Struggling with inconsistent product quality? Your fluid's behavior changes from batch to batch, causing major headaches in production and for your customers who expect reliability.

Liquid viscosity is a measure of a fluid's resistance to flow, often called its "thickness." It is the most critical property for controlling how a liquid behaves during processing, application, and final use, directly impacting product quality and performance.

My name is Stefan Wang, and I'm the owner of Martests. We are a factory that manufactures high-quality viscometers. I talk to purchasing managers and lab specialists every day who need to solve real-world problems related to fluid behavior. They don't need complex theories; they need practical knowledge and reliable tools to get the job done. This guide breaks down everything you need to know about liquid viscosity in simple, direct terms. Let's dive in and give you the control you need over your products.

So, what exactly is viscosity in simple terms?

You hear the word "viscosity" but don't have a clear picture of what it means. This makes it hard to discuss product quality or troubleshoot issues with your team.

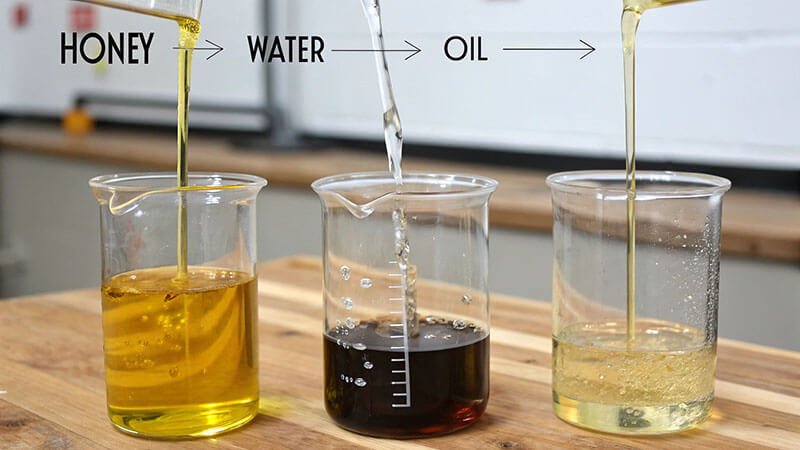

Viscosity is simply a fluid's internal friction. Think of it as the resistance you feel when stirring something. Stirring thick honey (high viscosity) is much harder than stirring thin water (low viscosity). This resistance is what we measure.

At its core, viscosity comes from the forces between the molecules inside a liquid. In a low-viscosity fluid like water, the molecules have weak connections, allowing them to slide past each other easily. This is why water flows freely. In a high-viscosity fluid like molasses or asphalt, the molecules have very strong connections. They stick together, creating a lot of internal friction that resists movement. This is why these fluids flow so slowly or not at all. Understanding this simple concept of internal friction is the first step to mastering your fluid's behavior. In manufacturing, controlling this property is essential. Whether you are making paint, food, or cosmetics, the viscosity determines how the product pumps through pipes, fills containers, and performs for the end-user. It is a direct indicator of consistency and quality.

What is Centipoise (cP) and why does it matter?

You need to describe your product's thickness, but words like "thick" or "thin" are not precise. This leads to misunderstandings with suppliers, customers, and your own quality control team.

Centipoise (cP) is the most common unit used to measure a fluid's viscosity. Using this standard unit ensures everyone is speaking the same language, which is essential for accurate quality control and clear communication in business.

How do we categorize liquid viscosity?

Your product doesn't fit a simple "thick" or "thin" label. You need a better way to classify it to select the right equipment and processing methods for your needs.

