Struggling with inconsistent paint batches? This leads to application problems like sagging or poor leveling, frustrating painters and harming your brand. The Stormer viscometer is the industry-standard solution.

The paint industry uses Stormer viscometers because they measure viscosity in Krebs Units (KU), which directly simulates the feel and performance of paint during real-world brushing or rolling. This makes them essential for ensuring consistent application quality according to standards like ASTM D562.

Drawing from my years of supplying viscometers, I've seen how vital the Stormer is to paint manufacturers. My client Jacky, a distributor in Italy, often tells me his paint industry customers won't even consider another type of instrument for their final QC. The reason is simple: the Stormer viscometer's ability to simulate real-world application conditions makes it indispensable. This precision ensures manufacturers can maintain product reliability across every batch. This ultimately satisfies the painters using the product and strengthens the brand's reputation in a very competitive market. Let's break down why this specific tool is so important.

How Does a Stormer Viscometer Actually Work?

Confused by how a spinning paddle can give such critical data? This simple-looking mechanism is surprisingly clever and perfectly designed for its job. Let me explain the process.

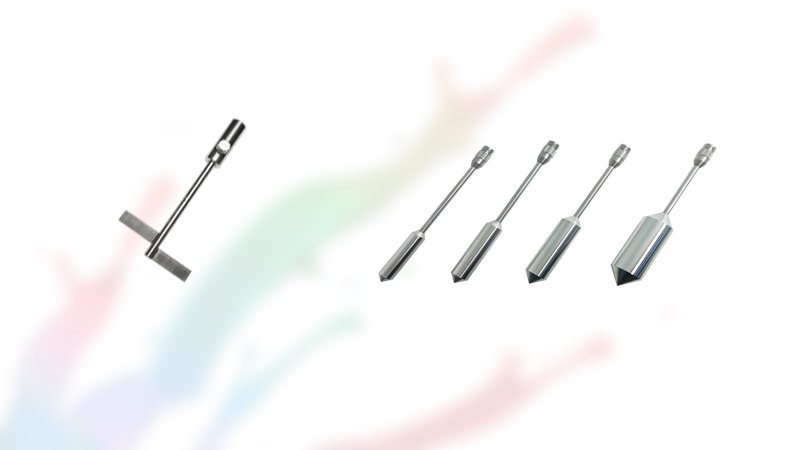

A Stormer viscometer uses a special paddle-shaped spindle that rotates at a fixed speed of 200 rpm. The instrument measures the force, or load, required to maintain this speed. This force is then automatically converted and displayed in Krebs Units (KU).

Unlike a standard rotational viscometer that measures the resistance (torque) at various speeds you select, the Stormer viscometer does the opposite. It always aims for a constant speed of 200 rpm and measures how much effort it takes to get there. The core of the instrument is a precision motor that drives the unique paddle spindle. When you submerge this paddle in a paint sample and start the test, the motor works to spin it at exactly 200 revolutions per minute. A sensor inside measures the load (in grams) the motor needs to exert to overcome the paint's resistance. More "effort" means a thicker, more viscous paint. The instrument's software instantly converts this gram value into the famous Krebs Units (KU), which is the number that matters to every paint formulator. This entire process is standardized under the method ASTM D562, which is the global benchmark for paint consistency testing.

Key Components of a Stormer Viscometer

| Component | Function | Why It's Important for Paint |

|---|---|---|

| Paddle Spindle | Unique paddle shape creates complex shear forces in the sample. | This shape mimics the complex action of a brush or roller moving through paint. |

| Constant Speed Motor (200 rpm) | Drives the spindle at the industry-standard speed. | Provides a consistent and repeatable testing condition for all paint samples. |

| Load Sensor | Measures the force (in grams) needed to maintain 200 rpm. | This is the raw data that directly relates to the paint's resistance to being applied. |

| KU Converter | Internal software or a chart that converts the gram load to Krebs Units. | Translates the physical measurement into the industry's common language for viscosity. |

What Are Krebs Units (KU) and Why Are They Essential for Paint?

