Your lubricants are failing under high stress, causing engine damage. This risks costly repairs and lost customer trust. Cone and plate viscometers provide the essential data for lubricant performance.

Cone and plate viscometers are essential because they measure absolute viscosity at precise, high shear rates with small sample volumes. This accurately simulates the extreme conditions inside an engine, providing critical data on how a lubricant will perform under real-world mechanical stress.

I've worked with many lubricant manufacturers, and a common theme I see is the need for absolute certainty. When a lubricant is protecting a multi-million dollar piece of machinery, "good enough" is not an option. My client Jacky, who distributes specialty lubricants in Italy, always emphasizes that his customers demand proof of performance under stress. This proof comes from a very specific type of test that standard viscometers just can't provide. So, what makes this cone and plate setup so uniquely suited for this demanding job? Let’s explore the details.

How Does a Cone and Plate Viscometer Actually Work?

Getting inconsistent viscosity data for your lubricants? This makes it impossible to guarantee performance, risking equipment failure. The cone and plate system’s design ensures perfectly uniform and repeatable measurements.

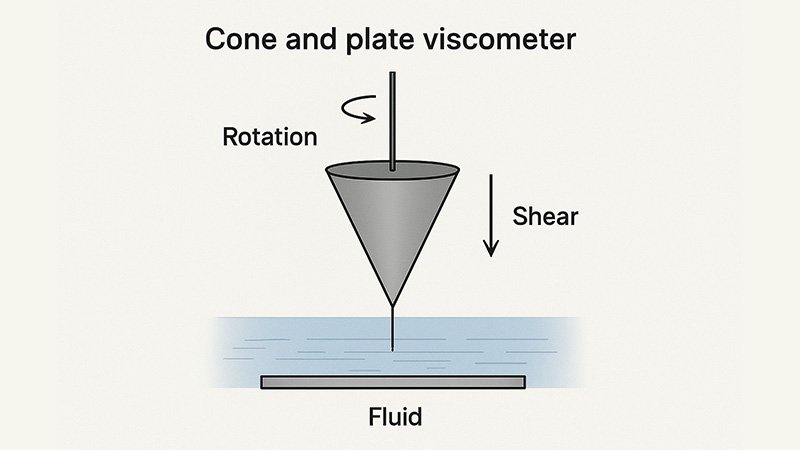

It uses a flat plate and a shallow-angled cone that spins. The tiny, precisely controlled gap between them ensures that the entire sample experiences the same shear rate. The viscometer measures the torque needed to spin the cone, calculating absolute viscosity.

The magic is in the geometry. The angle of the cone is very slight, usually less than 3 degrees. When it is lowered onto the flat plate, it creates a very narrow, uniform gap. This is the key. In a standard viscometer with a disc spindle, the fluid near the shaft moves faster than the fluid at the edge. This creates many different shear rates. The cone and plate design eliminates this problem. Every part of your tiny lubricant sample is sheared at the exact same rate. This allows us to calculate absolute viscosity, not just relative viscosity. The process is simple but precise. You place a very small sample, often less than 1 mL, onto the plate. The instrument lowers the cone to the correct gap. You set the speed and the temperature. The motor spins the cone, and a sensor measures the torque required. The instrument then uses this data to give you a direct viscosity reading in cP or Pa·s. It is a true physical measurement.

Core Components and Their Functions

| Component | Function | Why It's Critical for Lubricants |

|---|---|---|

| Cone Spindle | A precisely angled cone that rotates on the sample. | Creates a uniform shear field across the entire sample. |

| Flat Plate | A stationary, temperature-controlled surface that holds the sample. | Ensures accurate and stable temperature, which is vital for viscosity. |

| Precise Gap | The tiny, controlled space between the cone and plate. | Guarantees every particle of the lubricant experiences the same force. |

| Torque Sensor | Measures the resistance to rotation. | This measurement is directly used to calculate the absolute viscosity. |

What is Shear Rate and Why is it Critical for Lubricants?

Are you only measuring viscosity at one low speed? Your lubricant's behavior changes dramatically under engine stress, and you are missing it. Understanding shear rate is key to predicting real-world performance.

Shear rate is the speed at which a fluid is deformed by mechanical stress. For lubricants, this is critical because it simulates how fast engine parts move against each other. High shear rates, like in a running engine, can change a lubricant's viscosity.

Think of shear rate as a measure of speed and distance. Imagine two plates with a layer of oil between them. If you slide the top plate, the shear rate is its speed divided by the thickness of the oil layer. In an engine, the gap between piston rings and the cylinder wall is tiny, and the speed is very high. This creates an extremely high shear rate. Lubricants are designed to be non-Newtonian, specifically shear-thinning. This means their viscosity decreases as the shear rate increases. This is a good thing because it reduces drag and improves fuel efficiency at high speeds. But, if the viscosity drops too much, the oil film can break down. This leads to metal-on-metal contact and wear. A cone and plate viscometer allows us to test the lubricant at these very high shear rates in the lab. A standard viscometer cannot do this. We can see exactly how much the viscosity drops. This helps us determine if the lubricant will still protect the engine under extreme stress.

Shear Rate in Real-World Applications

| Application | Typical Shear Rate (s⁻¹) | What It Means |

|---|---|---|

| Oil sitting in a pan | ~0 | No stress, lubricant is at rest viscosity. |

| Stirring a liquid | 10 - 100 | Low stress, similar to pumping oil. |

| Engine Journal Bearings | 100,000 - 1,000,000+ | Extremely high stress, where performance really matters. |

Why Can't I Just Use a Standard Rotational Viscometer for Lubricants?

Using a standard viscometer seems cheaper for lubricant testing. But this gives you incomplete data that does not predict performance under real-world stress. Only a cone and plate viscometer can deliver this.

A standard rotational viscometer measures relative viscosity with a non-uniform shear field. It is great for QC checks but cannot replicate the high, specific shear rates found inside an engine. A cone and plate viscometer is designed specifically for this.

As I mentioned, a standard rotational viscometer with a disc or cylinder spindle creates a complex situation. The fluid near the spindle shaft is sheared much more intensely than the fluid at the outer edge. So what you get is an average viscosity reading across many different shear rates. For a simple fluid like honey, this is fine. But for a complex lubricant, this average is misleading. It doesn't tell you the most important thing: how the lubricant behaves at the peak shear rate it will experience in an engine. The cone and plate viscometer solves this by ensuring the shear rate is the same everywhere. Beyond this critical scientific point, there are practical benefits. Cone and plate viscometers require a very small sample. This is great when testing expensive experimental formulations. Also, the sample reaches the target temperature very quickly and stays stable, leading to faster and more accurate tests.

Direct Comparison: Cone & Plate vs. Standard Rotational

| Feature | Cone and Plate Viscometer | Standard Rotational Viscometer |

|---|---|---|

| Shear Rate | Uniform, Well-Defined | Non-Uniform, an undefined average |

| Measurement | Absolute Viscosity | Relative or Apparent Viscosity |

| Sample Volume | Very Small (< 2 mL) | Larger (up to 500 mL) |

| Best For | High-Shear R&D, lubricant specs | General QC, simple comparative checks |

Conclusion

For accurate lubricant testing that simulates real engine stress, the cone and plate viscometer is not just an option. It is the essential tool for ensuring performance and reliability.