Are you puzzled why some fluids behave unpredictably during processing? Understanding fluid viscosity behavior can prevent costly production failures and product rejections.

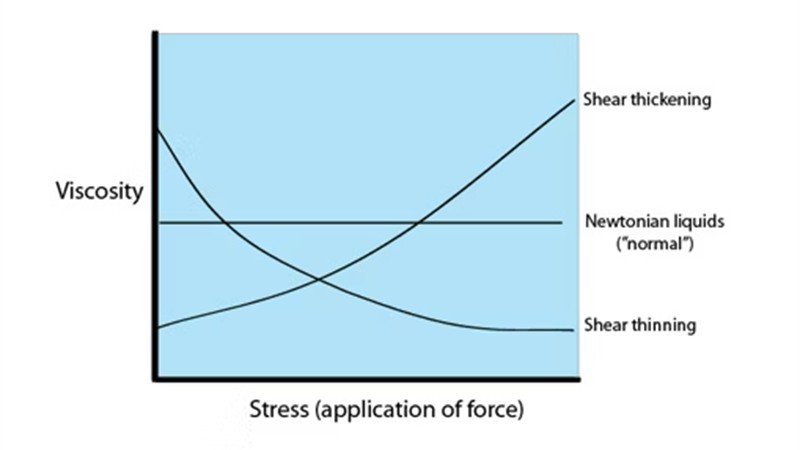

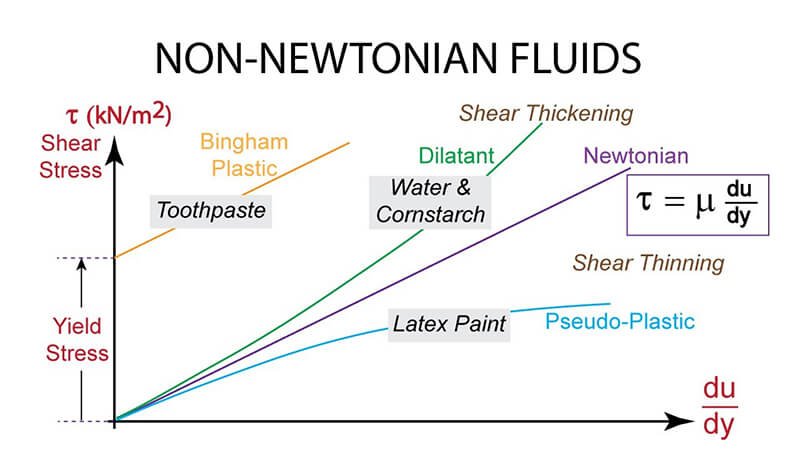

Newtonian fluids maintain constant viscosity regardless of applied force, while non-Newtonian fluids change viscosity when force is applied. Water and mineral oils exemplify Newtonian behavior, while ketchup, blood, and polymer solutions demonstrate non-Newtonian characteristics with viscosity that changes under stress.

I remember when one of our Italian distributors called with an urgent problem. Their customer was struggling with inconsistent coating thickness in a paint application. After analyzing their samples with our viscometers, we discovered they were treating a thixotropic paint as if it were Newtonian. Once they adjusted their process to account for the fluid's time-dependent viscosity, their product quality improved dramatically. Understanding fluid behavior isn't just theoretical—it directly impacts your bottom line.

Newtonian Fluids: Why Are They Called the Simplest Fluids?

Have you ever wondered why some liquids are so predictable in their behavior? Not understanding Newtonian properties can lead to incorrect equipment selection and inefficient processes.

Newtonian fluids are called the simplest fluids because they maintain constant viscosity regardless of the shear rate or force applied to them. Their flow behavior follows Newton's law of viscosity, where shear stress is directly proportional to shear rate. Common examples include water, mineral oils, glycerin, and most thin liquids.

The beauty of Newtonian fluids lies in their predictability. When I work with customers who process simple oils or solvents, I explain that these fluids will behave the same way whether flowing slowly through a pipe or being rapidly mixed. This consistency makes process design straightforward.

Newtonian fluids follow a simple mathematical relationship: τ = η × γ̇, where τ is the shear stress, η is the viscosity (a constant value), and γ̇ is the shear rate. This linear relationship is what makes these fluids so manageable in industrial applications.

At Martests, we've supplied viscometers to laboratories across Europe and Asia that specifically test for Newtonian behavior. One key insight I've gained from working with these labs is that temperature remains the primary influence on a Newtonian fluid's viscosity. While the viscosity stays constant across shear rates, it can change significantly with temperature variations.

Here's a practical table showing how some common Newtonian fluids behave at different temperatures:

| Fluid | Viscosity at 20°C (mPa·s) | Viscosity at 40°C (mPa·s) | Viscosity at 60°C (mPa·s) |

|---|---|---|---|

| Water | 1.002 | 0.653 | 0.467 |

| Glycerin | 1,412 | 284 | 81.3 |

| Olive Oil | 84 | 32 | 17 |

| SAE 10 Oil | 88 | 28 | 13 |

Understanding this temperature dependency is crucial for process design. I always advise our distributors to ensure their customers maintain consistent temperature control in applications involving Newtonian fluids. A variation of just 5°C can sometimes change viscosity by 10-15%, affecting flow rates, mixing efficiency, and final product quality.

