Are you struggling with product inconsistencies or processing inefficiencies? Choosing the wrong viscosity measurement for your application can lead to costly manufacturing errors and quality control failures.

Viscosity comes in several distinct types: dynamic (absolute) viscosity measures fluid's internal resistance to flow; kinematic viscosity accounts for density effects; steady shear (apparent) viscosity applies to non-Newtonian fluids; relative viscosity compares fluids to a standard; and extensional viscosity measures resistance to stretching rather than flowing.

I recently visited a cosmetics manufacturer in Italy who was puzzled by inconsistent product performance despite "good" viscosity readings. After examining their process, I discovered they were using kinematic viscosity measurements for a highly non-Newtonian cream. Once we switched to measuring steady shear viscosity with one of our rotating spindle viscometers, they were able to identify and correct variations in their formulation. The right viscosity measurement doesn't just provide numbers—it gives you actionable insights that directly impact your product quality and production efficiency.

Dynamic (Absolute) Viscosity: When Should I Use This Fundamental Measurement?

Are you uncertain which viscosity measurement to start with for your fluid analysis? Selecting the wrong fundamental parameter can lead to misinterpreted data and flawed product development decisions.

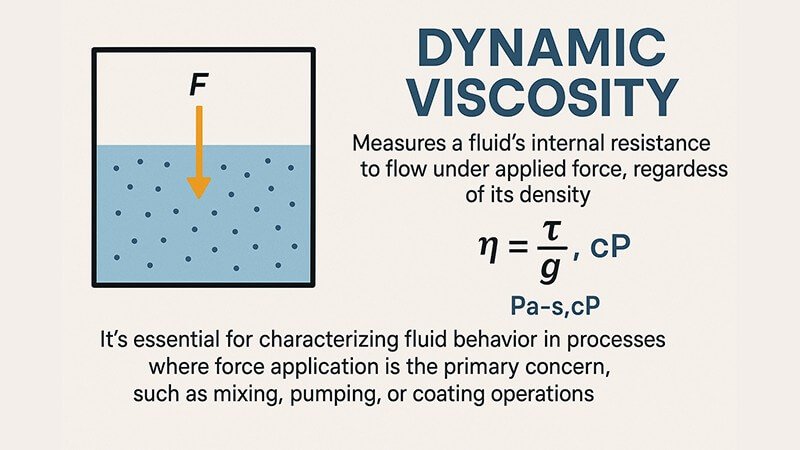

Dynamic viscosity, also called absolute viscosity, measures a fluid's internal resistance to flow under applied force, regardless of its density. Measured in Pascal-seconds (Pa·s) or centipoise (cP), it's essential for characterizing fluid behavior in processes where force application is the primary concern, such as mixing, pumping, or coating operations.

Dynamic viscosity forms the foundation of all viscosity measurements. When I train new customers on our Martests viscometers, I always start with this concept because it directly represents how much force is needed to move your fluid at a specific rate.

Think of dynamic viscosity as the "effort" required to stir your product. This is particularly important in processes where energy consumption matters. For example, I worked with a paint manufacturer in Southeast Asia who was concerned about mixer motor sizing for a new production line. By measuring the dynamic viscosity of their formulations, we helped them select appropriately powered mixing equipment that avoided both underpowered failures and energy-wasting oversizing.

The units for dynamic viscosity can sometimes cause confusion. The SI unit is the Pascal-second (Pa·s), but many industries still use the centipoise (cP), with 1 Pa·s equal to 1,000 cP. To put these values in context, water at room temperature has a dynamic viscosity of about 1 cP (0.001 Pa·s), while honey might be around 10,000 cP (10 Pa·s).

Dynamic viscosity is typically measured using rotational viscometers like our spindle models, where torque required to rotate a spindle in fluid at a known speed correlates directly with dynamic viscosity. These measurements are particularly valuable for quality control applications where you need to ensure batch-to-batch consistency.

One key advantage of measuring dynamic viscosity is that it's independent of the fluid's density, making it ideal for comparing the "thickness" of different fluids directly. This becomes especially important when formulating products where the "feel" or application properties are critical, such as lotions, lubricants, or adhesives.

I remember helping a Middle Eastern distributor whose customer manufactured lubricating oils. They switched to measuring dynamic viscosity for their blending process, which allowed them to detect subtle changes in their base oil supplies that would have gone unnoticed with their previous methods. This early detection prevented substantial processing problems downstream.

Kinematic Viscosity: Why Does Density Matter in Flow Behavior?

