscreens significantly increase a rotational viscometer's price but enhance usability and analytical power.

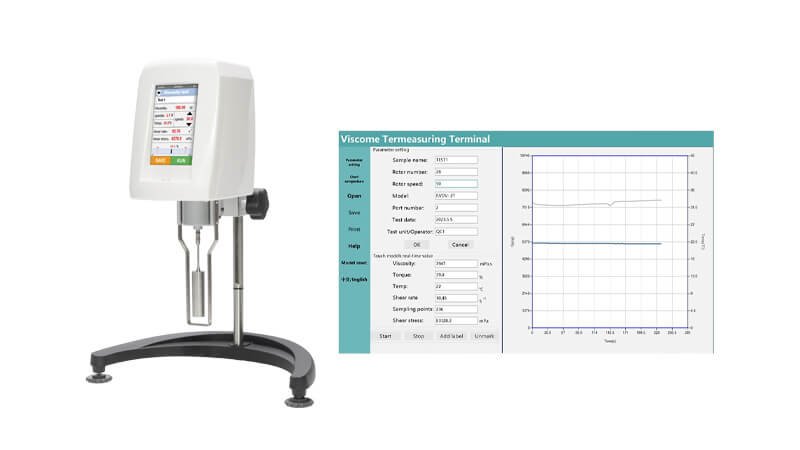

Beyond the core function of measuring viscosity, many modern rotational viscometers come packed with features that enhance their utility, and these contribute to the price. A basic viscometer might only display the current viscosity and speed. However, more sophisticated models often include built-in microprocessors and memory. This allows for features like programmable test sequences – for example, automatically running a test at multiple speeds or over a set time period. Data logging directly onto the instrument or a USB drive saves time and reduces transcription errors.

Computer connectivity via USB or RS232 ports, along with dedicated software, is another significant value-adder that impacts cost. This software can range from simple data transfer to comprehensive rheological analysis packages that allow users to model flow behavior, determine yield stress, and perform other advanced calculations. User interfaces also vary; a simple button-based system is cheaper to implement than a full-color touchscreen display that offers more intuitive navigation and graphical data representation. For our clients in industries like pharmaceuticals or research, who need detailed data analysis and good laboratory practice (GLP) compliance, these features are often essential. Martests provides models with varying levels of such features to meet different analytical and budgetary needs. Customizing the logo on these advanced units is also a service we proudly offer to our B2B partners.

| Feature | Benefit | Cost Impact | Target User |

|---|---|---|---|

| Programmable Tests | Automation, consistency, complex profiles | Moderate | R&D, advanced QC |

| Data Logging | Record keeping, traceability | Low-Moderate | Most users requiring documentation |

| PC Software | Advanced analysis, reporting, control | Moderate-High | Researchers, labs with high analytical needs |

| Touchscreen Interface | Ease of use, better data visualization | Moderate | Users valuing convenience and modern interface |

| Multiple User Accounts | Security, method protection | Low | Labs with multiple operators |

Why Do Different Viscometer Types (e.g., Cone-Plate) Vary in Cost?

Is a standard spindle viscometer not meeting your specific sample needs? Small sample volumes or the need for absolute shear rates require specialized geometries.

Specialized rotational viscometers like cone-and-plate or coaxial cylinder systems are more expensive due to their precision mechanics, ability to handle small samples, and define absolute shear rates, unlike basic spindle types.

Not all rotational viscometers are built the same way, and the measurement geometry significantly impacts cost. The most common and generally most affordable type is the rotating spindle viscometer. These use various spindles (disc, cylindrical) immersed in a relatively large sample volume within a beaker or container.

However, for certain applications, more specialized geometries are needed. Cone-and-plate viscometers, for example, use a shallow-angle cone rotating close to a flat plate. This setup requires very precise manufacturing for the cone and plate, and an extremely accurate mechanism for setting the tiny gap between them (often just microns). The advantage is that it creates a constant, well-defined shear rate across the sample, which is crucial for accurate rheological studies, especially of non-Newtonian fluids. It also allows for measurements with very small sample volumes, sometimes less than 1 mL. Coaxial cylinder viscometers (like Couette or Searle types) involve one cylinder rotating inside another, with the sample in the annular gap. These also offer well-defined shear conditions and are often used for absolute viscosity measurements. The precision engineering and more complex mechanics of these systems naturally lead to higher prices compared to standard spindle viscometers. Martests produces these different types, understanding that our distributors need to cater to diverse customer requirements, from basic quality control to advanced research.

| Viscometer Type | Key Characteristic | Typical Price Range | Sample Volume | Shear Rate Definition |

|---|---|---|---|---|

| Rotating Spindle | Versatile, larger sample volume | Lower to Mid | Larger | Variable, less defined |

| Cone and Plate | Small sample, defined shear rate, precise gap | Mid to Higher | Very Small | Well-defined |

| Coaxial Cylinder | Absolute viscosity, well-defined shear field | Mid to Higher | Moderate | Well-defined |

Does Compliance with Industry Standards Add to Viscometer Expenses?

Need your viscosity data to meet specific industry regulations or test methods? Basic instruments might not provide the necessary traceability or conformity.

Viscometers designed and verified to comply with specific industry standards (e.g., ASTM, ISO, Pharmacopoeia) often cost more due to required design features, rigorous testing, and documentation for traceability.

In many industries, viscosity measurements must adhere to specific standards, such as those published by ASTM International, ISO (International Organization for Standardization), or pharmacopoeias (e.g., USP, EP). Compliance with these standards ensures that results are consistent and comparable across different laboratories and instruments. Achieving this compliance adds to the cost of a viscometer.

For example, a standard might specify a particular spindle geometry, a defined shear rate range, or a specific procedure for temperature control and calibration. Manufacturers like us at Martests must ensure our instruments are designed and built to meet these requirements. This can involve using specific materials, adhering to tighter manufacturing tolerances, and implementing particular features. Furthermore, verifying compliance often involves additional testing and documentation, which contributes to the overhead. For instance, providing calibration certificates traceable to national or international standards is a cost factor. For purchasing managers at large instrument distributors, like those we serve in Europe and the Middle East, offering viscometers that can demonstrably meet key industry standards is crucial for their customers in regulated sectors such as pharmaceuticals, food, or petroleum. While it increases the price, it provides an assurance of data reliability and acceptability.

| Standard Example | Industry Focus | Key Viscometer Implications | Cost Impact |

|---|---|---|---|

| ASTM D2196 | Non-Newtonian Liquids | Specific spindle types, rotational speeds | Moderate |

| ISO 2555 | Resins, Liquids | Standard spindle geometries, test conditions | Moderate |

| USP <912> | Pharmaceutical | Rotational methods, calibration, system suitability | Moderate |

| ASTM D445/ISO 3104 | Petroleum Products | (Primarily for kinematic, but context for quality) | N/A direct |

Conclusion

Rotational viscometer costs range from $400 to $10,000, driven by accuracy, temperature control, features, type, and compliance. Martests offers diverse options to match specific needs and budgets.