Drilling fluids, commonly referred to as "mud," play a critical role in the success and safety of drilling operations in the oil and gas industry. These complex mixtures are responsible for a wide range of functions, including cooling and lubricating the drill bit, transporting cuttings to the surface, maintaining wellbore stability, and controlling formation pressures.

Because drilling fluids operate under extreme conditions and directly affect drilling performance, continuous testing is essential. Testing ensures that the fluid maintains its desired physical and chemical properties throughout the drilling process. Without proper testing and monitoring, the efficiency, safety, and cost-effectiveness of the operation can be severely compromised.

This article explores the importance of drilling fluid tests, the types of tests performed, and how these tests contribute to the overall success of drilling projects.

What Are the Core Functions of Drilling Fluids?

Are you unsure about what drilling mud actually does downhole? Misunderstanding its roles can lead to serious operational failures and increased expenses.

Drilling fluids perform many vital tasks. These include cleaning the hole, cooling the bit, controlling pressure, suspending cuttings, and maintaining wellbore stability. Each function is critical for successful drilling.

Understanding these functions is the first step. Now, let's see why verifying these functions through testing is not just important, but absolutely necessary for any drilling operation. This knowledge helps prevent costly mistakes.

Why Should We Test Drilling Fluids?

Wondering if all those fluid tests are really necessary? Skipping them might seem like saving time, but it can lead to much bigger problems and expenses down the line.

Testing drilling fluids is crucial because it ensures the fluid's properties are optimal for the current drilling conditions. This helps prevent wellbore instability, equipment damage, and non-productive time, ultimately saving costs and enhancing safety.

From my experience at Martests, I've seen clients face significant challenges when fluid properties drift. Testing allows us to proactively manage these properties. For instance, if the density is too low, we risk a blowout. If it's too high, we might fracture the formation. Regular checks confirm the fluid can:

- Maintain Wellbore Stability: Prevents cave-ins.

- Optimize Hydraulic Efficiency: Ensures proper cleaning and power transmission.

- Prevent Formation Damage: Protects the reservoir.

- Ensure Environmental Compliance: Meets regulatory standards.

- Control Costs: Reduces mud treatment expenses and NPT.

I always tell my customers, like Jacky from Italy, that consistent testing is an investment, not an expense. It's about maintaining control over a complex underground environment. The data from these tests guides adjustments, ensuring the fluid performs all its core functions effectively.

What Are Some Key Drilling Fluid Tests and Their Purposes?

Overwhelmed by the number of potential tests? Focusing on the key parameters can provide the most critical inforation for successful drilling.

Key tests include measuring density (mud weight), viscosity, fluid loss, pH, and solids content. Each test provides vital data about the fluid's condition and its ability to perform its specific functions effectively.

Let's break down some of these critical tests. I've seen many drilling programs succeed or fail based on how well these parameters were managed.

| Test Parameter | Purpose | Importance |

|---|---|---|

| Density (Mud Weight) | To control subsurface pressures and prevent kicks or fluid losses. | Critical for well control; too low risks a blowout, too high can fracture the formation. |

| Viscosity | To measure the fluid's resistance to flow, affecting its hole cleaning and solids suspension capabilities. | Crucial for carrying cuttings to the surface and preventing them from settling when circulation stops. |

| Fluid Loss | To measure the amount of liquid phase lost to permeable formations. | Minimizing fluid loss protects formations and maintains wellbore stability. |

| pH / Alkalinity | To control corrosivity and the effectiveness of certain additives. | Important for protecting equipment and ensuring additives perform as expected. |

| Solids Content | To determine the percentage of solids, both desirable and undesirable. | High undesirable solids can increase density, viscosity, and wear on equipment. |

| Sand Content | To measure the amount of abrasive sand particles. | High sand content causes excessive wear on pumps, drill string, and bits. |

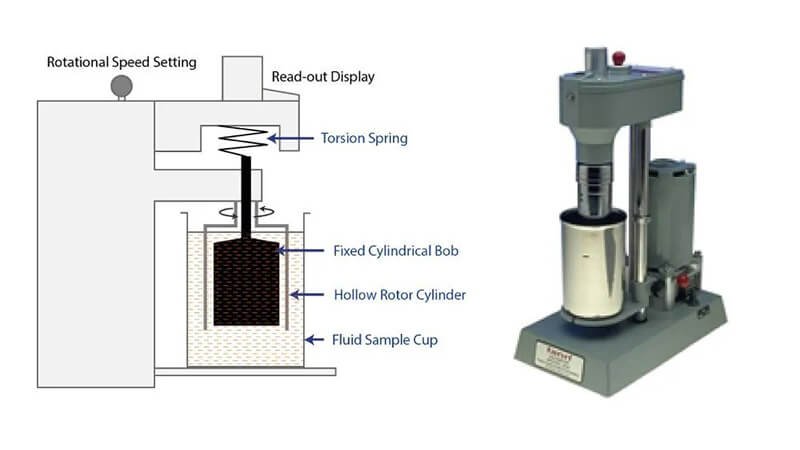

At Martests, we place a special emphasis on viscosity measurement. Viscosity is not just a single number; it’s about the fluid's flow behavior under different shear conditions (rheology). It directly impacts how well the mud cleans the hole. If viscosity is too low, cuttings fall back. If it's too high, pump pressures increase, and an excessively thick filter cake can form. Our drilling fluid viscometers, including robust rotational models, are designed for the harsh conditions of field and lab testing. They provide the accurate, reliable data needed to optimize hole cleaning and hydraulic performance, ultimately leading to more efficient drilling and reduced non-productive time for our clients. We ensure our instruments give you the precise readings you need to make informed decisions.

Conclusion

Testing drilling fluids is not optional. It's a fundamental practice for safe, efficient, and cost-effective drilling operations. It ensures the fluid performs all its vital functions.