Have you noticed your fluid behaves differently than expected despite having the "right" viscosity? Overlooking the relationship between viscosity and density can cause significant processing problems and product failures.

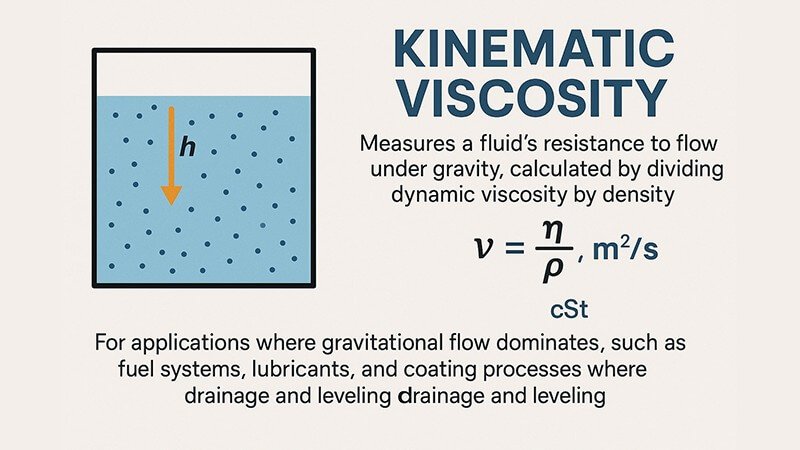

Kinematic viscosity measures a fluid's resistance to flow under gravity, calculated by dividing dynamic viscosity by density. Measured in units of square meters per second (m²/s) or centistokes (cSt), it's crucial for applications where gravitational flow dominates, such as fuel systems, lubricants, and coating processes where drainage and leveling are important.

Kinematic viscosity becomes relevant when gravity plays a significant role in your fluid's behavior. I often explain to customers that while dynamic viscosity tells you how "thick" a fluid feels, kinematic viscosity tells you how quickly it will flow under its own weight.

The relationship is straightforward: kinematic viscosity = dynamic viscosity ÷ density. This measurement is particularly important in industries like petroleum, where standardized testing using capillary viscometers is common. These tests measure how long it takes for a specific volume of fluid to flow through a calibrated glass tube under gravity, directly correlating to kinematic viscosity.

In practical terms, two fluids might have identical dynamic viscosity but behave very differently due to density differences. I once consulted for a coatings company in South America that was experiencing inconsistent film thickness with a new formulation. Their dynamic viscosity measurements looked perfect, but when we measured kinematic viscosity, we discovered significant variations that explained the uneven coating performance.

Here's how kinematic viscosity typically applies across different industries:

| Industry | Kinematic Viscosity Application | Typical Range (cSt) |

|---|---|---|

| Petroleum | Fuel flow in engines, pipelines | 1-20 |

| Lubricants | Oil performance classification | 20-500 |

| Coatings | Sagging, leveling prediction | 50-10,000 |

| Food | Pouring behavior of liquids | 1-5,000 |

ASTM D445 is the standard test method for kinematic viscosity of transparent and opaque liquids, using glass capillary viscometers. For customers who need both dynamic and kinematic measurements, we often recommend determining dynamic viscosity with our rotational viscometers and then calculating kinematic viscosity after a simple density measurement.

Temperature sensitivity is particularly important for kinematic viscosity, as both dynamic viscosity and density change with temperature. For instance, the viscosity index (VI) of lubricating oils—which indicates how much viscosity changes with temperature—is determined through kinematic viscosity measurements at different temperatures. I always recommend precise temperature control when measuring kinematic viscosity, as even small temperature variations can significantly impact results.

Steady Shear (Apparent) Viscosity: How Do I Measure Non-Newtonian Behavior?

Is your product showing inconsistent processing characteristics despite passing traditional viscosity checks? Not accounting for shear-dependent behavior can result in product failures and wasted production runs.

