Confused by oil numbers like 5W-30 or 75W-90? This confusion can lead to wrong lubricant choices. I'll simplify SAE viscosity grades for you.

SAE viscosity grades classify oils by their flow characteristics at different temperatures. The "W" indicates winter/low-temperature performance, while the second number (if present) relates to high-temperature performance.

Choosing the right oil is crucial for any engine or gear system. But those SAE viscosity grades on the bottle can look like a secret code. As someone at Martests, where we manufacture viscometers, I often talk with clients like Jacky, a distributor in Italy. He knows his customers need clarity on these grades to pick the best lubricants. If you've ever wondered what "5W-30" or "SAE 90" really means, you're in the right place. This article will break down SAE viscosity grades so you can understand them easily. We'll look at what the numbers signify and why they matter for keeping machinery running smoothly.

What are SAE Viscosity Grades in General?

Do terms like "SAE 30" or "10W-40" leave you guessing about oil thickness? Misunderstanding these grades can cause premature wear and tear on valuable equipment.

SAE viscosity grades are standards set by SAE International (formerly the Society of Automotive Engineers) to define an oil's resistance to flow (viscosity) at specific temperatures, ensuring proper lubrication.

At its heart, an SAE viscosity grade tells you how "thick" or "thin" an oil is, or more technically, its viscosity. Think of honey versus water. Honey is more viscous; it resists flowing more than water does. Oils behave similarly, and their viscosity changes with temperature. They get thinner when hot and thicker when cold.

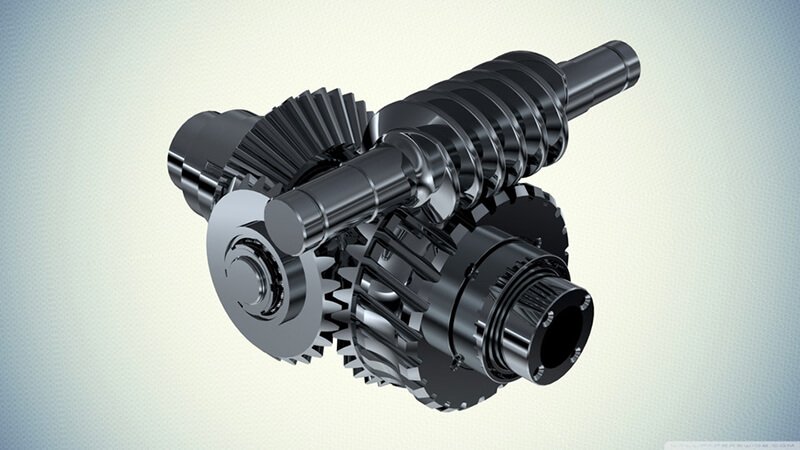

The SAE developed these grading systems to provide a standardized way for everyone – from oil manufacturers to equipment operators – to know an oil's flow characteristics. There are actually two main SAE standards for viscosity grades that we deal with often at Martests:

- SAE J300: This standard covers engine oils.

- SAE J306: This standard covers automotive gear lubricants (like those for transmissions and differentials).

It's important to note that an engine oil grade (e.g., SAE 30) and a gear oil grade (e.g., SAE 90) are on different scales. So, an SAE 90 gear oil is not three times thicker than an SAE 30 engine oil. In fact, they can be quite similar in actual viscosity. We'll explore this more later. The key takeaway is that these grades help you choose an oil that will flow correctly at both engine startup (cold) and operating (hot) temperatures. Our viscometers play a crucial role in ensuring oils meet these precise SAE specifications.

What do those "W" numbers on engine oil really mean?

Ever wondered if the "W" in 5W-30 stands for "Weight"? This common mistake can lead to using oil too thick for cold starts, stressing your engine.

The "W" in SAE engine oil grades stands for "Winter." It indicates the oil's viscosity performance at low temperatures, ensuring it flows well enough for cold starting and lubrication.

When you see an engine oil grade like SAE 5W-30, SAE 10W-40, or even a monograde like SAE 10W, that "W" is super important. It doesn't stand for "Weight," as many people think. It stands for "Winter." This part of the grade tells you how the oil behaves in cold conditions. At Martests, we often explain to our distributors that this is critical because if an oil is too thick when cold, it can cause several problems:

- Hard Starting: The engine starter will struggle to crank a cold engine if the oil is like molasses.

- Poor Cold Lubrication: Thick oil takes longer to reach critical engine parts, leading to increased wear during the first few moments after starting.