Are you still reporting paint viscosity in centipoise (cP)? You might be using the wrong language for the industry, causing confusion and miscommunication with your customers and suppliers.

Krebs Units (KU) are a unique viscosity scale used almost exclusively in the paint and coatings industry. They measure a paint's consistency at a mid-range shear rate, which directly correlates to its application properties like ease of brushing and flow.

The Krebs Unit scale was developed to solve a practical problem: formulators needed a number that matched a painter's real-world experience. A painter doesn't care if a paint's viscosity is 1,000 cP; they care if it feels right on the brush, doesn't drip, and covers the wall smoothly. The KU value provides exactly that. It's an empirical scale, meaning it was developed through observation and experience, not pure physics. The goal was to create a value where, for example, a paint between 95 and 105 KU would consistently have a good "feel" during application. This is why KU is the main language of paint QC. When a paint manufacturer sets a specification, it's almost always a KU range. This ensures that every batch produced will behave the same way for the end-user, which is critical for brand consistency.

Typical KU Ranges for Common Paints

| Paint Type | Typical KU Range | What it Means for Application |

|---|---|---|

| Interior Latex (Matte) | 90 - 100 KU | Good balance of flow and sag resistance. Easy to apply with a roller. |

| Gloss Enamel | 80 - 90 KU | Thinner consistency allows for better leveling, creating a smooth, high-gloss finish. |

| Exterior Primer | 98 - 108 KU | Thicker consistency to fill imperfections and prevent sagging on vertical surfaces. |

| Industrial Coatings | 100 - 120+ KU | Very high viscosity for specific heavy-duty application methods and thick film builds. |

Why Is the Stormer Better than Other Viscometers for Paint Testing?

Thinking of using a standard rotational viscometer for paint? While you can get a number, you'll miss the key data that actually predicts real-world performance on a wall.

The Stormer viscometer is superior for paint testing because its paddle spindle and KU measurement directly simulate the complex shearing action of brushing or rolling. A standard viscometer measures a single point, which doesn't capture the true behavior of paint.

The secret lies in understanding that paint is a non-Newtonian fluid. Specifically, it's shear-thinning. This means its viscosity changes depending on the force applied to it. When paint is just sitting in the can, it's thick. When you apply force with a fast-moving brush, it becomes thinner, allowing it to flow. A standard rotational viscometer, like our Martests DV series, is an excellent scientific tool. It can tell you the exact viscosity in centipoise (cP) at a precise rotational speed. For example, it might tell you the viscosity is 2,000 cP at 10 rpm. This is useful data for R&D, but it doesn't tell the whole story for a painter. The Stormer viscometer, with its unique paddle design, doesn't just shear the fluid at one simple rate. It churns and mixes it in a way that is much closer to the action of a loaded paintbrush. This is why the resulting KU value is so powerful—it’s a single, reliable number that predicts that complex, real-world behavior.

Stormer vs. Standard Rotational Viscometer

| Feature | Stormer Viscometer | Standard Rotational Viscometer |

|---|---|---|

| Primary Use Case | Paint & Coatings QC (ASTM D562) | General-purpose QC/R&D for a wide variety of fluids |

| Measurement Unit | Krebs Units (KU) | Centipoise (cP) or Pascal-seconds (Pa·s) |

| Spindle Type | Paddle | Disc, Cylinder, Cone |

| Correlation to Application | High. Designed to mimic brushing/rolling. | Low/Indirect. Measures viscosity at a fixed, simple shear rate. |

I've had clients try to save money by using a standard viscometer for their paint QC. They get precise cP data, but their customers still complain about inconsistent application. Once they invest in a Stormer viscometer, the KU values from their lab finally match the feedback from the field.

Conclusion

The Stormer viscometer is the paint industry's essential tool because it speaks the language of application, using Krebs Units to guarantee consistent quality from the factory to the wall.