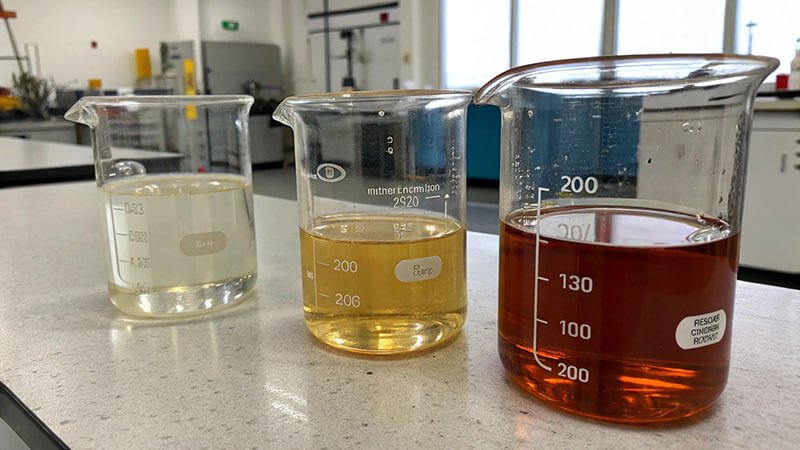

We generally categorize liquids into three main groups: water-like (low viscosity), semi-viscous (medium viscosity), and viscous (high viscosity). This classification helps you quickly understand your fluid and select the appropriate measurement tools and handling equipment.

Categorizing viscosity helps everyone from the purchasing manager to the line operator make better decisions. It provides a framework for understanding how a fluid will behave. For example, knowing you are working with a "viscous" material immediately tells you that you will likely need more powerful pumps and longer mixing times compared to a "water-like" fluid. At Martests, this classification directly impacts the viscometer we recommend to a client.

Here is a simple breakdown of these categories:

| Category | Description | Typical cP Range | Examples |

|---|---|---|---|

| Water-Like | Flows very freely, splashes easily. | 1 - 100 cP | Water, Milk, Solvents, Juices |

| Semi-Viscous | Pours slower, has some body. | 100 - 5,000 cP | Motor Oil, Syrups, Lotions |

| Viscous | Flows very slowly, thick and sticky. | > 5,000 cP | Honey, Ketchup, Gels, Pastes |

This table is a great starting point. When a new customer contacts me, one of the first questions I ask is about their product's expected viscosity. Their answer helps me guide them toward the right viscometer series—LV for low viscosity, RV for medium, or HV for high viscosity.

What are some common centipoise ratings?

You know what centipoise is, but you lack real-world reference points. This makes it hard to judge if your product's viscosity reading is reasonable or what target you should aim for.

Knowing the centipoise ratings of everyday items gives you a practical scale for comparison. Water is 1 cP, olive oil is about 85 cP, and honey is around 10,000 cP. This context makes your own measurements meaningful.

Having a mental library of common viscosity values is incredibly useful. It helps you quickly estimate the category your product falls into and whether the measurements from your viscometer make sense. It also helps in product development when you are trying to match the texture of a competitor's product. For example, if you are developing a new cosmetic cream and want it to feel as rich as a market-leading brand, you can measure that brand's viscosity and set it as your target. Here is a more detailed list of common fluids and their approximate viscosity in centipoise (cP) at room temperature (around 20-25°C).

| Substance | Typical Viscosity (cP) |

|---|---|

| Water | 1 cP |

| Milk | 3 cP |

| Olive Oil | 85 cP |

| SAE 30 Motor Oil | 200 cP |

| Maple Syrup | 300 cP |

| Ketchup | 50,000 cP |

| Toothpaste | 100,000 cP |

| Peanut Butter | 250,000 cP |

Remember, these are just typical values. The exact viscosity can change based on the specific formulation and, most importantly, temperature.

How does temperature affect a liquid's viscosity?

Your viscosity readings are inconsistent, and you can't figure out why. This makes quality control a nightmare and leads to unreliable data that you can't trust for decision-making.

For most liquids, viscosity has an inverse relationship with temperature. As the temperature goes up, the viscosity goes down (it gets thinner). Controlling temperature during measurement is absolutely critical for getting accurate and repeatable results.

