Frustrated by inconsistent viscometer readings? These errors can ruin experiments and product quality. Learn key steps for reliable, precise measurements every time.

To get consistent and accurate results with a rotational viscometer, control temperature precisely, choose the correct spindle and speed, ensure proper sample preparation, and regularly calibrate your instrument. These steps minimize variability.

Getting reliable viscosity data is crucial for many industries. I've seen firsthand in our factory how small oversights can lead to big problems. So, let's look closer at what really makes a difference. We'll explore the critical factors one by one to help you master your viscometer.

How Does Temperature Variation Affect Viscosity Measurements and How Can I Control It?

Wildly fluctuating viscosity readings messing up your data? Uncontrolled temperature changes are often the hidden culprit. Understand temperature's impact and implement precise control for stable results.

Temperature variation significantly alters fluid viscosity; higher temperatures usually decrease viscosity. Control it using a circulating water bath1 or a viscometer with integrated temperature control to ensure consistent and accurate readings.

Temperature is probably the biggest single factor affecting viscosity. Most liquids become less viscous as temperature rises. Some change dramatically with just a one-degree shift. I remember a customer, let's call him Jacky from Italy, who was getting inconsistent results for a polymer solution he planned to resell. We discovered his lab temperature fluctuated quite a bit throughout the day. This was the main source of his issues. As a B2B wholesale supplier, we at Martests always emphasize this to our distributors. Precision is about the whole process, not just the equipment.

Why Temperature Matters So Much

- Molecular Motion: Higher temperature means more kinetic energy. Molecules in the liquid move faster. They can overcome the forces that attract them to each other more easily. This reduces the liquid's resistance to flow, which is what we call viscosity.

- Material Specifics: Some materials are far more sensitive to temperature changes than others. For example, oils, syrups, and many polymer solutions show large viscosity changes with even small temperature shifts. For these, precise temperature control is absolutely essential.

How to Minimize Temperature Effects

We need to keep the sample at a constant, known temperature during the test. Here are some common ways:

| Control Method | Description | My Recommendation |

|---|---|---|

| Circulating Water Bath | This device circulates temperature-controlled water around the sample container. It's very effective for precise control. | This is essential for achieving high accuracy, especially with temperature-sensitive samples. We often suggest these to clients purchasing our rotational viscometers. |

| Peltier Temperature Unit | This is an electronic heating and cooling system often built into the viscometer or its accessories. It's convenient and offers rapid temperature changes and good stability. | A great option if lab space is limited or for cone and plate viscometers. Many of our Martests viscometers can be equipped with this. |

| Ambient Lab Control | This means trying to maintain a very stable air temperature in the lab. It's the least precise method. | This is only suitable for very rough estimates or non-critical applications. I would not recommend this for quality control or research. |

Always allow your sample to reach thermal equilibrium before taking a reading. This means letting it sit at the target temperature for a while, maybe 15-30 minutes or even longer for viscous samples in large containers. And always, always document the test temperature for every single measurement. This is a basic rule for good lab practice.

How Do Incorrect Spindle and Speed Choices Impact Viscosity Results?

Are your viscometer torque readings too high or too low? Using the wrong spindle or speed leads to inaccurate or even impossible measurements. Learn to select the optimal combination.

Incorrect spindle and speed choices lead to inaccurate viscosity. If torque is too low (e.g., <10%), results are imprecise. If too high (e.g., >90-100%), it's out of range. Select a combination giving mid-range torque.

Choosing the right spindle and rotational speed is fundamental for your rotational viscometer. Think of it like choosing the right gear on a bicycle. If you use too high a gear for a steep hill (like a low viscosity sample with a large spindle or high speed), you won't be able to pedal effectively. If you use too low a gear for a flat road (like a high viscosity sample with a small spindle or low speed), you'll spin your legs without much effect. We, as a factory, provide a range of spindles with our Martests rotating spindle viscometers to cover various viscosity ranges.

Understanding the Relationship

- Spindle Size and Shape: Larger spindles (those with more surface area) are generally used for lower viscosity fluids because they create more drag. Smaller spindles are for higher viscosity fluids. Our cone and plate viscometers, for instance, use specific geometries for certain sample types and shear rates.

- Rotational Speed (RPM): Higher speeds are generally used for lower viscosity fluids. Slower speeds are for higher viscosity fluids.

