Are your products inconsistent from batch to batch? Are you struggling to predict how your fluids will perform in the real world?

The purpose of a viscosity meter is to measure a fluid's resistance to flow, which is its viscosity. This measurement is essential for ensuring product quality, consistency, and performance in many industries, from manufacturing to research.

Many customers, especially those distributing lab equipment, ask me not just how our viscometers work, but why someone needs one in the first place. Understanding viscosity is fundamental to many processes. It's about control and prediction.

What is the function of the viscosity meter?

Do you need to know exactly how thick or thin a liquid is? Guessing can lead to product failures and wasted resources.

The primary function of a viscosity meter, also called a viscometer, is to provide a quantitative measurement of a fluid's internal friction or flow resistance under specific conditions like temperature and shear rate.

At my factory, we build different types of viscometers. Each one has a specific way it performs this basic function. The method used depends on the fluid and the application. Distributors like Jacky need to offer the right tool for their customers' needs.

A viscosity meter works by applying a controlled force or motion to a fluid and measuring the fluid's response. Different types of viscometers use different principles. For example, rotational viscometers1, which my factory specializes in (like rotating spindle, cone and plate, or coaxial cylinder), use a spindle or rotor that turns in the fluid. The instrument measures the torque needed to rotate the spindle at a set speed. More torque means higher viscosity. Capillary viscometers work by measuring the time it takes for a fluid to flow through a narrow tube under gravity or pressure. Falling ball viscometers measure the time it takes for a ball to fall through a known distance in the fluid. The function is always the same: quantify resistance to flow. The specific design determines which types of fluids it is best suited for and the conditions (like shear rate) under which the measurement is taken. For distributors selling to varied industries in Europe or South America, having a range of these functional types available is important.

What is the purpose of measuring viscosity?

Are you making products where consistency is critical? Without measuring viscosity, you are flying blind.

The main purpose of measuring viscosity is quality control, process optimization, and predicting a fluid's performance. It ensures products are consistent, manufacturing processes run smoothly, and materials behave as expected in their final application.

I tell my distributors that selling viscometers2 is selling consistency and reliability. Manufacturers cannot make the same product every time without monitoring key properties like viscosity.

Measuring viscosity is fundamental for quality control in countless industries. For example, in paint production, viscosity affects how the paint applies and dries. If it is too thick or thin, it will not work correctly. In the food industry, viscosity determines texture and mouthfeel, which are critical for consumer acceptance. In the pharmaceutical industry, viscosity is key for formulating stable suspensions or ensuring injectables flow correctly. Beyond QC, viscosity measurements help in research and development. Scientists develop new materials and need to understand their flow properties. It also helps engineers design and optimize manufacturing processes, such as pumping, mixing, or coating operations. Knowing the fluid's viscosity helps determine the right equipment and settings. This is why I see customers in Southeast Asia and the Middle East needing reliable viscometers for their production lines.

Why is viscosity measured at 40 degrees?

Do you need to test fluids under specific conditions relevant to their use? Temperature dramatically changes viscosity.

Viscosity is often measured at 40 degrees Celsius (or 100 degrees Celsius) for specific fluids, like lubricating oils and hydraulic fluids, because these temperatures represent standard operating or testing conditions relevant to their application in engines or machinery.

When we discuss viscometer sales with distributors targeting the automotive or heavy industry, they often ask about standard testing temperatures. It is not random; it relates directly to how the fluid is used.

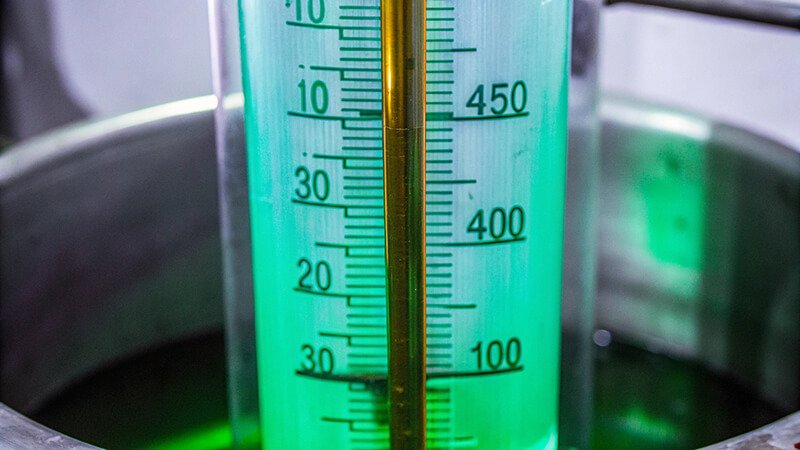

Temperature has a massive effect on viscosity3. Most fluids become less viscous (thinner) as temperature increases and more viscous (thicker) as temperature decreases. Because fluids like lubricants and hydraulic oils operate over a range of temperatures, standard test temperatures are established to provide a basis for comparison and performance specification. Measuring viscosity at 40°C gives an indication of how the oil will flow during startup or in cooler operating conditions. Measuring at 100°C indicates performance at higher operating temperatures, like inside a running engine. These specific temperatures (40°C and 100°C) are set by standards organizations like ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) for classifying and grading these types of oils (e.g., SAE viscosity grades for engine oils). Using a viscometer with precise temperature control, often with a temperature-controlled bath or a heating/cooling plate, is essential to get accurate and comparable results at these standard temperatures. My factory ensures our viscometers can integrate with or have built-in accurate temperature control systems to meet these industry standards.

What is viscosity test used for?

Are companies in industries like cosmetics, paint, or food buying viscometers from you? They are using them for specific, vital tasks.

Viscosity testing is used across diverse industries for tasks including ensuring raw material quality, controlling final product consistency, optimizing manufacturing processes, and predicting product performance and shelf-life.

I see viscosity meters going to many different types of companies. The specific reason for testing viscosity varies, but it always comes back to performance and quality.

Viscosity tests serve multiple purposes depending on the industry and application stage. In research and development, tests help formulators understand how changing ingredients or ratios affects flow properties. This is crucial for creating new products with desired textures or application characteristics. During production, viscosity tests are a key quality control checkpoint. Incoming raw materials might be tested to ensure they meet specifications. Batches of finished product are tested to confirm they match target viscosity ranges, ensuring consistency. If a batch is too thick or thin, it might need adjustment or could be rejected. In process engineering, viscosity data helps determine pump sizes, pipe diameters, mixing speeds, and coating thickness. Understanding how the fluid behaves under shear during manufacturing steps is vital for efficiency and product quality. For distributors selling to labs and factories in places like China or South America, the demand comes from these very practical needs – making sure the product works right and is the same every time.

Conclusion

Viscosity meters are essential tools for measuring fluid flow resistance. Their purpose spans quality control, process optimization, and predicting product performance in diverse industries.

-

Learn more about our rotational viscometer. ↩

-

Discovering the benefits of viscometers can help manufacturers improve their processes and product quality significantly. ↩

-

Understanding viscosity is crucial for optimizing fluid performance in various applications. Explore this link to deepen your knowledge. ↩