Struggling with inconsistent viscosity measurements and poor quality control? This uncertainty can ruin product batches and disappoint customers. Understanding your viscometer options is the first step toward reliable results.

A rotational viscometer measures fluid viscosity by determining the torque required to rotate a spindle in the sample at a known speed. The main types include rotating spindle, cone and plate, and coaxial cylinder designs, each optimized for specific applications and viscosity ranges.

Over my years of helping labs and factories, I've seen how the right instrument changes everything. A purchasing manager from Italy, Jacky, once told me, "Stefan, finding a quality instrument at a good price is my biggest challenge." He's right, and it starts with knowing what to look for. Let me walk you through the essentials.

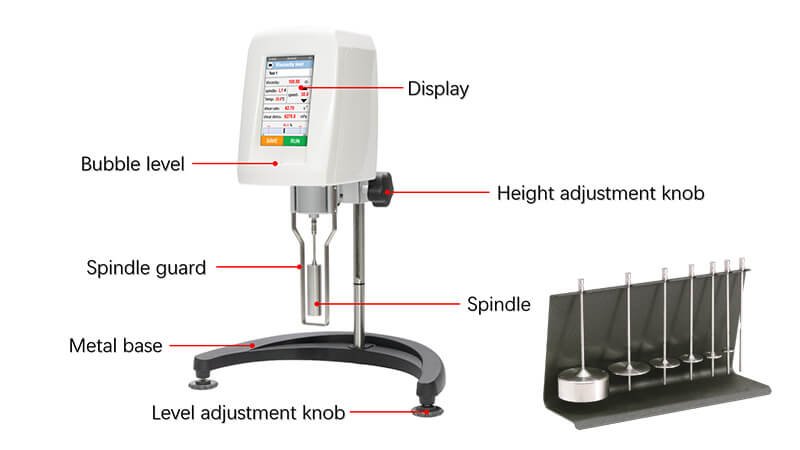

What are the Key Components of a Rotational Viscometer?

Are you tired of unreliable measurements from your current equipment? This uncertainty can disrupt your entire production schedule. Knowing your instrument's core components helps you choose better and troubleshoot faster.

A rotational viscometer has four main parts: the spindle that touches the sample, the motor that provides rotation, the torque sensor that measures resistance, and the temperature control system for accuracy.

Think of these parts as a team working together. If one part isn't right for your specific sample, the whole measurement can be off. Let’s dive deeper into each component.

Spindle

The spindle is the part that makes contact with your fluid. The shape of the spindle is critical.

- Rotating Spindle: This is the most common type. It's usually a simple disc or cylinder. You dip it into a beaker of your sample. It's great for general quality control because it's easy to use and clean.

- Cone and Plate: This system uses a flat plate and a shallow-angled cone. It requires a very small sample volume, often less than 1 mL. It’s perfect for expensive materials or when you need highly precise shear rate data, common in R&D.

- Coaxial Cylinder: This features two concentric cylinders, with the sample filling the gap between them. This design provides excellent temperature stability and is ideal for low-viscosity liquids like oils and solvents.

Motor and Torque Sensor

The motor's job is to spin the spindle at a precise, controlled speed. A good motor ensures the rotation is constant, which is necessary for repeatable results. The torque sensor measures how much force (torque) is needed to keep the spindle rotating at that speed. Thick liquids require more torque, while thin liquids require less. The viscometer's software then uses this torque reading to calculate the final viscosity value in centipoise (cP) or Pascal-seconds (Pa·s).

Temperature Control

Viscosity is highly dependent on temperature. A small change in temperature can cause a big change in viscosity. That's why a reliable temperature control system is not optional; it's essential for accurate measurements.

What Are the Main Classifications of Rotational Viscometers?

