Your paint sags, settles, or sprays unevenly. These issues ruin the final finish and waste material, costing you time and money with unhappy customers.

Rheology is the science of how materials flow. In paints, it controls everything from storage stability and application ease to sag resistance and final appearance. Mastering rheology is the key to creating a high-quality, predictable product.

I often talk with my customers, like Jacky in Italy, about this exact topic. He sells to many paint manufacturers. They don't just want a viscometer from me; they want a solution to their problems. They want to know why their paint isn't behaving correctly on the wall. The answer almost always comes back to rheology. It's a big word, but the ideas behind it are practical and essential for anyone in the coatings industry. Let's break it down together.

What is Rheology and Why Does it Matter in Coatings?

You see the term "rheology" but think it’s just about how thick or thin a paint is. This oversimplification leads to poor formulation choices and inconsistent product performance.

Rheology is the study of flow and deformation. For paints, it's critical because it dictates how the product behaves during storage, application, and drying. Good rheology ensures the paint is easy to use and provides a flawless finish.

A can of paint has to do many different jobs, and they often contradict each other. It needs to be thick in the can so pigments don't settle. But it needs to be thin when you brush it so it spreads easily. Then, it needs to get thick again on the wall so it doesn't drip. Simple "viscosity" can't describe this complex behavior. This is the world of rheology. At my company, Martests, we build the rotational viscometers that measure these properties. But before you can measure it, you have to understand what you're looking for.

More Than Just Thick or Thin

Thinking of paint as just "thick" or "thin" is a common mistake. Viscosity is a single measurement at one point in time. Rheology is the whole story. It describes how the viscosity changes when you apply force, like when you stir it, brush it, or spray it. A perfect paint must have different viscosities at different stages. This ability to change is what separates a high-quality coating from a cheap one.

How Rheology Affects Product Performance

The entire life of a paint is governed by its rheology. From the moment it's made to the final dried film, its flow properties determine its success or failure.

| Stage | Desired Behavior | Rheological Need |

|---|---|---|

| Storage | Pigment doesn't settle at the bottom. | High viscosity at rest (low shear). |

| Application | Spreads easily with a brush or sprayer. | Low viscosity under force (high shear). |

| Leveling | Brush marks disappear. | Temporary low viscosity after application. |

| Curing | Doesn't sag or drip on the wall. | Quick viscosity recovery to resist gravity. |

Understanding this table is the first step to solving real-world paint problems. Every one of these behaviors can be measured and controlled.

What are the Fundamental Rheological Concepts for Paints?

You hear jargon like "thixotropy" and "yield stress" and feel confused. Without knowing these concepts, you can't properly diagnose paint problems or understand a technical data sheet.

Key concepts include shear thinning (viscosity decreases with stress, like brushing) and thixotropy (a time-dependent recovery). These properties, plus yield stress, determine how a paint flows, levels, and resists sagging, making them crucial for formulators.

When I first got into this business, these words sounded very academic. But they describe things every painter experiences. They are the scientific names for the "feel" of a good paint. Once you understand them, you can move from guessing to engineering your product's performance.

Viscosity vs. Rheology – What’s the difference?

Let me make this very clear. Viscosity is one number. For example, the viscosity of water at 20°C is about 1 centipoise. It doesn't change if you stir it slowly or quickly. Rheology is for materials like ketchup. It's thick in the bottle (high viscosity), but when you shake it (apply shear), it becomes thin and flows easily. Paint is like ketchup, not water. A simple viscometer might give you one number, but a rotational viscometer from Martests can generate a flow curve, which tells the whole rheological story.

Key Rheological Behaviors Explained

These terms are the language of paint formulation. Let's define them in a simple way.

| Term | Simple Definition | Paint Example |

|---|---|---|

| Shear Rate | The speed of force you apply. | Low shear = sitting in the can. High shear = fast brushing. |

| Shear Thinning | Gets thinner when you apply force. | The paint flows easily off the brush but is thick in the can. |

| Thixotropy | Gets thinner with force, and slowly thickens again over time. | Gives the paint a few seconds to level before it starts to resist sagging. |

| Yield Stress | The minimum force needed to make the paint start flowing. | This is what holds the paint on the wall against gravity. |

These are not separate properties. They all work together. A great paint has the perfect balance of shear thinning, thixotropy, and yield stress.

What is the Practical Role of Rheology in Paint Performance?

Your paint looks good in the can but performs poorly during and after application. This mismatch between formulation and real-world function leads to unhappy customers and product failures.

Rheology governs four key areas: storage stability (preventing pigment settling), application ease (ensuring easy brushing or spraying), sag resistance (preventing drips), and final appearance (promoting a smooth, defect-free surface).

A customer opens a can of paint and has certain expectations. They expect it to be uniform, easy to apply, and to look great when it's dry. Rheology is the invisible property that ensures all of these expectations are met. Let's look at each stage.

