Your system pressure is too high, and you think your fluid is the problem. You use the words "resistance" and "viscosity" to mean the same thing, leading to confusion and wrong solutions.

Viscosity is a fluid's internal resistance to flow (its thickness). Resistance is a much broader term for any force opposing motion in a system. Viscosity is just one part of the total resistance a fluid experiences.

This article will explain these two concepts clearly. We will look at what each one means and how they are connected. Understanding this difference is critical for anyone in the petrochemical, manufacturing, or automotive industries. Let's start by answering the main question.

Are Viscosity and Resistance the Same?

You assume viscosity and resistance are the same thing. This assumption leads to incorrect pump sizing, wasted energy, and inefficient processes that cost your company money.

No, they are not the same. Viscosity is a specific, measurable property of the fluid itself. Resistance is the total opposition to flow in an entire system, which includes viscosity plus other factors like pipe friction.

Think of it like this. Viscosity is an internal property. It describes the friction between the molecules within a fluid. Honey has high internal friction, so it has high viscosity. Water has low internal friction, so it has low viscosity.

Resistance, on the other hand, is an external and internal problem. It includes the fluid's viscosity, but it also includes every other obstacle that slows the fluid down. This includes friction against the pipe walls, restrictions from valves, and turbulence from sharp bends.

As an expert in viscosity measurement, I help clients isolate the problem. By using one of our rotational viscometers, they can get a precise number for their fluid's viscosity. If the viscosity is what they expect, but their system still has problems, they know the issue is somewhere else in the system—the "resistance" part of the equation.

| Aspect | Viscosity | Resistance |

|---|---|---|

| What it is | Internal friction of a fluid. | Total opposition to motion in a system. |

| Depends on | Fluid type, temperature. | Fluid viscosity, pipe size, pipe length, valves, bends. |

| Analogy | The "stickiness" of the fluid itself. | The difficulty of the entire journey. |

What Is Resistance?

You see "flow resistance" on an engineering report. But you are not sure what factors contribute to this single number, making it difficult to find and fix the root cause of a problem.

Resistance, in fluid dynamics, is the sum of all forces that oppose the fluid's movement through a system. It is the reason you need pressure or a pump to make a fluid flow through a pipe.

While my business is focused on viscosity, understanding overall resistance is crucial for my customers. The total resistance in a system is often called "head loss." It is a measure of the energy lost by the fluid as it moves from point A to point B.

Key Factors of Resistance

- Pipe Friction: The fluid creates friction as it rubs against the inner walls of the pipe. A rougher, older pipe will create more resistance than a smooth, new pipe.

- Pipe Dimensions: A longer pipe creates more resistance than a short one. A narrow pipe creates much more resistance than a wide one.

- Fittings and Bends: Every valve, elbow, or connector in a pipeline forces the fluid to change direction. This change creates turbulence and adds significantly to the total resistance.

What Is Viscosity?

Your product comes out too thick one day and too thin the next. You know it is a "viscosity" issue, but without a number, you cannot control it or explain the problem to your supplier.

Viscosity is a precise, scientific measurement of a fluid's "thickness" or its resistance to flow. It gives you a number, so you can set clear quality standards for your products.

This is my area of expertise. At Martests, we build the instruments that measure this critical property. Viscosity comes from the cohesive forces between molecules in a liquid. In a high-viscosity liquid like glycerin, these forces are strong, so the liquid layers do not slide past each other easily.

How We Measure Viscosity

Our main products are rotational viscometers. This category includes rotating spindle viscometers, cone and plate viscometers, and cup and bob viscometers. The working principle is simple and effective.

- A spindle (a specific metal shape) is submerged in the fluid.

- A motor turns the spindle at a constant, known speed.

- The viscometer measures the torque (the amount of force) required to keep the spindle turning.

A more viscous fluid will require more torque to turn the spindle. Our instruments translate this torque reading into a precise viscosity value, usually in units like centipoise (cP) or Pascal-seconds (Pa·s). My customers, like Jacky in Italy, use these values to ensure the paints and coatings they distribute have the exact consistency their clients need for perfect application.

How Does Viscosity Affect Resistance?

You need to start using a new, thicker raw material. You are worried your current pumps and pipes are not good enough, but you are not sure how much the change will matter.

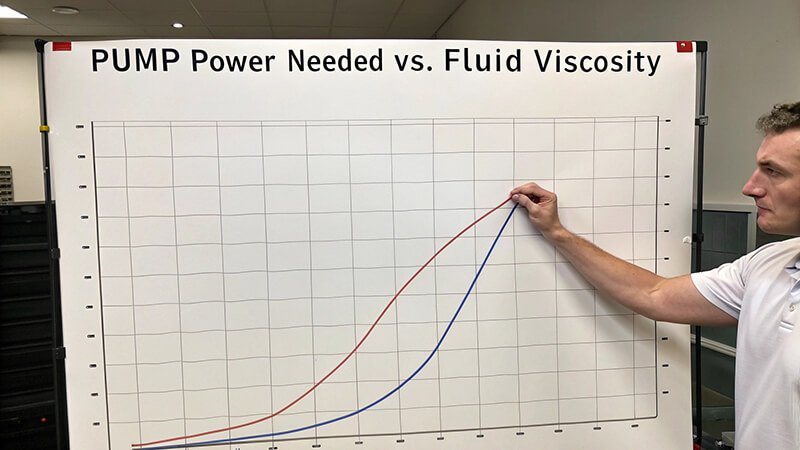

Higher viscosity directly and significantly increases the total flow resistance in a system. A more viscous fluid requires much more energy to push it through the same pipe at the same speed.

Viscosity is a major component of total resistance. The relationship is very direct. If all other factors in your system (pipe length, diameter, bends) stay the same, increasing the fluid's viscosity will increase the resistance. This means you will need more pressure to maintain the same flow rate.

The Practical Impact

This is not a small effect. For smooth, non-turbulent flow (called laminar flow), the resistance is directly proportional to the viscosity.

- If you double the viscosity of your fluid, you will need to double the pump pressure to keep the flow rate the same.

- If you switch to a fluid that is ten times more viscous, you will need ten times the pressure.

A customer in the automotive sector faced this exact issue. They were developing a new gear oil that was much more viscous to provide better protection at high temperatures. They used one of our viscometers to measure the new oil's viscosity. Their engineers used this data to calculate the new, higher resistance in the lubrication system. They realized their existing pump was not strong enough. Because they understood the link between viscosity and resistance, they were able to specify a more powerful pump before production started, avoiding a major failure.

| Fluid Viscosity | Flow Resistance (in the same pipe) | Pump Power Required |

|---|---|---|

| Low (e.g., Water) | Low | Low |

| Medium (e.g., Olive Oil) | Medium | Medium |

| High (e.g., Honey) | High | High |

| Very High (e.g., Tar) | Very High | Very High |

Conclusion

Viscosity is a fluid's thickness. Resistance is the total opposition to flow. Higher viscosity causes higher resistance. Understanding this distinction is key to designing and troubleshooting any fluid handling system efficiently.