Confused about viscosity versus plasticity? This confusion can lead to material issues. This post clarifies these distinct, crucial properties for your applications.

Viscosity describes a fluid's resistance to flow, like how "thick" honey is. Plasticity, however, is a solid's ability to permanently change shape under force without breaking, like bending metal. They are fundamentally different material properties.

Many people mix these terms up. But understanding the difference is really important. It affects how you choose materials and even how you design products. At Martests, we see this a lot with our clients who distribute lab instruments. So, let's dig into each one. We'll start with viscosity. Knowing this will help you, especially if you deal with fluids or advise clients on them, like my friend Jacky in Italy who sources viscometers.

What exactly is viscosity and how does it behave in fluids?

Ever wonder why some liquids pour slowly, others quickly? This affects product consistency and use. Understanding viscosity unlocks control over fluid behavior and quality.

Viscosity is simply a fluid's internal friction or its resistance to flowing. Think of it as the "thickness" of a liquid or gas. Higher viscosity means slower flow, like with syrup. Lower viscosity means faster flow, like water.

Viscosity is a key property of fluids (liquids and gases). It's their resistance to flow – essentially internal friction. Honey resists stirring more than water; that’s viscosity.

Defining Viscosity

Viscosity is a fluid's resistance to shear deformation, its "flow resistance." It’s a measurable physical property reflecting molecular friction. It tells us how much the molecules inside the fluid resist moving past each other.

Scientific Basis

It links shear stress (force causing flow) to shear rate (deformation speed).

- Newtonian Fluids: These fluids show a constant viscosity regardless of the shear rate applied. Water and simple oils are common examples. Their behavior is predictable.

- Non-Newtonian Fluids: For these fluids, viscosity changes with shear rate. Ketchup, for instance, becomes less viscous (thinner) when shaken (shear-thinning). Other materials, like cornstarch mixed with water, can become more viscous (thicker) under stress (shear-thickening).

We also measure dynamic viscosity (the fluid's true internal resistance to flow) and kinematic viscosity (dynamic viscosity divided by the fluid's density, which is useful when considering flow under gravity).

Key Influencers

Several factors affect a fluid's viscosity:

- Temperature: This is a major factor. Liquids usually become less viscous (flow more easily) when heated. Gases, on the other hand, tend to become more viscous with increasing temperature.

- Composition: For mixtures, the specific ingredients and their proportions are vital. Additives can be intentionally used to modify the viscosity.

- Shear Rate: This is especially crucial for non-Newtonian fluids, as their apparent viscosity can change dramatically.

Practical Examples

Viscosity is vital for many products and processes. Think of engine oils ensuring proper lubrication, paints needing to spread smoothly, and foods requiring specific textures. At Martests, our range of rotational viscometers, including specific sub-types like rotating spindle viscometers, cone and plate viscometers, and cup and bob viscometers, helps our B2B partners and their clients accurately measure viscosity. This ensures product quality for applications ranging from industrial lubricants to cosmetics, which is important for my distributor partners who need to provide reliable solutions.

What is material plasticity and why is it important for solids?

Materials break or just bend? This dictates manufacturing success. Plasticity explains how solids permanently change shape, a vital trait for forming and durability.

Plasticity is a solid material's ability to undergo permanent, non-reversible deformation when a force is applied beyond its yield strength. It's crucial for processes like metal forming or polymer molding.

Plasticity is a solid material's trait. It’s the ability to change shape permanently under force, without fracturing. When you bend a metal wire and it stays bent, that’s plasticity in action. This is a core concept in material science.

Defining Permanent Change

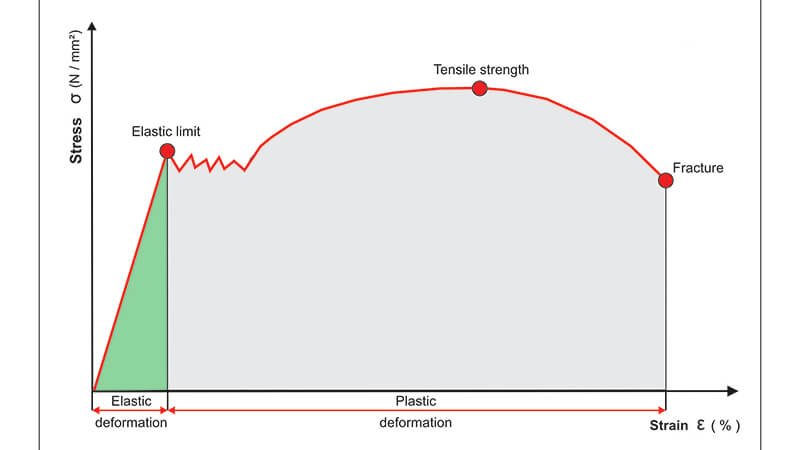

Plasticity means an irreversible deformation. This makes it different from elastic deformation, where a material returns to its original shape once the stress is removed (like a rubber band snapping back). For plastic deformation to occur, the applied stress must exceed the material's yield strength. Below this point, the material behaves elastically.

