You notice your product isn't flowing right - too runny or too thick - but you can't pinpoint why. Without understanding viscosity, you're making quality control decisions based on guesswork rather than science.

Viscosity is a fluid's resistance to flow or deformation. Think of it as a fluid's internal friction - honey has high viscosity (flows slowly), while water has low viscosity (flows freely). This property affects how liquids behave during processing, application, and use.

In my 15+ years supplying viscometers, I've helped hundreds of manufacturers solve flow problems. Understanding viscosity isn't just academic - it directly impacts your product quality, processing efficiency, and customer satisfaction.

Dynamic Viscosity and Units?

Customers often call me confused about viscosity readings, wondering why values don't match between different testing methods. This confusion stems from not understanding the differences between viscosity types and their units.

Dynamic viscosity (absolute viscosity) measures a fluid's internal resistance to flow when force is applied. It's expressed in pascal-seconds (Pa·s) in the SI system or centipoise (cP) in the CGS system, with 1 Pa·s = 1000 cP. Water at 20°C has a dynamic viscosity of approximately 1 cP.

Dynamic viscosity is particularly important when you need to understand how a fluid behaves under actual flow conditions. Let me explain why this matters in practical applications:

Understanding Dynamic Viscosity Applications

Dynamic viscosity directly relates to the force needed to move fluids through your processing equipment. When I work with clients in industries from food production to petroleum, I emphasize how dynamic viscosity impacts:

| Industry | Why Dynamic Viscosity Matters | Common Range (cP) |

|---|---|---|

| Food | Determines mouthfeel, stability, processing | 1-100,000+ |

| Pharmaceuticals | Affects drug delivery, production, stability | 1-500,000 |

| Lubricants | Influences performance at different temperatures | 10-500 |

| Coatings | Controls application thickness, sag resistance | 50-25,000 |

The units you choose depend largely on your industry standards and equipment calibration. Most of my customers in industrial settings use centipoise, while research laboratories often prefer the SI unit pascal-seconds for scientific consistency.

Kinematic Viscosity and Units?

Many customers struggle when comparing viscosity specifications across different materials. They don't realize that density plays a crucial role in how fluids flow, which is where kinematic viscosity becomes essential.

Kinematic viscosity is dynamic viscosity divided by fluid density, measuring how quickly a fluid flows under the force of gravity alone. It's expressed in square meters per second (m²/s) in SI units or more commonly in centistokes (cSt), with 1 m²/s = 1,000,000 cSt. For water at 20°C, kinematic viscosity is approximately 1 cSt.

From my experience working with oil companies and automotive manufacturers, I've seen how critical kinematic viscosity measurements are for specific applications:

When to Use Kinematic Viscosity

Kinematic viscosity becomes especially important when gravity is the primary force moving your fluid. For instance:

| Application | Why Kinematic Viscosity Is Used | Typical Range (cSt) |

|---|---|---|

| Lubricating Oils | Industry standard for classification | 2-1000 |

| Fuel Oils | Flow through injectors relies on gravity | 1-20 |

| Hydraulic Fluids | System performance depends on flow characteristics | 10-100 |

| Ink | Print quality relates to flow under gravity | 1-50 |

I once helped a lubricant manufacturer who couldn't understand why their product passed dynamic viscosity tests but failed in field applications. The issue was they weren't accounting for the fluid's density changes at operating temperatures, which significantly altered the kinematic viscosity.

Factors Affecting Viscosity?

Product inconsistency often stems from not understanding how environmental and processing factors influence viscosity. This knowledge gap leads to quality problems and customer complaints.

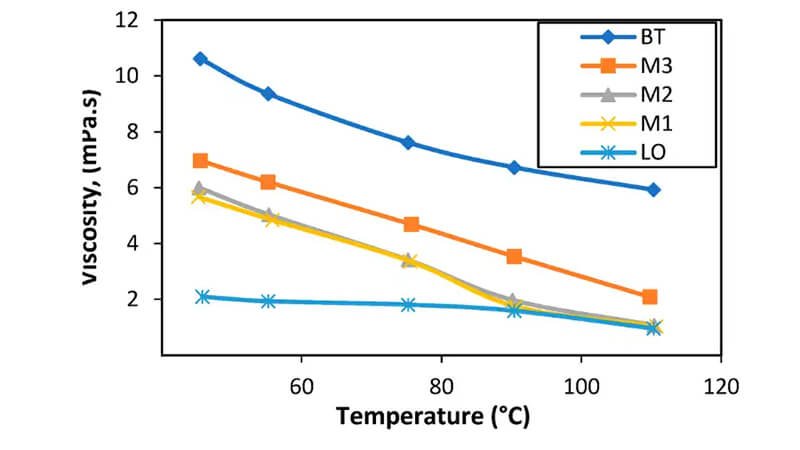

Viscosity changes with temperature, pressure, and shear rate. Generally, liquids become less viscous (thinner) when heated and more viscous (thicker) when cooled. Some materials also change viscosity when stirred or pressurized, creating challenges for processing and quality control.