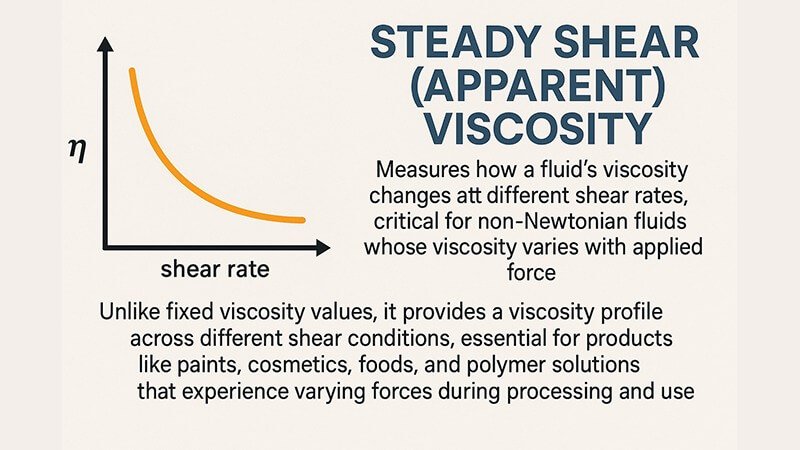

Steady shear (apparent) viscosity measures how a fluid's viscosity changes at different shear rates, critical for non-Newtonian fluids whose viscosity varies with applied force. Unlike fixed viscosity values, it provides a viscosity profile across different shear conditions, essential for products like paints, cosmetics, foods, and polymer solutions that experience varying forces during processing and use.

Steady shear viscosity reveals how your material behaves under different levels of force or agitation. This is particularly important because most industrial fluids are non-Newtonian, meaning their viscosity changes depending on how much force you apply to them.

At Martests, our rotating spindle viscometers excel at measuring apparent viscosity across multiple shear rates. By testing at different rotation speeds, we generate viscosity curves that show how materials will respond throughout your process—from gentle handling to high-speed filling operations.

I recall working with a personal care products manufacturer from Europe who couldn't understand why their body lotion worked perfectly in laboratory tests but clogged their filling equipment during production. When we tested the apparent viscosity at various shear rates, we discovered the lotion was strongly shear-thinning at low forces but exhibited unexpected thickening at the high shear rates present in their filling lines. This insight allowed them to reformulate the product while maintaining the desired consumer experience.

For non-Newtonian fluids, apparent viscosity is reported at a specified shear rate. For example, a technical data sheet might list: "Apparent viscosity: 5,000 mPa·s at 10 s⁻¹" (meaning the viscosity is 5,000 mPa·s when the shear rate is 10 reciprocal seconds). Without specifying the shear rate, the viscosity value is meaningless for non-Newtonian materials.

Common non-Newtonian behaviors include:

- Shear-thinning (pseudoplastic): Viscosity decreases as shear rate increases. Most polymer solutions, ketchup, and paint exhibit this behavior.

- Shear-thickening (dilatant): Viscosity increases with increasing shear rate. Examples include cornstarch suspensions and some specialty formulations.

- Yield stress (Bingham plastic): Materials require a minimum force to begin flowing, then behave predictably. Examples include toothpaste and certain food spreads.

- Thixotropic: Viscosity decreases over time at a constant shear rate, then recovers when at rest. Many paints and printing inks show this behavior.

When I visit customers' facilities, I often find they're measuring viscosity at only one shear rate, missing critical information about how their products will behave throughout their process. One South American distributor shared that their customer had completely eliminated production downtime after implementing multi-point apparent viscosity testing with our equipment, allowing them to predict and prevent processing issues before they occurred.

For complex formulations, I recommend measuring apparent viscosity at at least three points: a low shear rate representing storage conditions, a medium rate representing typical handling, and a high rate representing processing conditions. This provides a more complete picture of your product's behavior across its lifecycle.

Relative Viscosity: When Does Comparative Measurement Make More Sense?

Are you spending too much time on complex viscosity measurements when simpler methods would suffice? Not every application requires absolute precision, and overcomplicating your testing can waste valuable time and resources.

Relative viscosity is the ratio of a fluid's viscosity to that of a reference fluid, typically water, measured under identical conditions. This dimensionless value provides a quick, comparative assessment without absolute units, making it useful for quality control, polymer characterization, and situations where tracking changes is more important than absolute values.

Relative viscosity offers a practical approach when you need to track changes rather than know exact values. I've found this particularly useful when working with customers who need quick production floor checks rather than laboratory-precision measurements.

The concept is straightforward: if water takes 10 seconds to flow through a viscometer and your sample takes 25 seconds under identical conditions, the relative viscosity is 2.5. This simplicity makes it accessible for production staff without specialized training.

Many industries have developed standard relative viscosity tests specific to their needs:

- Polymer industry: Intrinsic viscosity and reduced viscosity measurements help characterize molecular weight and polymer chain behavior in solution.

- Brewing: The viscosity ratio of wort (the liquid extracted from mashing grains) to water helps predict brewing performance.