The SAE J300 standard specifies two key low-temperature tests for "W" grades:

- Cranking Viscosity (CCS - Cold Cranking Simulator): This measures the oil's resistance to cranking at low temperatures. The lower the "W" number (e.g., 0W, 5W, 10W), the better the oil performs in this test at colder temperatures.

- Pumping Viscosity (MRV - Mini-Rotary Viscometer): This test ensures the oil can be pumped by the oil pump to the engine's vital parts even when very cold. If oil fails this, it might seem to flow but won't actually get pumped, leading to oil starvation. Our rotational viscometers, including those with low-temperature capabilities, are essential for these measurements.

Here's a simplified look at some "W" grades and their low-temperature performance:

| SAE "W" Grade | Max Cranking Viscosity (mPa·s or cP) @ Temp (°C) | Max Pumping Viscosity (mPa·s or cP) @ Temp (°C) (No Yield Stress) |

|---|---|---|

| 0W | 6200 @ -35°C | 60,000 @ -40°C |

| 5W | 6600 @ -30°C | 60,000 @ -35°C |

| 10W | 7000 @ -25°C | 60,000 @ -30°C |

| 15W | 7000 @ -20°C | 60,000 @ -25°C |

| 20W | 9500 @ -15°C | 60,000 @ -20°C |

| 25W | 13000 @ -10°C | 60,000 @ -15°C |

The lower the "W" number, the colder the temperature at which the oil can still perform these critical functions.

And what about the second number in engine oil, like the "30" in 5W-30?

Is a higher second number always better for engine protection? Assuming this can lead to using oil too thick at operating temperatures, reducing fuel efficiency.

The second number in a multigrade engine oil (e.g., the "30" in 5W-30) defines the oil's kinematic viscosity at operating temperature (100°C), ensuring it's thick enough to protect hot engine parts.

Once your engine is warmed up and running, the oil's behavior at higher temperatures becomes critical. This is where the second number in a multigrade oil (like the "30" in SAE 5W-30, or the "40" in SAE 10W-40) comes into play. For monograde oils without a "W" (like SAE 30 or SAE 40), this single number defines its high-temperature viscosity.

This number relates to the oil's kinematic viscosity, measured in centistokes (cSt) or mm²/s, at 100°C (212°F), which is a typical engine operating temperature. The oil needs to be thick enough at this temperature to maintain a protective film between moving parts, preventing metal-to-metal contact and wear. If it's too thin, it won't offer adequate protection. If it's too thick, it can increase internal friction, reduce fuel economy, and may not flow quickly enough to smaller passages.

The SAE J300 standard also specifies a minimum High-Temperature/High-Shear (HTHS) viscosity at 150°C. This test simulates the conditions in an engine's tightest, hottest spots, like bearings. It's a better indicator of an oil's ability to protect under extreme stress. Our viscometers, especially cone and plate viscometers, are used to measure HTHS viscosity.

Here's a simplified table showing common operating temperature viscosity grades:

| SAE Operating Temp Grade | Kinematic Viscosity @ 100°C (cSt or mm²/s) | Min. HTHS Viscosity @ 150°C (mPa·s or cP) |

|---|---|---|

| 16 | 5.6 to < 6.9 | 2.3 |

| 20 | 6.9 to < 9.3 | 2.6 |

| 30 | 9.3 to < 12.5 | 2.9 (for 0W, 5W, 10W grades); 3.5 (for others) |

| 40 | 12.5 to < 16.3 | 2.9 (for 0W, 5W, 10W grades); 3.5 or 3.7 (for others) |

| 50 | 16.3 to < 21.9 | 3.7 |

| 60 | 21.9 to < 26.1 | 3.7 |

So, an SAE xW-30 oil must meet the low-temperature requirements of its "W" grade (e.g., 5W) and the high-temperature kinematic viscosity range of an SAE 30 oil. This dual characteristic is what makes multigrade oils so versatile.

Why are gear oil SAE numbers (like 75W-90) so different from engine oil numbers?

Do higher numbers on gear oil mean it's always much thicker than engine oil? This common misconception can cause confusion when selecting lubricants for different applications.

Gear oil SAE grades (e.g., 75W-90, from SAE J306) use a different scale than engine oil grades (SAE J300). An SAE 75W-90 gear oil can have similar actual viscosity to an SAE 10W-40 engine oil.

This is a point that often confuses people, even some in the industry! When you see a gear oil like SAE 75W-90 or SAE 80W-90, the numbers look much higher than typical engine oil grades like SAE 10W-40. It's natural to assume the gear oil is incredibly thick. However, this is not necessarily true because engine oils and gear oils are graded on different SAE scales (J300 for engine, J306 for gear).

