NTV-CAP1 Cone and Plate Viscometer

Optimize your viscosity measurements with the NTV-CAP1 Cone and Plate Viscometer, providing dependable precision and versatility for a range of laboratory needs.

- Maximum Range Up to 7,800,000 cP

- Accuracy: ±1%

NTV-CAP1 Viscosity Range

Viscosity unit conversion: 1Pa.s=1000mPa.s, 1P=100mPa.s, 1mPa.s=1cP, M=1,000,000, K=1,000, FS=Full Scale.

| Spindle No. | Shear Rate | Sample Volume | NTV-CAP1LV (RPM: 0.1-250) | NTV-CAP1RV (RPM: 0.1-250) | NTV-CAP1HA (RPM: 0.1-250) | NTV-CAP1HB (RPM: 0.1-250) |

|---|---|---|---|---|---|---|

| CPE-40 | 7.5N | 0.5ml | 0.1-3,000 mPa.s | 1-32,000 mPa.s | 2.6-65,000 mPa.s | 10.5-261,000 mPa.s |

| CPE-41 | 2.0N | 2.0ml | 0.5-11,000 mPa.s | 5-122,000 mPa.s | 10-245,000 mPa.s | 39-982,000 mPa.s |

| CPE-42 | 3.84N | 1.0ml | 0.2-6,000 mPa.s | 2-64,000 mPa.s | 5-128,000 mPa.s | 20-512,000 mPa.s |

| CPE-51 | 3.84N | 0.5ml | 2-48,000 mPa.s | 20-512,000 mPa.s | 41-1M mPa.s | 163-4M mPa.s |

| CPE-52 | 2.0N | 0.5ml | 3-92,000 mPa.s | 39-983,000 mPa.s | 78-2M mPa.s | 314-7.8M mPa.s |

Technical Specifications

| Item | Description | |||||

|---|---|---|---|---|---|---|

| Accuracy | ±1% (Newtonian fluid FS) | |||||

| Temperature Low | -5℃~-120℃ | |||||

| Temperature High | RT+5℃~+250℃ | |||||

| Temperature Accuracy | ±0.1℃ | |||||

| Power Supply | 100V-240V | |||||

| Optional Accessories | • Standard Oil • DV Software | |||||

Accessories Solutions

Unlock more testing possibilities with our professional accessories – designed to expand your viscometer’s capabilities.

Viscosity Standards

Viscosity standard solution of silicone oil type is used for the calibration of your viscometer, which is convenient to use and reliable in data.

- 450ml per bottle

- 5 cP, 50 cP, 340 cP, 1800 cP, 6190 cP, 9757 cP

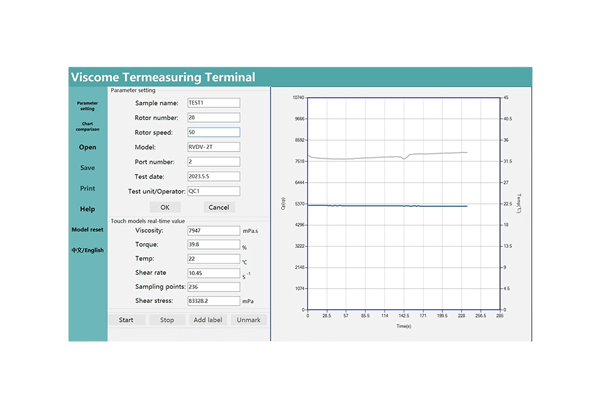

DV Software

DV Software for Viscometers enhances viscosity measurement by providing real-time data tracking, customizable reporting, and improved workflow efficiency.

Effectively Manage Quality Issues

Learn how we address rework and returns to maintain the highest quality standards and ensure customer satisfaction.

Reasons for Rework

- Failure to Meet Precision Requirements

- Design or Manufacturing Defects

- Software Malfunctions

Reasons for Replacement

- Critical Component Failure

- Persistent Performance Issues

- Equipment Incompatibility