- Torque Percentage (%): This reading on your viscometer is your key indicator. It tells you how much rotational force (torque) is needed to turn the spindle at the set speed.

- If the torque is too low (e.g., below 10% or 20% of the instrument's full-scale range), the measurement is not very sensitive. Small variations won't be detected well, leading to imprecise results.

- If the torque is too high (e.g., above 90% or near 100%), the motor might be straining, or the sample's viscosity is simply beyond the measurable range for that specific spindle/speed combination. The reading will be inaccurate or show an error.

Making the Right Choice

The goal is to find a spindle and speed combination that gives a torque reading ideally in the mid-range of the instrument, say between 20% and 80%. Some people aim for 40-60% for the best accuracy.

| Sample's Estimated Viscosity | Spindle Size Recommendation | Speed Recommendation | Desired Torque Reading |

|---|---|---|---|

| Low | Larger | Higher | Aim for 20-80% |

| Medium | Medium | Medium | Aim for 20-80% |

| High | Smaller | Lower | Aim for 20-80% |

When I work with new customers, like a recent distributor from Southeast Asia looking to add our viscometers to their lab instrument portfolio, we always start by testing a range of spindle/speed combinations on their typical samples. If you're unsure, it's often best to start with a smaller spindle and a lower speed, then gradually increase the spindle size or speed until you get a stable, mid-range torque reading. Always record the spindle number and the speed used along with every viscosity result. This is crucial for reproducibility.

Why is Proper Sample Preparation Crucial for Accurate Viscosity Measurement?

Getting erratic viscosity readings even with the right settings? Inconsistent sample preparation can introduce hidden variables and ruin your results. Standardize your sample handling for reliable data.

Proper sample preparation is vital. Ensure samples are homogeneous, free of air bubbles, and at the correct temperature before testing. Inconsistent handling, like varying stirring or resting times, introduces errors.

What you do before you even bring the sample near the viscometer can significantly impact your measurement. I've seen many new users, especially those working with complex formulations like paints or cosmetics, struggle because of issues in sample preparation. It's not just about having a top-quality Martests viscometer; it's about the entire process leading up to the measurement. This insight is key for purchasing managers at large distributors who need to train their end-users.

Key Aspects of Sample Preparation

- Homogeneity: Is your sample thoroughly and uniformly mixed? For materials like suspensions, emulsions, or anything with multiple components, ensure there's no settling or separation. Any lack of uniformity means the spindle is measuring a non-representative part of the sample. Stir gently but completely. I often recommend a standardized stirring time and method for each sample type.

- Air Bubbles: These are a major enemy of accurate viscosity measurements. Air bubbles cause the spindle to encounter air pockets instead of a continuous liquid phase. This leads to artificially low and erratic readings. When pouring samples, do it slowly down the side of the beaker or container to minimize bubble formation. If bubbles are present, allow the sample to stand for a while to deaerate. For some of our clients dealing with very foamy products, we've suggested techniques like gentle centrifuging or applying a light vacuum to remove trapped air.

- Correct Sample Volume: Always use the correct volume of sample as specified for your viscometer and the beaker or sample chamber you are using. Our Martests coaxial cylinder viscometers, for example, have defined geometries that require a specific sample level for accurate results. Too little sample can lead to the spindle not being properly immersed or an incorrect shear environment. Too much can sometimes also affect flow patterns.

- Pre-Shear History (especially for Non-Newtonian fluids): Many fluids are "non-Newtonian," meaning their viscosity changes depending on how much they've been sheared (stirred, poured, mixed) before the measurement. Some fluids become thinner with shearing (thixotropic), while others might become thicker (rheopectic). For these types of materials, you must establish a consistent pre-shear protocol. For example, you might decide to shear the sample at a specific high rate for a set time, then let it rest for another set time before starting the actual viscosity measurement. A client in the food industry making sauces found their batch-to-batch viscosity varied wildly. The problem wasn't our viscometer; it was how different operators mixed and then let the sauce rest before testing. Standardizing this pre-treatment step solved their inconsistency.

How Does Viscometer Calibration and Maintenance Ensure Accurate Readings?

Doubting your viscometer's accuracy over time? Without regular checks and care, even top-quality instruments can drift, giving faulty data. Implement routine calibration and maintenance for precision.