The reason for the separate scales is historical and relates to the different operating conditions and requirements of engines versus gearboxes. Gear oils often need to handle extreme pressures (EP additives are common) and different shear conditions.

Just like engine oils, gear oils can be monograde (e.g., SAE 90) or multigrade (e.g., SAE 75W-90).

- The "W" still indicates winter/low-temperature performance. For gear oils, the J306 standard specifies the maximum temperature at which the oil will have a viscosity of 150,000 cP (measured with a Brookfield type viscometer, similar to how our rotating spindle viscometers work).

- The second number (e.g., the "90" in 75W-90) refers to the kinematic viscosity at 100°C.

Let's look at a simplified comparison to illustrate: - An SAE 75W-90 gear oil typically has a kinematic viscosity at 100°C between 13.5 and 24.0 cSt.

- An SAE 10W-40 or SAE 15W-40 engine oil typically has a kinematic viscosity at 100°C between 12.5 and 16.3 cSt.

You can see that an SAE 75W-90 gear oil isn't wildly thicker than a common heavy-duty engine oil at operating temperature. The main point I stress to clients like Jacky is not to directly compare the numbers across the two standards. Always refer to the equipment manufacturer's recommendation for the correct SAE grade and type of oil.

Here's a simplified table for some common gear oil grades:

| SAE Gear Oil Grade | Max Temperature for 150,000 cP Viscosity (°C) | Kinematic Viscosity @ 100°C (cSt or mm²/s) |

|---|---|---|

| 70W | -55 | 3.8 to < 5.7 |

| 75W | -40 | 3.8 to < 5.7 |

| 80W | -26 | 7.0 to < 11.0 |

| 85W | -12 | 11.0 to < 13.5 |

| 80 | N/A (No W grade) | 7.0 to < 11.0 |

| 85 | N/A (No W grade) | 11.0 to < 13.5 |

| 90 | N/A (for monograde, like 75W-90) | 13.5 to < 18.5 |

| 110 | N/A (for monograde, like 80W-110) | 18.5 to < 24.0 |

| 140 | N/A (for monograde, like 85W-140) | 24.0 to < 32.5 |

Understanding these distinctions is key for proper lubricant selection.

How do viscometers ensure these SAE grades are met?

Can you just trust the label on an oil bottle? Without proper testing using viscometers, there's no guarantee the oil actually meets the claimed SAE viscosity grade.

Viscometers are essential laboratory instruments used to precisely measure an oil's viscosity at various temperatures, ensuring it meets the strict criteria defined by SAE J300 and J306 standards for each grade.

The SAE viscosity grades are not just arbitrary numbers; they are backed by precise viscosity limits measured at specific temperatures. This is where instruments like the viscometers we produce at Martests come into play. Oil manufacturers, blending plants, and independent testing labs rely heavily on accurate viscometry to:

- Formulate Oils: When developing new oil formulations, chemists use viscometers to fine-tune the blend of base oils and additives (like Viscosity Index Improvers) to achieve the desired SAE grade characteristics across a range of temperatures.

- Quality Control (QC): This is a huge area. Every batch of oil produced needs to be tested to confirm it meets the specified SAE grade. If an "SAE 5W-30" oil doesn't meet the 5W cold-cranking specs or the SAE 30 high-temperature specs, it can't be sold as such. Our clients, who are often distributors supplying these labs or manufacturers, understand the critical need for reliable QC instruments.

- Research and Development: Pushing the boundaries of lubricant performance – for better fuel economy, longer drain intervals, or enhanced protection – involves a deep understanding and precise measurement of rheological properties.

Different types of viscometers are used for different SAE tests:

- Cold Cranking Simulators (CCS): A specialized rotational viscometer for low-temperature cranking viscosity.

- Mini-Rotary Viscometers (MRV): Another specialized rotational viscometer for low-temperature pumping viscosity.

- Capillary Viscometers (or automated versions): Used for determining kinematic viscosity at 100°C.

- Rotational Viscometers (like cone and plate): Used for High-Temperature/High-Shear (HTHS) measurements. Our cup and bob viscometers also play a role in characterizing various fluid behaviors relevant to oil formulation.

I remember a conversation with a purchasing manager for a large distributor. He was sourcing viscometers for a new lab his company was setting up in Southeast Asia. He emphasized how crucial it was for his customers – local oil blenders – to have instruments that provided accurate and repeatable results, ensuring their products met both SAE standards and the expectations of end-users. Without precise viscosity measurement, the entire SAE grading system would be meaningless.

Conclusion

SAE viscosity grades classify oil flow at different temperatures. Understanding them ensures correct lubricant choice, vital for engine and gear health, which our Martests viscometers help verify.