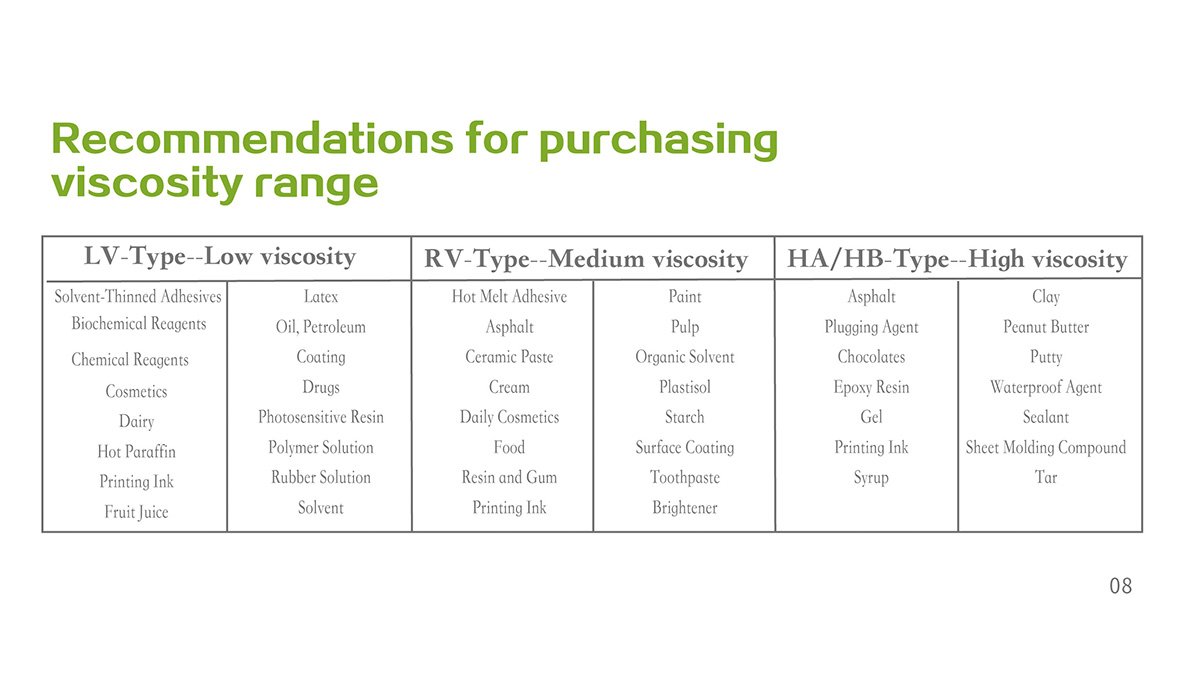

Confused by terms like LV, RV, cone-plate, or process viscometer? Choosing the wrong type is a costly mistake that leads to bad data. Let's classify them to make your choice easier.

Viscometers are grouped by their measurement system (e.g., rotating spindle), viscosity range (LV, RV, HA/HB for low, medium, high), and intended application (laboratory, process, or portable).

I always advise clients to first understand these three classification methods. It helps narrow down the options quickly. Below is a more detailed breakdown and a helpful table.

Based on Measurement System

- Rotating Spindle Viscometer: The workhorse for general QC. Simple, robust, and versatile.

- Cone and Plate Viscometer: The specialist for R&D. Needs only a tiny sample and gives absolute viscosity data.

- Coaxial Cylinder (Couette) Viscometer (Cup and Bob Viscometer): The expert for low-viscosity fluids and strict temperature control.

Based on Viscosity Range

- LV Type (Low Viscosity): For thin liquids like beverages, solvents, and light oils.

- RV Type (Medium Viscosity): The all-rounder for paints, creams, and food products like ketchup.

- HA/HB Type (High Viscosity): For thick materials like pastes, gels, and adhesives.

Based on Application

- Laboratory Viscometers: Benchtop units for precise QC and R&D in a controlled environment.

- Process Viscometers: In-line units for continuous, real-time monitoring directly in the production line.

- Portable Viscometers: Handheld, battery-powered devices for quick checks in the field or on the factory floor.

| Classification | Type | Advantages | Disadvantages | Best Applications |

|---|---|---|---|---|

| Measurement System | Rotating Spindle | Simple to use, robust, cost-effective | Needs large sample, less precise shear control | Routine QC, production checks |

| Cone and Plate | Small sample, precise shear rate, absolute viscosity | Higher cost, sensitive to particles | R&D, expensive materials, non-Newtonian analysis | |

| Coaxial Cylinder | Excellent temperature control, good for low viscosity | More complex to clean, higher cost | Solvents, oils, research, standards compliance | |

| Application | Laboratory | High precision, versatile, rich features | Stationary, higher initial cost | Quality control labs, R&D centers |

| Process | Continuous 24/7 monitoring, robust design | Lower precision than lab models, complex installation | In-line process control for food, chemicals | |

| Portable | Lightweight, battery-powered, for field use | Lower accuracy, limited features | Spot checks on-site, quick pass/fail tests |

How is Temperature Controlled in Rotational Viscometers?

Are temperature changes ruining your viscosity data? Even a one-degree shift can skew results, making your quality control unreliable. Understanding temperature control systems is key to getting accurate data every time.