Another important characteristic of Newtonian fluids is that they begin to flow immediately when force is applied—they have no yield stress. This makes them ideal for applications requiring immediate response to pressure changes, such as in hydraulic systems or precise dispensing operations.

Non-Newtonian Fluids: How Do They Break the Rules?

Are you experiencing inconsistent processing results with complex fluids? Many manufacturers lose time and money by failing to recognize the unique behavior of non-Newtonian fluids.

Non-Newtonian fluids break the rules by having viscosity that changes with applied force or shear rate. Their behavior falls into several categories: shear-thinning (viscosity decreases with force, like ketchup), shear-thickening (viscosity increases with force, like cornstarch in water), plastic (requires minimum force to flow, like toothpaste), and thixotropic (viscosity changes over time, like paint).

Non-Newtonian fluids are fascinatingly complex. I've worked with cosmetic manufacturers whose creams behave differently during packaging than during customer use, and food producers whose sauces need to stay on food during serving but flow easily during bottling. These seemingly contradictory requirements are actually perfect applications for carefully engineered non-Newtonian behavior.

The classification of non-Newtonian fluids is based on how their viscosity responds to different factors:

- Shear-thinning (pseudoplastic) fluids: These materials show decreased viscosity when shear rate increases. When I consult with paint manufacturers, I emphasize how this property allows paint to flow easily during application but resist dripping afterward. Other examples include blood, ketchup, and most polymer solutions.

- Shear-thickening (dilatant) fluids: These unusual materials increase in viscosity when shear rate increases. While less common in everyday products, they're finding applications in specialized protective equipment and advanced materials. A simple demonstration is cornstarch in water, which flows normally until rapidly stirred or impacted.

- Yield stress (plastic or Bingham plastic) fluids: These require a minimum force before they begin to flow. Once I helped troubleshoot an issue for a client whose tomato paste dispensing system was failing—the problem was that their system wasn't applying enough initial force to overcome the yield stress.

- Thixotropic fluids: These show time-dependent behavior, decreasing in viscosity over time when stressed, then gradually recovering when at rest. Printing inks, many paints, and certain cosmetics exhibit this behavior.

- Rheopectic fluids: The opposite of thixotropic, these rare fluids increase in viscosity over time when stressed. Some specialized lubricants use this property.

At Martests, our rotating spindle viscometers are particularly effective for characterizing these complex behaviors. By testing at different speeds (shear rates), we can generate flow curves that reveal how materials will behave under various processing conditions.

One Middle Eastern customer who produces adhesives was experiencing batch-to-batch inconsistencies. When we analyzed their products, we discovered that minor variations in raw materials were causing significant changes in the material's shear-thinning behavior. By implementing regular viscosity profiling with one of our viscometers, they were able to adjust formulations proactively and maintain consistent performance.

Why Should I Care About Fluid Classification?

Is fluid classification just academic theory, or does it have real business impact? Ignoring the practical implications of fluid behavior can lead to product failures, equipment damage, and customer dissatisfaction.

Understanding whether your fluids are Newtonian or non-Newtonian is crucial for proper equipment selection, process design, and quality control. It affects everything from pump sizing and pipeline design to mixing parameters and packaging equipment. The right knowledge can optimize production efficiency, reduce energy costs, and ensure consistent product performance.

The classification of your fluids has direct, practical implications across your entire operation. I've seen this firsthand when visiting clients' facilities. A South American distributor once told me about their customer who had installed an expensive pumping system that kept failing. The problem? They had selected pumps designed for Newtonian fluids but were processing a highly shear-thinning polymer solution.

Here are the key reasons why proper fluid classification matters to your business:

- Equipment Selection and Sizing: Pumps, pipes, valves, and mixers must be designed for the specific type of fluid behavior. For example, positive displacement pumps are often better for highly viscous non-Newtonian fluids than centrifugal pumps.

- Process Optimization: Understanding how your fluid responds to different processing conditions allows for optimization. For shear-thinning fluids, increasing the shear rate can significantly reduce apparent viscosity, potentially lowering energy costs for pumping and mixing.

- Quality Control: Viscosity profiles serve as fingerprints of proper formulation. By regularly testing against established profiles, you can quickly identify deviations in raw materials or processing conditions before they become costly problems.

- Product Development: Intentionally engineering specific non-Newtonian properties can create competitive advantages. For example, a personal care product that's easy to dispense but stays in place after application.

- Troubleshooting: When process issues arise, understanding fluid behavior provides critical insights. Is your mixing ineffective because your fluid is developing a yield stress? Is your filling line inconsistent because the product is thixotropic?

At Martests, we've equipped laboratories across four continents with viscometers specifically designed to characterize both Newtonian and non-Newtonian behavior. Our cone and plate viscometers are particularly valuable for precise characterization of non-Newtonian fluids, while our simpler rotating spindle models provide quick, reliable measurements for day-to-day quality control.

I recall visiting a cosmetics manufacturer in Southeast Asia who was struggling with inconsistent product texture. By implementing routine viscosity profiling with our equipment, they discovered that minor variations in raw material batches were causing significant changes in their product's shear-thinning behavior. This insight allowed them to adjust formulations proactively, maintaining consistent product feel despite raw material variations.

Conclusion

Understanding the difference between Newtonian and non-Newtonian fluids is vital for process optimization, equipment selection, and product quality. With proper viscosity measurement tools, you can turn this knowledge into a competitive advantage.