Regular calibration using standard viscosity fluids verifies your viscometer's accuracy. Proper maintenance, like cleaning spindles and checking instrument level, prevents errors and prolongs its life, ensuring reliable results.

Your rotational viscometer is a precision instrument. Just like any high-performance tool, it needs regular care and checks to perform at its best. We at Martests build our viscometers, including rotating spindle, cone and plate, and coaxial cylinder types, to be robust and reliable. However, even the best instruments can experience drift or wear over time if not properly maintained and calibrated. For B2B wholesale, ensuring customers understand this helps them get the most value from our products.

Calibration: Your Accuracy Check

- Why Calibrate? Calibration verifies that your viscometer's torque measurement system and speed control are accurate. Essentially, it confirms that the viscosity readings your instrument provides are true and trustworthy.

- How Often? The frequency depends on how much you use the viscometer and how critical the measurements are. For heavy daily use in a quality control lab, monthly or even weekly calibration checks might be necessary. For less frequent use, perhaps quarterly or biannual checks would be sufficient. I always advise clients like Jacky, who customizes our viscometers with his logo and resells them, to recommend frequent calibration to his customers to maintain their confidence in the product.

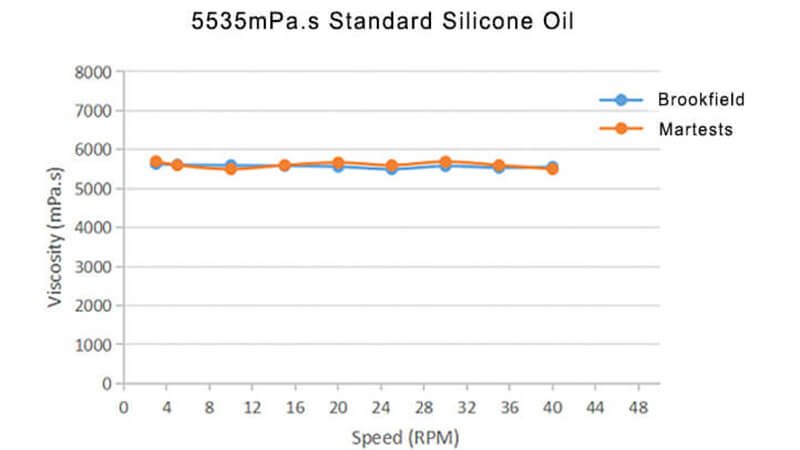

- Using Standard Fluids: Calibration is typically done using certified viscosity standard fluids. These are special oils (usually silicone-based) that have a precisely known viscosity at specific temperatures. You measure this standard fluid with your viscometer just like a normal sample. Then, you compare the reading your viscometer gives to the certified value of the standard fluid. If the reading is outside the acceptable tolerance (often +/- 1-2% of the standard's value, or as specified in your viscometer's manual), then the instrument may need adjustment or servicing. We can supply a range of these standard fluids.

Essential Maintenance Steps

A little routine care can go a long way in keeping your viscometer performing accurately for years.

| Task | Recommended Frequency | Importance & What to Do |

|---|---|---|

| Clean Spindles Thoroughly | After every single use | Any residue left on a spindle will dry and harden. This changes its dimensions and surface, affecting the drag it experiences and leading to false (usually high) viscosity readings. Use appropriate solvents that won't damage the spindle material. |

| Check Spindle Shaft | Regularly, before use | Ensure the spindle shaft is straight and not bent. A bent shaft will cause wobble during rotation, leading to erratic and incorrect readings. Handle spindles very carefully; don't drop them. |

| Level the Instrument | Before each use or session | Most viscometers have a bubble level. The instrument must be perfectly level for the spindle to hang vertically and rotate freely without friction against the guard leg (if present). |

| Inspect Bearings/Pivot | Annually or as needed | The bearings or pivot point that supports the spindle can wear over time. Worn bearings can cause increased friction, leading to inaccurate torque readings. Listen for any unusual noises during operation. |

Keeping your viscometer clean, handling its components with care, and performing regular calibrations are fundamental for trustworthy viscosity data. This is an investment in the quality and reliability of your work.

Conclusion

Consistent, accurate viscosity results come from careful temperature control, proper instrument setup, standardized sample handling, and regular viscometer maintenance. Master these for reliable data.

-

A circulating water bath can significantly improve your viscosity measurements by providing stable temperature conditions; learn more about its benefits. ↩