- Printing inks: The viscosity cup (essentially a cup with a hole in the bottom) provides a quick relative viscosity check based on drainage time.

- Adhesives and coatings: Various flow cups (Ford cup, Zahn cup) give operators immediate feedback on consistency.

I remember visiting a textile sizing operation in Southeast Asia where operators needed to maintain consistent viscosity but lacked technical training. We implemented a simple relative viscosity system using timed flow through a standardized orifice, with clear pass/fail criteria that anyone could understand and apply. This dramatically improved their quality consistency without requiring sophisticated equipment.

For polymer solutions, relative viscosity connects directly to molecular characteristics. The specific viscosity (relative viscosity minus 1) and reduced viscosity (specific viscosity divided by concentration) provide insights into polymer chain extension and interaction in solution. One European distributor uses our viscometers specifically for these polymer characterization applications in research settings.

While less precise than absolute measurements, relative viscosity has distinct advantages:

- Simplicity: Often requires minimal equipment and training

- Speed: Results available in seconds rather than minutes

- Cost-effectiveness: Less expensive equipment and maintenance

- Robustness: Less sensitive to minor variations in test conditions

At Martests, we often recommend starting with relative viscosity measurements for new quality control programs. They provide immediate value and help teams understand the importance of viscosity before investing in more sophisticated testing equipment. As processes mature, these relative measurements can be correlated with absolute values from more advanced instruments like our rotational viscometers.

Extensional Viscosity: Why Does Stretching Behavior Matter?

Are you experiencing unexpected breaks or inconsistencies during high-speed processing or product dispensing? Standard viscosity measurements might be missing critical extensional properties that control these behaviors.

Extensional viscosity measures a fluid's resistance to stretching or elongational deformation, rather than shearing forces. This property controls behavior during processes involving sudden expansions, contractions, or filament formation. It's critical for applications such as fiber spinning, spraying, coating, and food processing, particularly for polymer solutions and other complex fluids.

Extensional viscosity represents a completely different aspect of fluid behavior than the more commonly measured shear viscosity. While shear viscosity describes how fluids respond when layers slide past each other, extensional viscosity reveals how they behave when stretched or pulled apart.

This property is particularly important for processes involving:

- Fiber spinning: The stability of threads during formation

- Spraying and atomization: Droplet formation and size distribution

- Coating application: Film formation and leveling

- Food processing: String-like behavior in doughs and batters

- Printing: Ink transfer and filament behavior

I once worked with a manufacturer of adhesives who was experiencing inconsistent dispensing patterns. Their product measured perfectly on conventional viscometers but failed unpredictably during high-speed application. When we evaluated the extensional properties, we discovered that minor formulation changes were significantly affecting the stretching behavior without impacting shear viscosity. By optimizing for both properties, they achieved consistent performance.

What makes extensional viscosity particularly interesting is that fluids with similar shear viscosities can have dramatically different extensional behaviors. This is especially true for polymer solutions and other structured fluids, where molecular orientation during stretching creates resistance far exceeding what shear measurements would predict.

The Trouton ratio—the ratio of extensional viscosity to shear viscosity—quantifies this difference. For simple Newtonian fluids, this ratio is approximately 3. However, for polymer solutions and other complex fluids, it can reach into the hundreds or even thousands, explaining why some fluids form persistent strings or filaments when stretched.

Measuring extensional viscosity is more challenging than measuring shear viscosity, often requiring specialized equipment like filament stretching rheometers or opposed jet devices. At Martests, we partner with research institutions to offer comprehensive rheological characterization when customers need both shear and extensional properties analyzed.

One particularly striking example came from a Middle Eastern food manufacturer producing a traditional honey-based confection. Their product was failing quality checks despite meeting all standard viscosity specifications. When we arranged for extensional viscosity testing, we discovered that a change in their honey supplier had dramatically altered the stretching properties while maintaining similar shear viscosity. This insight allowed them to adjust their formulation to restore the desired pulling texture characteristic of their product.

For many industrial processes, the balance between shear and extensional properties determines success. Die swell in extrusion, liquid bridge stability in filling operations, and sag resistance in coatings all depend on extensional behavior that conventional viscometers don't capture. Understanding both properties gives you complete control over your product's processing and end-use performance.

Conclusion

Selecting the right viscosity measurement—dynamic, kinematic, apparent, relative, or extensional—is essential for effective quality control and process optimization. With proper viscosity characterization, you can prevent production problems and ensure consistent product performance that keeps your customers satisfied.