This is one of the most important lessons I teach my clients. I once had a customer who made industrial coatings. His team got a very high viscosity reading in the morning and a much lower one in the afternoon for the same batch. They thought their viscometer was broken. The problem was simple: their lab was cold in the morning and much warmer in the afternoon after the sun had been shining on it. The change in the sample's temperature was causing the massive shift in viscosity. Once they started using a temperature-controlled water bath to keep their samples at a constant 25°C, their readings became stable and reliable. This is why professional viscometers, including the ones we build at Martests, often have ports for circulating water from a temperature bath or have integrated temperature probes. You must always record the temperature alongside the viscosity reading. A value of "5,000 cP" is meaningless. A value of "5,000 cP at 25°C" is useful, repeatable data.

How is viscosity actually measured in a lab?

You know you need to measure viscosity, but the process seems complex. You worry about getting it wrong and making decisions based on bad data, which could be very costly.

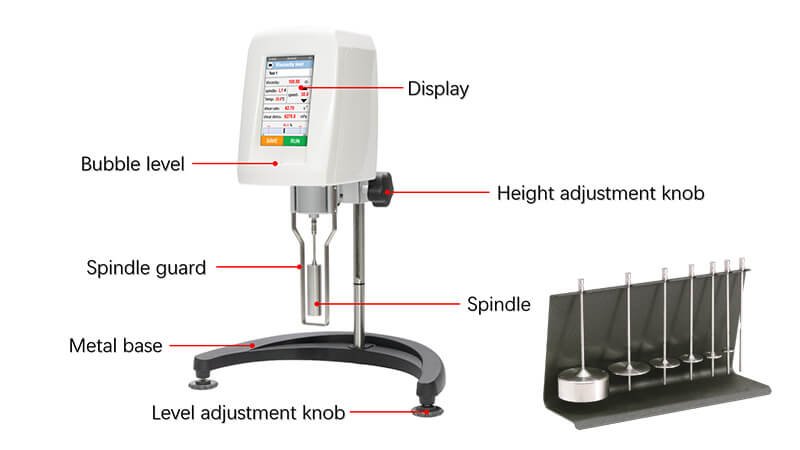

Viscosity is measured with an instrument called a viscometer. The most common type, a rotational viscometer, works by rotating a spindle in the fluid and measuring the torque (resistance) required to keep it spinning at a constant speed.

The process is more straightforward than it sounds. Imagine dipping a spinning metal rod (we call it a spindle) into a beaker of your product. If your product is thin like water, the spindle will spin easily, and the viscometer's motor won't have to work very hard. The instrument measures this low effort, or low torque. If your product is thick like a gel, the motor has to work much harder to keep the spindle spinning at the same speed. The instrument measures this high effort, or high torque. The viscometer's internal software then uses this torque reading, combined with the known size and shape of the spindle and its speed, to calculate the precise viscosity value in centipoise (cP). The key to getting a good measurement is choosing the correct spindle and speed combination for your fluid. The goal is to get a torque reading that is within the instrument's ideal range, typically between 10% and 100%.

What is a viscometer and how does it work?

You need to buy a viscometer, but the options are overwhelming. Choosing the wrong one is an expensive mistake that won't solve your quality control problems and will just gather dust.

A viscometer is the essential tool for measuring fluid viscosity. A rotational viscometer uses a motor to rotate a spindle in a liquid, measures the resistance, and calculates the viscosity, giving you precise, actionable data for quality control.

At Martests, we are a factory specializing in rotational viscometers because they are versatile, reliable, and provide the accuracy most industries need. The core components are simple: a calibrated motor that provides precise rotational speeds, a set of interchangeable spindles of different shapes and sizes, and a sensor that measures the torque. When you purchase from us, we help you select the right model. For water-like liquids, you need an LV (Low Viscosity) model. For medium-thick materials like paints or lotions, an RV (Regular Viscosity) model is best. For very thick pastes and gels, you need an HV (High Viscosity) model. We also provide the necessary accessories, like different spindle sets and temperature control baths. Because we are the factory, we can offer top quality and also customize the instruments with our customers' logos. This is perfect for distributors like Jacky in Italy, who can build their own brand with reliable instruments that we manufacture.

Conclusion

Understanding liquid viscosity, centipoise, and temperature effects is crucial. Using the right viscometer from Martests gives you the precise control needed for consistent product quality and operational efficiency.