Through helping clients troubleshoot their viscosity issues, I've identified several critical factors that affect flow properties:

Key Factors That Change Viscosity

Understanding these factors helps you control your process and product quality:

| Factor | Effect on Viscosity | Example |

|---|---|---|

| Temperature | Usually decreases as temperature rises | Motor oil flows better in a warm engine |

| Shear Rate | Non-Newtonian fluids change viscosity with stirring speed | Paint thins when brushed but thickens when still |

| Pressure | Increases with pressure (especially important for lubricants) | Hydraulic fluids under pressure in machinery |

| Concentration | Usually increases with higher solute concentration | Syrup becomes thicker with more sugar |

| Molecular Structure | Longer polymer chains increase viscosity | Different grades of polymer solutions |

I remember working with a food manufacturer who couldn't understand why their sauce viscosity varied between summer and winter production runs. The answer was simple - their process didn't account for seasonal temperature differences in their raw material storage area. Implementing temperature-controlled storage solved their consistency issues.

Viscosity of Newtonian and non-Newtonian Fluids?

Many production problems occur because manufacturers treat all fluids the same way. They're surprised when materials don't behave consistently during processing, leading to quality defects and equipment issues.

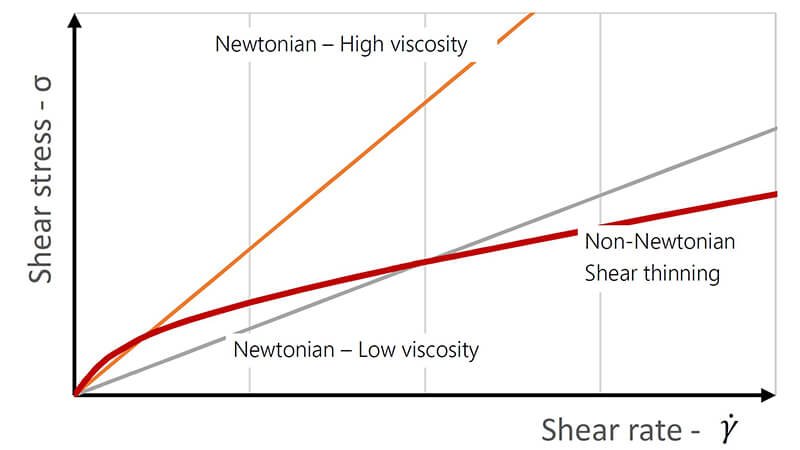

Newtonian fluids maintain constant viscosity regardless of force applied (water, oil). Non-Newtonian fluids change viscosity under force - they may thin when stirred (ketchup, paint) or thicken (cornstarch in water). Understanding your fluid type is crucial for proper processing and measurement.

Having supplied viscometers for decades, I've found that fluid classification fundamentally affects measurement approach:

Types of Non-Newtonian Behaviors

Non-Newtonian fluids exhibit several distinct behaviors that impact processing:

| Behavior | Viscosity Change | Common Examples |

|---|---|---|

| Pseudoplastic (Shear-thinning) | Decreases with increased shear rate | Ketchup, paint, blood |

| Dilatant (Shear-thickening) | Increases with increased shear rate | Cornstarch in water, silly putty |

| Thixotropic | Decreases with time at constant shear | Yogurt, some gels, printing inks |

| Rheopectic | Increases with time at constant shear | Some lubricants, gypsum pastes |

| Bingham Plastic | Requires minimum force to flow, then behaves consistently | Toothpaste, mayonnaise |

I once consulted with a cosmetics manufacturer who couldn't understand why their laboratory viscosity measurements didn't match production behavior. Their mistake was testing at a single shear rate, while their product was strongly shear-thinning. Implementing multiple-point testing solved their scaling problems.

Different Ways to Measure Viscosity?

Selecting the wrong viscosity measurement method leads to inaccurate results and costly production mistakes. Many manufacturers struggle with this decision.

Viscosity can be measured using rotational viscometers (spindle or cone/plate), capillary viscometers, falling ball methods, or vibrational instruments. The best method depends on your fluid type, required accuracy, testing conditions, and whether you need single-point or flow curve data.

Through my experience helping clients select measurement equipment, I've developed guidelines for choosing the right approach:

Selecting the Right Measurement Method

Each viscosity measurement technique has specific advantages:

| Method | Best For | Advantages | Limitations |

|---|---|---|---|

| Rotational (Spindle) | Medium-high viscosity fluids | Versatile, good for non-Newtonian fluids | Less accurate for very low viscosities |

| Cone and Plate | Precise characterization | Excellent for obtaining flow curves | Requires small sample volume |

| Capillary | Low-medium viscosity Newtonian fluids | High accuracy, industry standard for oils | Less suitable for non-Newtonian fluids |

| Falling Ball | Simple Newtonian measurements | Simple operation, low cost | Limited range, Newtonian fluids only |

| Vibrational | In-line process monitoring | Continuous measurement, rugged | Less accurate than laboratory methods |

I remember helping a paint manufacturer who was getting inconsistent quality results despite their viscosity readings looking normal. The problem was they were using a single-point test with a basic rotational viscometer, which couldn't detect important shear-thinning behavior. Switching to a more comprehensive testing protocol with multiple shear rates revealed the source of their application problems.

Conclusion

Understanding viscosity - whether dynamic or kinematic - is essential for product quality and process control. By recognizing how temperature, shear, and fluid type affect flow behavior, you can make informed decisions about measurement methods and process parameters.