Are you struggling to understand why small system changes greatly affect fluid behavior? This confusion can lead to inefficient processes and inconsistent product quality. The answer is in the fluid layers.

Viscosity depends on the distance between fluid layers because this distance determines the fluid's internal friction. A smaller distance creates higher friction and resistance to flow, while a larger distance reduces this friction, requiring less force to move the fluid.

In my work at Martests, I've seen this concept challenge even experienced engineers. It seems abstract, but it is the key to controlling everything from paint application to oil lubrication. Understanding this principle helps my clients, who are often distributors like Jacky in Italy, explain the value of precise measurement to their own customers. To really grasp this, we need to look closer at what is happening on a microscopic level within the fluid.

What is the fundamental principle behind fluid friction?

Does the term 'internal friction' in fluids seem vague to you? Without understanding it, you are just guessing how a fluid will behave under different conditions. Let’s clarify this core principle.

The fundamental principle is cohesive force. Molecules within a fluid are attracted to each other. When one layer of fluid moves relative to another, these forces create a dragging effect, or internal friction, which we measure as viscosity.

Think of a deck of cards. It is easy to slide the whole deck across a table. But it is harder to slide the top card across the one beneath it. This resistance is like the internal friction in a fluid. The fluid acts like countless thin layers, and the cohesive forces between molecules create friction when these layers try to slide past one another. This is exactly what our Martests rotating spindle viscometers measure. The force, or torque, needed to turn the spindle against this drag gives us a precise viscosity value. This is why honey is much more viscous than water. The cohesive forces between honey's complex sugar molecules are incredibly strong compared to the forces between simple water molecules.

How does the distance between layers influence shear rate and stress?

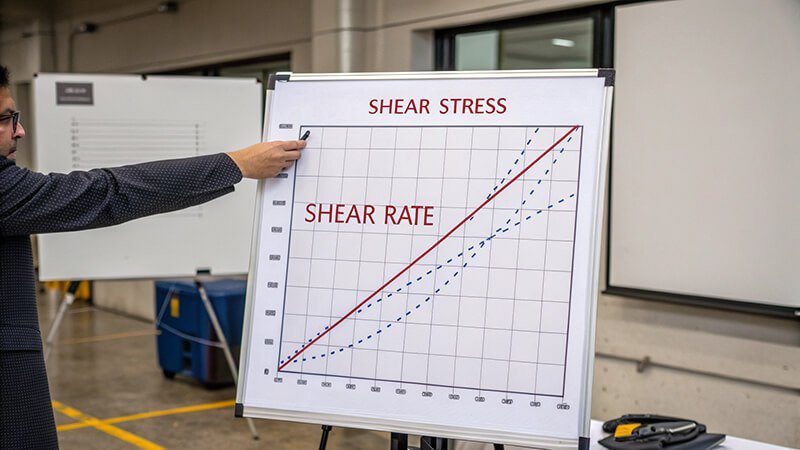

Are terms like 'shear rate' and 'shear stress' making your head spin? Not knowing the difference can lead to misinterpreting viscometer readings and choosing the wrong material for a job. Let's break them down simply.

Shear stress is the force applied to the fluid. Shear rate is the resulting speed difference between layers divided by the distance between them. A smaller distance means a higher shear rate for the same speed, increasing internal resistance.

Let's make this simple. Shear stress is the "push" you give the fluid. Shear rate is how fast the fluid "moves" or deforms in response. The relationship is key: Viscosity = Shear Stress / Shear Rate. The distance between layers is part of the shear rate calculation. Imagine two plates with fluid between them. If you move the top plate, the fluid deforms. If the gap is small, the rate of deformation is high. If the gap is large, the rate is lower for the same speed. This is critical for non-Newtonian fluids, like ketchup or paint, whose viscosity changes with shear rate. Our cone and plate viscometers are perfect for this, as they maintain a constant shear rate across the sample, giving very reliable data for such materials.

| Concept | Definition | Importance |

|---|---|---|

| Shear Stress | The force applied per unit area (the push). | It is the cause of fluid flow. |

| Shear Rate | The rate of change of velocity at which one layer of fluid passes over an adjacent layer. | It is the effect of the applied stress. |

| Viscosity | The ratio of Shear Stress to Shear Rate. | It defines the fluid's resistance to flow. |

Why does this matter for real-world industrial applications?

Is it hard to connect these theories to your daily business operations? Ignoring these principles can lead to production failures, inconsistent product batches, and unhappy end-customers for my distributor partners. Let's see how this affects your bottom line.

This matters because controlling the distance between fluid layers—or understanding its effects—is crucial for product performance and process efficiency. It impacts lubrication, coating thickness, and how easily a product can be pumped.

This is where theory meets reality. I often discuss these three examples with distributors to show the practical value of accurate viscosity measurement.

1. Lubrication

Think of engine oil. It forms a thin film between moving metal parts. The distance is tiny. The oil's viscosity must be perfect for that specific gap to prevent metal-on-metal contact. If the viscosity is too high, it creates drag and wastes energy. If it's too low, the film breaks.

2. Coatings and Paints

When paint is applied with a roller, the distance between the roller and the wall defines the shear environment. The paint's viscosity must be low enough to flow evenly in this small gap but high enough to not drip or sag afterward.

3. Pumping and Mixing

In a pipe, fluid moves fastest at the center and slowest at the wall. This velocity difference across the pipe's diameter is all about layer distance. Understanding this helps engineers calculate the energy needed to pump a liquid, which is vital for process efficiency in chemical or food manufacturing.

For my clients, selling a Martests viscometer is about providing control over these critical factors.

Conclusion

The distance between fluid layers directly controls internal friction. Mastering this concept is key to optimizing industrial processes, ensuring product quality, and achieving consistent, reliable manufacturing results.