Storage Stability and Pigment Suspension

A paint is a suspension of solid pigment particles in a liquid binder. Over time, gravity wants to pull those heavy pigments to the bottom of the can. This is called settling. To prevent this, the paint needs to have a high viscosity when it is at rest (in the can on a shelf). Specifically, it needs a high enough yield stress to build an internal structure that holds the pigments in place. When the customer opens the can after six months, it should look uniform and ready to use with minimal stirring. This is the first test of good rheology.

Application, Leveling, and Sag Resistance

This is where things get interesting. The high viscosity that was great for storage is terrible for application. To solve this, paints are designed to be shear-thinning.

- Application: When you apply the paint with a brush or a sprayer, you are applying a high shear rate. This force breaks down the paint's internal structure, causing its viscosity to drop dramatically. The paint flows easily and smoothly.

- Leveling and Sag: The moment you lift the brush, the shear rate drops to almost zero. Now, the internal structure starts to rebuild, and the viscosity increases. This is thixotropy. If the viscosity recovers too quickly, it traps brush marks, resulting in poor leveling. If it recovers too slowly, the paint remains thin for too long and will drip or sag under gravity. The perfect paint gives itself just enough time to level out before it thickens up to resist sagging. This is the magic of a well-formulated coating.

How is Rheology Measured in Paints and Coatings?

You know rheology is important, but you don't know how to measure it effectively. Without the right data, you're just guessing at your formulation and hoping for the best.

Rheology is measured with rotational viscometers or rheometers. These instruments apply controlled shear rates to a sample and measure its resistance (viscosity). This data is plotted on a flow curve to analyze behaviors like shear thinning and thixotropy.

This is my area of expertise. My factory, Martests, produces the tools that turn these concepts into numbers. When a customer like Jacky asks for a viscometer for a paint company, I know they need more than a single-point measurement. They need to understand the full behavior of their product.

Common Rheological Tests and Instruments

The primary tool for this is a rotational viscometer. It works by rotating a spindle in the paint sample at different speeds and measuring the torque required. This allows us to build a picture of the paint's rheology. For even more detailed analysis, an R&D lab might use a rheometer, which offers even more control and can measure properties like viscoelasticity (G' and G").

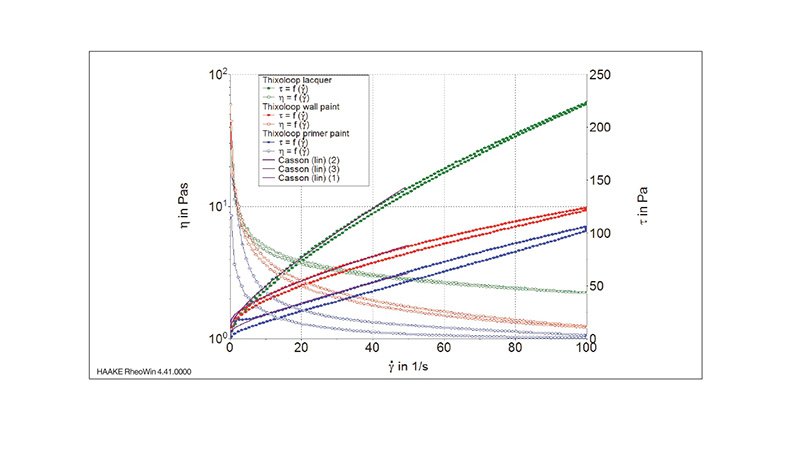

The most useful test for paints is generating a flow curve.

- The instrument starts at a low rotation speed (low shear rate) and gradually increases to a high speed.

- It then reverses, going from high speed back down to low speed.

- Plotting viscosity against shear rate for this whole process reveals shear thinning (viscosity drops as speed increases) and thixotropy (the up-curve and down-curve don't overlap, creating a "thixotropic loop"). The area of this loop tells you about the time-dependent structural breakdown and recovery.

Case Study: Predicting Real-World Performance

Imagine we test two paints with one of my viscometers.

- Paint A shows a large thixotropic loop and a high viscosity at low shear rates. This tells me the paint will be excellent at resisting sag on a vertical wall. Its structure rebuilds quickly and strongly. However, it might not have great leveling, as brush marks could be "frozen" in place before they have time to flow out.

- Paint B shows a much smaller thixotropic loop. Its structure rebuilds more slowly. I can predict that this paint will have fantastic leveling properties, creating a very smooth, glass-like finish. But, an applicator must be careful not to apply it too thickly, or it will sag.

This is how the data from our instruments gives formulators real power. They can directly link a number on a screen to performance on a wall.

Conclusion

In summary, mastering rheology is not an option in the coatings industry; it is a necessity. Proper measurement and control lead directly to superior product quality and performance.