The Science Involved

The behavior of a material under stress is often shown on a stress-strain curve. This curve typically has an elastic region, then a yield point (or yield strength), followed by the plastic region where permanent deformation happens. Two key terms here are:

- Yield Strength: The amount of stress needed to start plastic deformation.

- Tensile Strength: The maximum stress a material can withstand before it starts to neck down and eventually fracture.

At a microscopic level, plastic deformation in crystalline materials like metals often involves the movement of crystal defects called dislocations, or by mechanisms like grain boundary sliding.

Factors Affecting Plasticity

Several factors influence how plastic a material is:

- Temperature: Generally, increasing the temperature increases the plasticity of many materials, especially metals. This makes them more ductile and easier to shape.

- Strain Rate: The speed at which the material is deformed can also affect its plastic behavior.

- Material Structure: The internal structure, such as crystal structure, grain size, and the presence of alloy elements or impurities, plays a significant role. Heat treatment processes can also alter plasticity.

Practical Applications

Plasticity is fundamental to many manufacturing and engineering applications. Examples include:

- Metal Forming: Processes like forging, rolling, stamping, drawing, and extrusion all rely on the plastic deformation of metals to create desired shapes.

- Polymer Shaping: Techniques like injection molding, blow molding, and thermoforming use the plastic properties of polymers.

- Geotechnical Engineering: The plastic behavior of soil is important in civil engineering for foundation design and slope stability.

Understanding plasticity helps in selecting the right materials for applications where they might be subjected to high loads. While my company, Martests, specializes in viscometers for fluid analysis, a good grasp of solid material properties like plasticity is valuable for our distributors who often handle a wide range of laboratory equipment for various material testing needs.

What are the fundamental distinctions between viscosity and plasticity?

Still mixing up flow and forming? This confusion can lead to costly errors. Let's clearly list the core differences between viscosity and plasticity for better understanding.

Viscosity describes a fluid's (liquid/gas) resistance to flow. Plasticity describes a solid's ability to deform permanently under stress. They apply to different material states, involve different mechanisms, and are measured differently.

Viscosity and plasticity both describe how materials respond to applied forces, but they are fundamentally different concepts. As someone who manufactures and supplies viscometers to B2B partners like Jacky in Italy, I believe it's crucial for distributors and their customers to be very clear on these differences to select the right testing methods and interpret results correctly.

Fundamental Contrasts

Here's a direct comparison to highlight their core distinctions:

| Feature | Viscosity | Plasticity |

|---|---|---|

| Material State | Applies exclusively to Fluids (i.e., liquids and gases). | Applies primarily to Solids. |

| Core Concept | A measure of a fluid's internal resistance to flow (internal friction). | A measure of a solid's ability to undergo permanent deformation without fracture. |

| Deformation Type | Involves continuous, irreversible flow as long as shear stress is applied. | Involves a permanent change in shape that remains after the stress is removed (if yield strength is exceeded). |

| Yield Point | Generally, no yield point; fluids will flow if any shear stress exists (for Newtonian fluids). | Has a distinct yield strength; below this, deformation is elastic (temporary). Plastic deformation occurs only above this stress. |

| Underlying Mechanism | Caused by intermolecular forces and momentum exchange between fluid layers. | Caused by mechanisms like dislocation movement or atomic rebonding within the solid's structure. |

| Measurement Focus | Quantifies the rate of flow or the resistance to it. Measured with viscometers. | Quantifies the extent of permanent deformation before failure. Assessed via tensile tests, hardness tests, etc. |

| Time Dependence | Flow is inherently a rate (deformation over time). Some fluids (viscoelastic) show complex time-dependencies. | Deformation occurs once yield is met. Some plastic phenomena like creep are time-dependent but distinct from fluid flow. |

In essence, viscosity is about how easily a fluid moves or flows. For example, our Martests viscometers are designed to measure how readily liquids like oils, paints, or food products flow. This is quite different from plasticity, which is about how much a solid material can be permanently reshaped before it breaks or fractures, like bending a steel rod. This distinction is critical. You wouldn't use a viscometer to test the plasticity of a metal component, nor would you primarily discuss the "viscosity" of a solid beam under a bending load when referring to its permanent deformation. Clear understanding helps in selecting appropriate materials and testing equipment for specific industrial applications.

Conclusion

In short, viscosity governs fluid flow; plasticity governs solid permanent shape change. Grasping these distinct properties is vital for accurate material application and testing.