Temperature is typically controlled using either a circulating water bath for broad-range stability or an electric Thermosel system for high-temperature applications. Both provide direct and stable temperature control for the sample.

I remember a client in the asphalt industry who couldn't get consistent readings. Their sample needed to be tested at 150°C. Once we installed a Thermosel system, their data became perfectly stable. The right tool makes all the difference.

Water Baths

A circulating water bath is a very common method for controlling temperature. It works by pumping temperature-controlled water through a jacketed container that holds your sample beaker.

- How it Works: An external circulator heats or cools water and pumps it around the sample.

- Pros: It offers excellent temperature stability, typically from about 10°C to 100°C. You can also see your sample during the test.

- Cons: It requires an external circulating unit, which takes up more bench space. It also needs regular water changes to prevent algae growth.

Thermosel System

A Thermosel is an electric heating system designed for high-temperature testing. It uses a special sample chamber and spindle that are heated directly by an electric controller.

- How it Works: An electric heater surrounds a small, insulated chamber holding the sample.

- Pros: It can reach very high temperatures (up to 300°C). It uses a small sample volume and is a self-contained unit, saving space.

- Cons: The sample is not visible during the test. It also typically costs more than a standard water bath setup.

What Common Accessories Can Enhance Your Measurements?

Are you struggling to measure very thin liquids or working with very small samples? Using a standard setup for these special cases often leads to inaccurate data and wasted material.

Specialized accessories like the Enhanced UL Adapter for low-viscosity fluids and the Small Sample Adapter for limited material volumes can greatly extend the capability and accuracy of your viscometer.

These are not just add-ons; they are problem-solvers. A client in pharmaceuticals once told me our Small Sample Adapter saved them thousands of dollars because they could finally test their expensive developmental drugs without wasting material.

Enhanced UL Adapter

The UL (Ultra-Low) Adapter is designed for measuring very low viscosity materials, typically below 15 cP. Standard spindles struggle to get a reliable torque reading on such thin liquids.

- What it is: A precision coaxial cylinder system that attaches to your viscometer.

- When to use it: For fluids like solvents, inks, and beverages.

- Why it works: It creates a defined measurement geometry and increases the instrument's sensitivity. This allows you to get accurate and repeatable measurements on liquids that would otherwise be difficult to test.

Small Sample Adapter

This accessory is essential when you have a limited amount of sample material to work with.

- What it is: A coaxial cylinder chamber that requires a sample volume between 2 mL and 16 mL.

- When to use it: For expensive materials like pharmaceuticals, cosmetics, or specialty chemicals.

- Why it works: It provides excellent temperature control and a defined shear environment using only a fraction of the sample needed for a standard beaker setup. This saves money and precious material.

How Do You Choose the Right Type of Rotational Viscometer?

Feeling overwhelmed by all the options and afraid of making a costly mistake? Buying the wrong instrument can set your lab back thousands of dollars and waste valuable time.

To choose the right viscometer, first define your viscosity range and sample properties. Then, assess your operating environment, check for industry standards, and evaluate the total cost of ownership, not just the price.

Follow my simple 5-step process to confidently select the perfect viscometer for your specific needs. This is the same process I use when advising clients like Jacky.

Step 1: Define Your Viscosity Range

The first question is always: "What are you measuring?" Is it thin like water or thick like honey? This determines if you need an LV, RV, or HA/HB series viscometer. Matching the instrument's range to your sample's expected viscosity is the most critical first step.

Step 2: Consider Your Sample Properties

Think about your sample. Is it a small, expensive batch? A cone-and-plate or small sample adapter might be best. Does it contain particles? A robust rotating spindle is better. Is it sensitive to temperature? Then a system with precise temperature control is a must.

Step 3: Assess Your Operating Environment

Where will you use the viscometer? A clean R&D lab has different needs than a dusty production floor. For factory use, a robust, easy-to-clean viscometer is better. For field checks, a portable, battery-powered model is the only choice.

Step 4: Review Industry Standards

Does your industry follow specific testing methods, like ASTM or ISO? Many of these standards specify the exact type of viscometer and spindle to be used. Checking this ensures your results are compliant and comparable to others in your industry.

Step 5: Evaluate Total Cost of Ownership

Finally, look beyond the initial price tag. Consider the cost of necessary accessories, maintenance, and potential training for your staff. A cheaper unit that requires expensive, frequent repairs is not a good deal. Focus on value and reliability over the long term.

Conclusion

Choosing the right rotational viscometer is vital for accurate data and consistent quality. By evaluating your sample, application, and budget, you can find the perfect tool for your needs.